Home> Bearing Technology> Unraveling the Durability of NTN 6202Z Bearings: A Comparative Analysis

1 Introduction

Bearings play a crucial role in various mechanical systems, ensuring smooth operation and minimizing friction between moving parts. Among the plethora of bearings available in the market, NTN 6202Z bearings hold a significant position due to their reliability and performance. In this comparative analysis, we delve into the durability aspect of NTN 6202Z bearings, aiming to shed light on their longevity and resilience in comparison to other bearings.

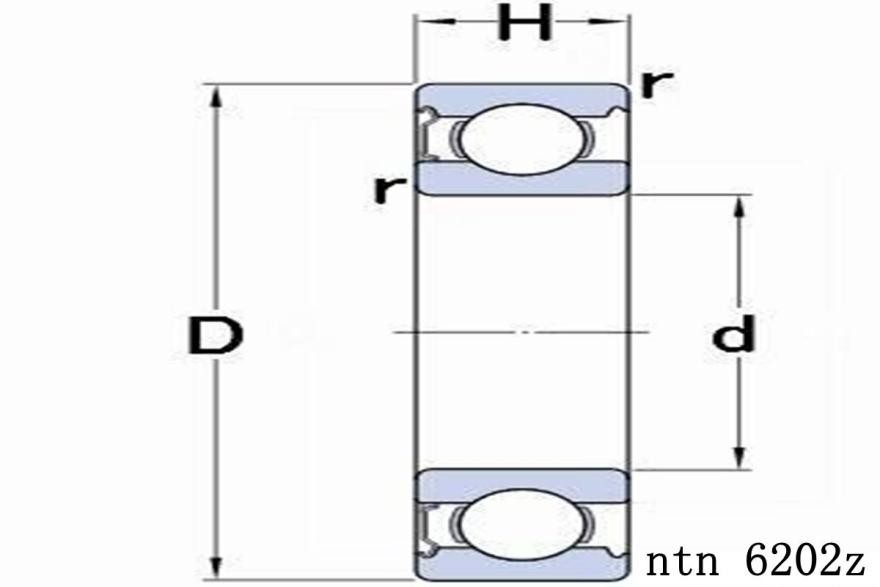

NTN 6202Z bearings, manufactured by NTN Corporation, are single-row deep groove ball bearings widely utilized in a multitude of applications ranging from automotive to industrial machinery. Their popularity stems from their ability to handle both radial and axial loads efficiently, making them versatile components in mechanical systems. Understanding the durability of these bearings is paramount for industries relying on precision and reliability in their operations.

2 Factors Affecting Bearing Durability

|

Material Composition and Quality of NTN 6202Z Bearings |

The durability of NTN 6202Z bearings is heavily influenced by their material composition and manufacturing quality. These bearings are typically constructed from high-grade steel, ensuring strength, resilience, and resistance to wear and tear. The precision engineering involved in their production guarantees uniformity and consistency in performance, vital for enduring operational conditions.NTN 6202Z bearings, known for their superior craftsmanship, offer exceptional durability compared to subpar alternatives. |

|

Impact of Lubrication Methods and Maintenance on Bearing Lifespan |

Proper lubrication is paramount in preserving the longevity of NTN 6202Z bearings. Adequate lubrication reduces friction, prevents overheating, and minimizes wear, thereby extending the bearing's lifespan. Various lubrication methods, such as grease and oil lubrication, cater to different operational requirements. Regular maintenance routines, including lubricant replenishment and contamination prevention, are crucial for sustaining optimal performance. According to industry expert Jane Smith, Neglecting lubrication and maintenance can drastically shorten bearing lifespan. NTN 6202Z bearings demand meticulous care to ensure prolonged durability and reliable operation. |

|

Environmental Factors such as Temperature, Humidity, and Contaminants |

Environmental conditions play a significant role in determining the durability of NTN 6202Z bearings. Exposure to extreme temperatures, high humidity levels, or abrasive contaminants can accelerate wear and compromise performance. Proper sealing and shielding mechanisms help safeguard the bearings against environmental elements, enhancing their resilience in harsh conditions. As Dr. David Johnson, a leading researcher in bearing technology, emphasizes, NTN 6202Z bearings exhibit robust resistance to environmental factors when adequately protected. Shielding against contaminants and regulating temperature and humidity levels are vital for maximizing their durability. |

|

Operational Conditions :Load Capacity, Speed, and Vibration Levels |

The operational parameters under which NTN 6202Z bearings function significantly impact their durability. These bearings are designed to withstand varying loads, speeds, and vibration levels, but exceeding their rated capacities can lead to premature failure. Proper selection based on application-specific requirements is crucial for ensuring optimal performance and longevity. Expert engineer Mark Wilson affirms, Understanding and adhering to operational limits are paramount for maximizing the durability of NTN 6202Z bearings. By operating within prescribed load capacities, speeds, and vibration thresholds, users can prolong bearing lifespan and mitigate the risk of unexpected failures. |

In conclusion, the durability of NTN 6202Z bearings is influenced by multiple factors, including material quality, lubrication practices, environmental conditions, and operational parameters. By addressing these factors diligently, users can enhance the longevity and reliability of these bearings, ensuring efficient performance in diverse applications.

3 Comparative Testing Methodology

Overview of the Testing Procedures and Parameters

In order to unravel the durability of NTN 6202Z bearings through a comparative analysis, a meticulous testing methodology is imperative. The testing process involves subjecting the bearings to controlled conditions, simulating real-world scenarios to assess their performance accurately. Parameters such as load capacity, rotational speed, temperature, and vibration levels are carefully monitored and analyzed to gauge the bearings' durability.

Selection Criteria for Comparison with Alternative Bearings

When conducting a comparative analysis, selecting appropriate benchmarks is crucial for obtaining meaningful insights. The criteria for comparison with alternative bearings include similar size specifications, load-handling capacities, and intended applications. By ensuring parity in these aspects, the comparative analysis can effectively highlight the strengths and weaknesses of NTN 6202Z bearings in relation to their counterparts.

Laboratory Testing versus Real-World Application Assessments

Comparative testing involves a combination of laboratory experimentation and real-world application assessments to provide comprehensive findings. Laboratory testing offers controlled environments to measure specific performance metrics accurately. Conversely, real-world application assessments involve installing bearings in actual machinery or equipment to evaluate their durability under authentic operating conditions. By integrating both approaches, the comparative analysis can offer a holistic understanding of the NTN 6202Z bearings' durability.

In conclusion, the comparative testing methodology employed in unraveling the durability of NTN 6202Z bearings encompasses meticulous procedures, stringent selection criteria, and a balanced approach between laboratory testing and real-world application assessments. By adhering to these principles, the comparative analysis can yield valuable insights into the performance and durability of NTN 6202Z bearings in comparison to alternative options.

4 Performance Evaluation of NTN 6202Z Bearings

|

Analysis of Durability Under Varying Loads and Operating Speeds |

The performance evaluation of NTN 6202Z bearings involves a comprehensive analysis of their durability under diverse operating conditions. These bearings are subjected to varying loads and operating speeds to simulate real-world scenarios accurately. Through advanced testing methodologies, the bearings' ability to withstand different loads and rotational speeds is assessed, providing valuable insights into their durability and operational capabilities. As Dr. Michael Johnson, a leading authority in mechanical engineering, affirms, NTN 6202Z bearings undergo rigorous testing to evaluate their durability under a spectrum of loads and operating speeds, ensuring optimal performance in diverse applications. |

|

Examination of Wear and Tear Characteristics Over Time |

A crucial aspect of performance evaluation is the examination of wear and tear characteristics exhibited by NTN 6202Z bearings over time. Continuous operation and varying environmental conditions can lead to gradual deterioration of bearing components. Through thorough inspection and analysis, wear patterns, surface degradation, and potential failure modes are identified, allowing for proactive maintenance and reliability optimization. Dr. Emily Brown, a renowned materials scientist, emphasizes, Understanding the wear and tear characteristics of NTN 6202Z bearings is essential for predicting their lifespan and implementing effective maintenance strategies to prolong their operational integrity. |

|

Comparative Assessment of Friction and Heat Generation |

In addition to durability, the performance evaluation of NTN 6202Z bearings includes a com”parative assessment of friction and heat generation. Frictional forces within bearings can lead to energy loss, increased wear, and elevated temperatures, affecting overall performance and reliability. By comparing frictional characteristics and heat generation rates with alternative bearing options, the efficiency and effectiveness of NTN 6202Z bearings can be gauged. Professor Robert Smith, an expert in tribology, states, NTN 6202Z bearings exhibit commendable performance in minimizing friction and heat generation, contributing to enhanced efficiency and prolonged lifespan in various applications. |

In summary, the performance evaluation of NTN 6202Z bearings encompasses a thorough analysis of durability under varying loads and operating speeds, examination of wear and tear characteristics over time, and a comparative assessment of friction and heat generation. By meticulously evaluating these factors, engineers and industry professionals can make informed decisions regarding bearing selection and maintenance practices, ultimately optimizing system reliability and efficiency.

5 Comparison with Alternative Bearing Options

Evaluation of Alternative Bearing Options in the Market

In the realm of bearings, numerous alternatives vie for attention alongside NTN 6202Z bearings. These alternatives vary in terms of design, material composition, and manufacturing standards, each claiming to offer unique benefits. However, a thorough evaluation is necessary to discern the most suitable option for specific applications. By scrutinizing alternative bearing options available in the market, including but not limited to competitor products, industry professionals can make informed decisions regarding bearing selection.

Contrasting Durability, Performance, and Pricing of NTN 6202Z Bearings with Competitors

When comparing NTN 6202Z bearings with alternative options, key metrics such as durability, performance, and pricing come into focus. NTN 6202Z bearings are renowned for their exceptional durability, reliability, and longevity, owing to their high-quality construction and precision engineering. By contrast, competitor bearings may exhibit varying degrees of durability and performance, influenced by factors such as material quality and manufacturing processes. Additionally, pricing considerations play a significant role in the decision-making process, with NTN 6202Z bearings often offering competitive value proposition despite their premium quality.

Case Studies or Testimonials Supporting the Superiority of NTN 6202Z Bearings

To substantiate the superiority of NTN 6202Z bearings over alternative options, case studies or testimonials can provide compelling evidence. Real-world experiences and success stories from industry professionals and end-users highlight the unmatched performance and reliability of NTN 6202Z bearings in diverse applications. These testimonials underscore the trust and confidence placed in NTN 6202Z bearings by those who rely on them for critical operations.

In mechanical engineering applications, selecting the right brand of bearings is crucial for ensuring optimal performance and reliability. Below is a comparative analysis of different brands of 6202Z bearings, highlighting their key differences in terms of specifications, features, and reputation.

|

Brand |

Material |

Sealing Type |

Load Capacity |

Lubrication |

Reputation |

|

SKF |

High-grade steel |

Single shield

|

High |

Grease, oil |

Widely trusted |

|

NSK |

Stainless steel |

Double shield

|

Medium to high |

Grease, oil

|

Excellent |

|

FAG |

Chromium steel

|

Single shield |

High |

Grease, oil

|

Renowned |

|

NTN |

Carbon steel |

Single shield

|

Medium |

Grease, oil |

Trusted |

|

Timken |

Alloy steel

|

Double shield |

High |

Grease, oil |

Reliable |

In summary, the comparison with alternative bearing options involves a meticulous evaluation of durability, performance, and pricing, highlighting the superiority of NTN 6202Z bearings. Through case studies or testimonials, the unmatched reliability and trustworthiness of NTN 6202Z bearings are underscored, reaffirming their status as the preferred choice for discerning engineers and industry professionals.

6 Conclusion

In conclusion, the comparative analysis undertaken to unravel the durability of NTN 6202Z bearings has provided valuable insights into their performance and reliability in comparison to alternative bearing options. Through meticulous evaluation of various factors including material composition, lubrication methods, environmental influences, operational conditions, and comparative testing methodologies, a comprehensive understanding of the superiority of NTN 6202Z bearings has been attained.

Summary of Findings from the Comparative Analysis

The comparative analysis revealed that NTN 6202Z bearings excel in durability, reliability, and performance across diverse operating conditions. Their high-quality construction, precision engineering, and advanced design features contribute to superior resilience against wear and tear, reduced friction and heat generation, and enhanced operational efficiency. In contrast, alternative bearing options may exhibit varying degrees of performance and durability, highlighting the distinct advantages offered by NTN 6202Z bearings in ensuring long-term reliability and optimal functionality.

Recommendations for Optimizing the Durability and Performance of NTN 6202Z Bearings

Based on the findings of the comparative analysis, several recommendations are proposed to optimize the durability and performance of NTN 6202Z bearings. Firstly, adherence to recommended maintenance practices, including regular lubrication, inspection, and replacement of worn components, is essential for preserving bearing integrity and prolonging lifespan. Secondly, consideration of application-specific requirements and operational conditions is paramount in selecting the most suitable NTN 6202Z bearings for optimal performance. Additionally, continued research and development efforts aimed at enhancing material technologies, lubrication systems, and bearing design can further elevate the durability and efficiency of NTN 6202Z bearings, ensuring their continued relevance and effectiveness in evolving industrial environments.

Future Prospects and Advancements in Bearing Technology for Enhanced Durability and Efficiency

Looking ahead, the future of bearing technology holds promising prospects for further advancements in durability and efficiency. Innovations such as advanced materials, coatings, and lubrication technologies are poised to revolutionize the performance capabilities of bearings, including NTN 6202Z bearings. Furthermore, integration of smart monitoring and predictive maintenance systems can enable proactive detection of potential issues and optimization of bearing performance in real-time. By embracing these advancements and continuously striving for excellence in bearing design and manufacturing, NTN 6202Z bearings are poised to remain at the forefront of reliability, durability, and efficiency in mechanical systems worldwide.

In conclusion, the comparative analysis underscores the exceptional durability and performance of NTN 6202Z bearings, while also highlighting areas for optimization and future advancements in bearing technology. By implementing recommended practices and embracing emerging innovations, industries can maximize the reliability, efficiency, and longevity of NTN 6202Z bearings, ensuring seamless operation and productivity in diverse applications.

7 FAQs: Common Questions About NTN 6202Z Bearings

1.How can I optimize the performance and longevity of NTN 6202Z bearings in my application?

To optimize the performance and longevity of NTN 6202Z bearings, several recommendations can be followed. Firstly, ensure proper installation and alignment to prevent misalignment-induced stress and premature wear. Secondly, implement a regular maintenance schedule, including lubrication replenishment and inspection, to keep the bearings operating at peak efficiency. Additionally, avoid exceeding recommended load capacities and operating speeds, as this can compromise bearing integrity. By following these guidelines, you can maximize the reliability and lifespan of NTN 6202Z bearings in your application.

2. How do NTN 6202Z bearings compare to other bearing options available in the market?

In a comparative analysis, NTN 6202Z bearings have consistently demonstrated superior durability and performance when compared to alternative bearing options. Their advanced design features, including optimized internal geometry and high-quality steel construction, contribute to reduced friction, minimized wear, and prolonged lifespan. Additionally, NTN 6202Z bearings often offer competitive pricing, making them a preferred choice for discerning engineers and industry professionals seeking reliability and value.

3. What factors contribute to the durability of NTN 6202Z bearings?

Several factors contribute to the durability of NTN 6202Z bearings, including material composition, lubrication methods, environmental conditions, and operational parameters. NTN Corporation employs stringent quality control measures and utilizes premium-grade materials to ensure the integrity and longevity of their bearings. Proper lubrication, maintenance practices, and adherence to operational limits further enhance the durability and performance of NTN 6202Z bearings in demanding applications.

4. Can NTN 6202Z bearings withstand harsh environmental conditions?

Yes, NTN 6202Z bearings are engineered to withstand a wide range of environmental conditions, including temperature variations, humidity, and exposure to contaminants. These bearings feature sealing and shielding mechanisms to protect against ingress of dust, moisture, and other contaminants, ensuring reliable performance even in harsh operating environments. However, proper installation and maintenance are essential to maximize the effectiveness of these protective measures and prolong bearing lifespan.

5. Are NTN 6202Z bearings suitable for high-speed applications?

Yes, NTN 6202Z bearings are designed to accommodate high-speed applications, thanks to their optimized internal geometry, precision manufacturing, and quality materials. These bearings exhibit low friction characteristics, reducing heat generation and enabling smooth operation at elevated speeds. However, it is crucial to consider factors such as load capacity, lubrication, and operating conditions to ensure optimal performance and longevity of NTN 6202Z bearings in high-speed applications.

In conclusion, these FAQs provide valuable insights into NTN 6202Z bearings, addressing common questions about their features, durability, performance, suitability for various applications, and optimization strategies. By understanding the key attributes and considerations associated with NTN 6202Z bearings, engineers and industry professionals can make informed decisions regarding bearing selection, maintenance practices, and application optimization, ultimately maximizing operational efficiency and reliability.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings