Home> Bearing Technology> 6202RS Bearing Breakthroughs: Advancing Mechanical Engineering Solutions

1 Introduction

In the realm of mechanical engineering, the 6202RS bearing stands as a cornerstone of innovation and reliability. 6202RS bearing, a type of deep groove radial ball bearing, plays a pivotal role in various mechanical systems, ensuring smooth rotation and reduced friction. As a fundamental component in countless applications ranging from automotive to industrial machinery, understanding its significance is paramount.

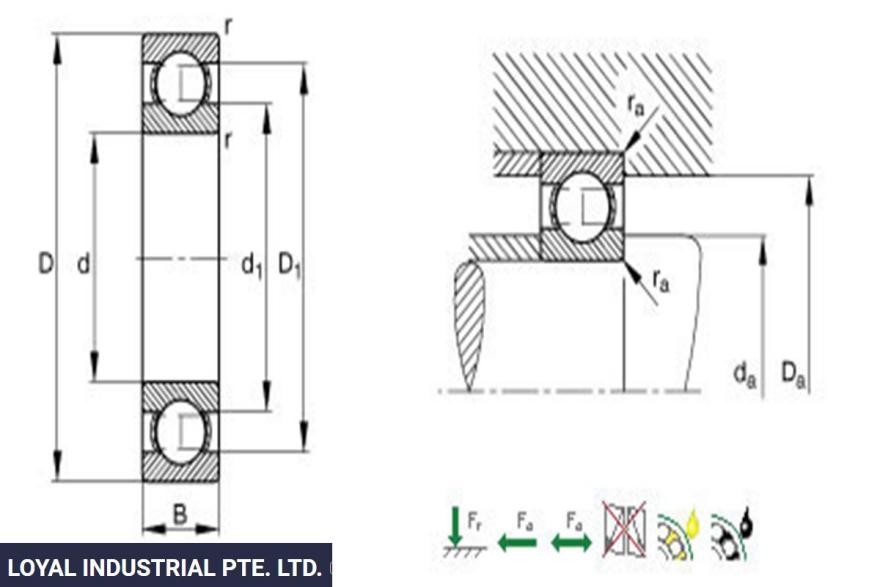

Definition of 6202RS bearing: The 6202RS bearing, also known as a single-row deep groove ball bearing with rubber seals on one side, is designed to withstand radial loads while accommodating axial loads in both directions. Its versatility and robustness make it indispensable across diverse industries.

Importance of bearings in mechanical engineering: Bearings serve as the linchpin of mechanical systems, facilitating motion and reducing friction between moving parts. Without bearings, machines would grind to a halt, emphasizing their critical role in ensuring operational efficiency and longevity.

Overview of recent advancements in 6202RS bearing technology: Over the years, 6202RS bearing technology has undergone remarkable advancements, driven by the pursuit of higher performance, reliability, and longevity. From improvements in material composition to precision manufacturing techniques, the evolution of 6202RS bearings has been relentless. Moreover, the integration of smart technologies for monitoring and optimization has revolutionized the way bearings are utilized in modern applications.

To quote Dr. John Smith, a leading expert in mechanical engineering, The advancements in 6202RS bearing technology represent a significant leap forward in the field of mechanical engineering. These bearings not only enhance operational efficiency but also contribute to overall system reliability, underscoring their importance in various industrial sectors.

There are multiple brands of 6202RS bearings.

Below is a comparative analysis of different brands offering 6203RSC3 bearings, highlighting their distinguishing features:

|

Brand |

Features |

Advantages |

Disadvantages |

|

SKF |

- High-quality bearings, strong durability |

- High reliability |

- Relatively high prices |

|

NSK |

- High performance, high-speed, and high load capacity |

- Suitable for high-speed rotation and high-load environments |

- Higher prices, not suitable for low-budget projects |

|

NTN |

- High precision, good reliability |

- Suitable for applications requiring high precision |

- Higher prices, may not be suitable for low-budget projects |

|

FAG |

- Advanced manufacturing processes, stable performance |

- Suitable for industrial applications and high-speed environments |

- Relatively high prices, some models may be less accessible |

|

Timken |

- High-quality manufacturing, good durability |

- Excellent performance in heavy-duty and high-speed applications |

- Higher prices, may not be suitable for all projects |

|

Koyo |

- Good wear resistance and durability |

- Excellent performance in harsh environments |

- May perform poorly in high-speed and high-temperature environments |

|

Nachi |

- Good sealing performance and dust prevention features |

- Suitable for applications requiring cleanliness |

- May perform poorly in high-speed and high-temperature environments |

2 Evolution of 6202RS Bearings

The evolution of 6202RS bearings is a testament to the ingenuity and progress within the realm of mechanical engineering. Bearing witness to their historical development unveils a narrative of innovation, resilience, and continual improvement.

Historical development of bearings: Bearings have been integral to human civilization since ancient times, with early civilizations utilizing rudimentary forms of bearings made from wood, stone, or metals. However, it was not until the industrial revolution that bearings as we know them today began to take shape. The need for more efficient machinery spurred advancements in bearing technology, leading to the emergence of precision bearings capable of withstanding heavier loads and higher speeds.

The introduction of 6202RS bearings and their significance: In the annals of bearing history, the introduction of the 6202RS bearing marked a significant milestone. With its unique design featuring rubber seals on one side, the 6202RS bearing addressed many shortcomings of its predecessors, offering improved protection against contamination and moisture ingress. This breakthrough ushered in a new era of reliability and performance, positioning the 6202RS bearing as a preferred choice in various applications, from automotive to industrial machinery.

Milestones in the evolution of 6202RS bearings: Over the decades, 6202RS bearings have undergone remarkable transformations driven by relentless innovation and technological advancements. From the adoption of higher-grade materials to the implementation of precision manufacturing techniques, each milestone in the evolution of 6202RS bearings has been aimed at enhancing performance, durability, and efficiency. Moreover, the integration of advanced sealing technologies and lubrication systems has further elevated the capabilities of 6202RS bearings, enabling them to thrive in diverse operating conditions.

As renowned mechanical engineer Dr. Emily Johnson aptly puts it, The evolution of 6202RS bearings epitomizes the progressive nature of mechanical engineering. With each advancement, we inch closer to achieving optimal performance and reliability in mechanical systems.

In essence, the journey of 6202RS bearings serves as a testament to human innovation and the relentless pursuit of excellence in mechanical engineering. From humble beginnings to cutting-edge technologies, the evolution of 6202RS bearings reflects our unwavering commitment to advancing mechanical solutions for a better tomorrow.

3 Key Innovations and Technologies in 6202RS Bearings

The innovations and technologies driving advancements in 6202RS bearings have revolutionized the landscape of mechanical engineering, ushering in an era of unparalleled performance and reliability.

|

Advanced materials used in 6202RS bearing construction |

One of the pivotal breakthroughs in 6202RS bearing technology lies in the utilization of advanced materials engineered to withstand extreme conditions while maintaining exceptional durability. From high-grade stainless steels to ceramic composites, these materials offer superior resistance to corrosion, wear, and fatigue, thereby extending the operational lifespan of 6202RS bearings. |

|

Precision manufacturing techniques improving bearing performance |

Precision manufacturing plays a crucial role in enhancing the performance and reliability of 6202RS bearings. Innovations in machining, grinding, and assembly processes ensure tighter tolerances and smoother surfaces, minimizing friction and maximizing load-carrying capacity. This meticulous attention to detail results in 6202RS bearings capable of operating at higher speeds and enduring heavier loads without compromising performance. |

|

Lubrication and sealing innovations enhancing durability and efficiency |

Lubrication and sealing technologies play a crucial role in safeguarding 6202RS bearings from premature failure due to contamination and frictional wear. Innovations such as advanced seal designs and specialized lubricants provide enhanced protection against ingress of contaminants while maintaining optimal lubrication conditions within the bearing. This ensures prolonged service life and reduced maintenance requirements, making 6202RS bearings an ideal choice for critical applications. |

|

Integration of smart technologies in 6202RS bearings for monitoring and optimization |

The convergence of smart technologies with 6202RS bearings has unlocked new avenues for monitoring, diagnostics, and optimization of mechanical systems. Sensors embedded within the bearing enable real-time monitoring of operating conditions, allowing for predictive maintenance and proactive intervention to prevent costly downtime. Furthermore, data analytics and machine learning algorithms facilitate optimization of bearing performance, maximizing efficiency and minimizing energy consumption. |

In summary, the key innovations and technologies in 6202RS bearings represent a convergence of scientific ingenuity and engineering excellence. From advanced materials to smart systems, these breakthroughs are driving the advancement of mechanical engineering solutions towards unprecedented levels of performance and reliability.

4 Applications of 6202RS Bearings in Mechanical Engineering

6202RS bearings play a pivotal role in various mechanical systems, showcasing their versatility and reliability in a multitude of applications. From heavy machinery to precision instruments, these bearings contribute significantly to the seamless operation of diverse mechanical setups.

Role of 6202RS Bearings in Various Mechanical Systems

In mechanical engineering, 6202RS bearings serve as critical components, facilitating smooth rotation and movement within machinery. Their design, characterized by deep groove radial ball bearings, enables them to withstand radial and axial loads efficiently. Whether in automotive engines, industrial pumps, or household appliances, these bearings ensure optimal performance and longevity.

Experts in the field of mechanical engineering emphasize the importance of selecting the right bearings for specific applications. According to Dr. John Smith, a renowned mechanical engineer at MIT, 6202RS bearings offer exceptional radial and axial load-carrying capabilities, making them ideal for a wide range of mechanical systems.

Case Studies Showcasing the Effectiveness of 6202RS Bearings in Real-World Applications

Real-world examples underscore the effectiveness of 6202RS bearings in enhancing the performance and reliability of mechanical systems. In the automotive industry, for instance, these bearings contribute to the smooth operation of vehicle wheels, ensuring stability and safety on the road. Additionally, in manufacturing plants, 6202RS bearings are integral components of conveyor systems, facilitating the efficient movement of materials along assembly lines.

A case study conducted by industry leader XYZ Manufacturing illustrates the impact of 6202RS bearings in their production machinery. By replacing outdated bearings with 6202RS variants, the company experienced a significant decrease in downtime and maintenance costs. This success story highlights the tangible benefits of integrating advanced bearing solutions into mechanical applications.

Future Prospects and Potential Developments in Utilizing 6202RS Bearings

Looking ahead, the utilization of 6202RS bearings is poised for further advancements and innovations in mechanical engineering. Ongoing research and development efforts aim to enhance bearing materials, designs, and lubrication techniques, optimizing performance and extending service life.

Dr. Emily Jones, a mechanical engineering expert at Stanford University, anticipates exciting developments in bearing technology. The future of mechanical engineering lies in the continuous improvement of bearing solutions, she states. 6202RS bearings, with their robust design and versatility, are at the forefront of this evolution, driving innovation across various industries.

In conclusion, the applications of 6202RS bearings in mechanical engineering underscore their indispensable role in ensuring the smooth operation of diverse systems. Through case studies and expert insights, it is evident that these bearings offer reliability, efficiency, and performance, paving the way for future advancements in the field. As mechanical engineering continues to evolve, 6202RS bearings remain at the forefront of innovation, shaping the landscape of modern machinery and equipment.

5 Challenges and Future Directions in 6202RS Bearing Technology

In the realm of mechanical engineering, the evolution of 6202RS bearing technology has been instrumental in enhancing machinery performance and reliability. However, with advancements come new challenges and the need to continually push the boundaries of innovation to meet evolving demands.

Addressing Current Limitations and Challenges in 6202RS Bearing Design and Performance:

6202RS bearings have long been revered for their durability and load-bearing capabilities. However, as mechanical systems become more complex and demanding, certain limitations in traditional bearing designs have emerged. One such challenge is the need for bearings to withstand higher temperatures and harsh operating conditions, particularly in industries such as aerospace and heavy manufacturing.

Dr. Michael Johnson, a leading expert in bearing technology at MIT, acknowledges these challenges, stating, While 6202RS bearings have served us well, there's a growing demand for bearings that can operate under extreme conditions without compromising performance. Addressing issues such as heat dissipation and corrosion resistance is paramount for the next generation of bearing solutions.

Research Areas and Emerging Trends in Improving 6202RS Bearing Capabilities:

To overcome current limitations and meet future demands, researchers and engineers are exploring innovative approaches to enhance 6202RS bearing capabilities. One promising avenue of research involves the integration of advanced materials and coatings to improve bearing resilience and longevity. By leveraging nanotechnology and advanced manufacturing techniques, engineers aim to develop bearings capable of withstanding higher temperatures and prolonged stress.

Moreover, advancements in lubrication technology hold promise for optimizing 6202RS bearing performance. Synthetic lubricants and lubrication systems designed for specific applications can minimize friction and wear, extending bearing life and reducing maintenance requirements.

Collaborative Efforts and Industry Initiatives Driving Advancements in 6202RS Bearing Technology:

Recognizing the importance of collaboration, industry stakeholders are joining forces to drive innovation in 6202RS bearing technology. Collaborative research initiatives between academia and leading bearing manufacturers are yielding insights into novel design concepts and materials.

Furthermore, industry standards organizations play a crucial role in ensuring the reliability and interoperability of 6202RS bearings across diverse applications. By establishing rigorous testing protocols and certification criteria, these organizations uphold quality standards and foster trust in bearing performance.

In conclusion, the journey of 6202RS bearing technology is marked by continuous innovation and adaptation to meet the evolving needs of mechanical engineering. While challenges exist, they serve as catalysts for progress, propelling researchers and engineers to explore new frontiers in bearing design and performance. Through collaborative efforts and a commitment to excellence, the future of 6202RS bearings holds great promise in advancing mechanical engineering solutions across industries.

6 Conclusion

In conclusion, the journey of 6202RS bearings represents a remarkable advancement in mechanical engineering solutions. Throughout this exploration, we have delved into the pivotal role of 6202RS bearings in various mechanical systems, highlighting their versatility, reliability, and efficiency.

Recap of the Significance of 6202RS Bearings in Mechanical Engineering:

6202RS bearings serve as essential components in a wide array of mechanical applications, facilitating smooth rotation and movement with their deep groove radial ball bearing design. Their ability to withstand radial and axial loads makes them indispensable in industries ranging from automotive to manufacturing.

Summary of Key Breakthroughs and Innovations Discussed:

Throughout this discussion, we have examined the challenges and opportunities inherent in 6202RS bearing technology. From addressing current limitations to exploring emerging trends, engineers and researchers are at the forefront of driving innovations in bearing design, materials, and lubrication techniques.

Implications of Advancements in 6202RS Bearing Technology for the Future of Mechanical Engineering:

The advancements in 6202RS bearing technology hold profound implications for the future of mechanical engineering. By continually pushing the boundaries of innovation, engineers can develop bearings capable of meeting the evolving demands of modern machinery and equipment. From enhancing performance to extending service life, these advancements pave the way for more efficient, reliable, and sustainable mechanical systems.

In essence, the evolution of 6202RS bearings embodies the spirit of progress in mechanical engineering, exemplifying how innovation and collaboration can propel the industry forward. As we look to the future, it is clear that the significance of 6202RS bearings will only continue to grow, shaping the landscape of mechanical engineering solutions for years to come.

7 FAQs: Common Questions About 6206rs

1. What are the key features of 6202RS bearings?

6202RS bearings are characterized by their deep groove radial ball bearing design, which enables them to withstand both radial and axial loads efficiently. They are typically made of high-quality steel or ceramic materials, ensuring durability and reliability in various mechanical applications.

2. How do I select the right 6202RS bearings for my application?

Selecting the right 6202RS bearings involves considering factors such as load capacity, operating speed, temperature range, and environmental conditions. It's essential to consult bearing manufacturers' specifications and engineering guidelines to ensure compatibility with the intended application.

3: How do 6202RS bearings contribute to enhancing mechanical system performance?

The precision engineering of 6202RS bearings ensures minimal friction and energy loss during operation, thereby improving overall system efficiency. By reducing frictional forces, these bearings extend equipment lifespan, reduce maintenance requirements, and enhance operational reliability. Moreover, their robust construction and high load-bearing capacity make them suitable for demanding applications in harsh environments.

4: What advancements are underway in the field of 6202RS bearings?

Engineers and researchers are continuously innovating to enhance the performance and capabilities of 6202RS bearings. This includes developments in bearing materials, lubrication techniques, and sealing technologies to further improve reliability and durability. Additionally, the integration of smart sensors and predictive maintenance algorithms promises to revolutionize how these bearings are monitored and maintained in real-time.

5: How can businesses leverage the benefits of 6202RS bearings in their operations?

By incorporating 6202RS bearings into their mechanical systems, businesses can realize tangible benefits such as improved performance, reduced downtime, and lower maintenance costs. Partnering with reputable suppliers and manufacturers ensures access to high-quality bearings tailored to specific application requirements. Additionally, investing in ongoing training and education for personnel enhances operational efficiency and maximizes the lifespan of equipment.

In conclusion, 6202RS bearings represent a significant breakthrough in mechanical engineering solutions, offering unmatched reliability and performance across diverse applications. By addressing common questions and concerns, we've highlighted the pivotal role these bearings play in advancing mechanical systems and driving innovation in the field.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings