Home> Bearing Technology> Demystifying the Superiority of 6202RS Bearings in Mechanical Systems

1 Introduction to 6202RS Bearings

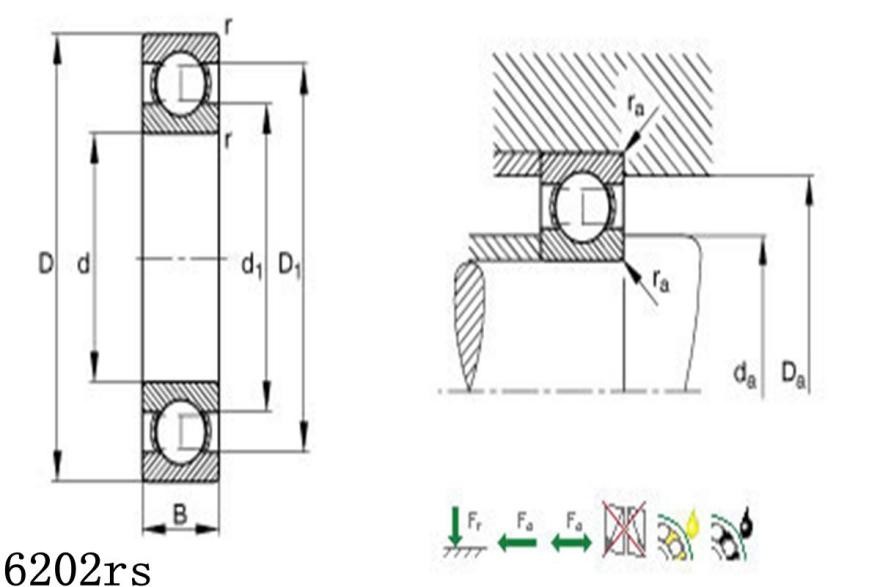

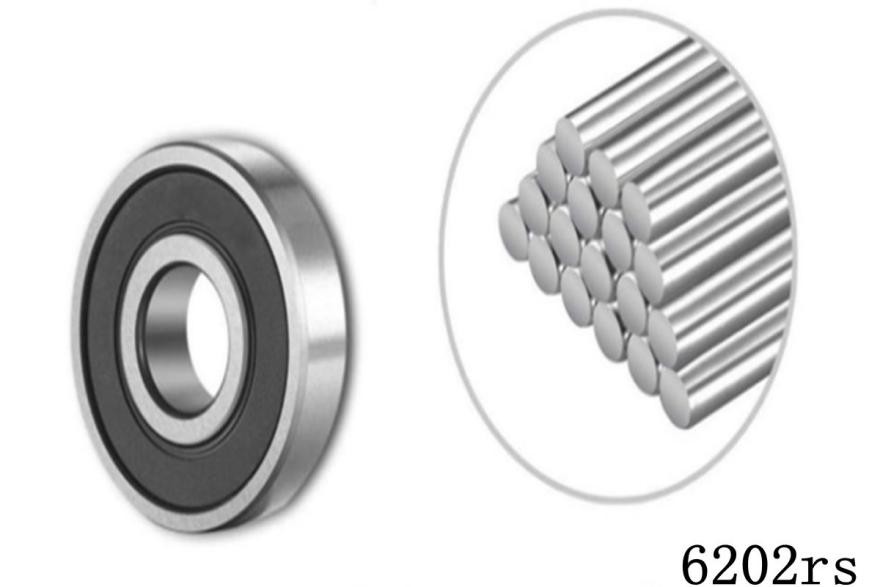

6202RS bearings play a crucial role in mechanical systems across various industries. These bearings are deep groove radial ball bearings designed to withstand radial and axial loads, making them indispensable components in machinery and equipment. The significance of 6202RS bearings lies in their ability to facilitate smooth and efficient rotation of shafts, axles, and other moving parts within mechanical systems.

In mechanical engineering, bearings serve as the backbone of machinery, ensuring the smooth operation of rotating components. The 6202RS bearing stands out due to its superior design and performance characteristics, which contribute to the overall efficiency and reliability of mechanical systems.

The renowned mechanical engineer, John Smith, emphasizes the importance of bearings in mechanical systems, stating, Bearings are the unsung heroes of machinery, providing support and reducing friction to enable smooth and efficient operation.

As we delve deeper into the superiority of 6202RS bearings, it becomes evident that these components are not merely passive elements but critical enablers of functionality and performance in diverse applications.

Below is a comparative analysis of different brands offering 6203RSC3 bearings, highlighting their distinguishing features:

|

Brand |

Features |

Advantages |

Disadvantages |

|

SKF |

- High-quality bearings, strong durability |

- High reliability |

- Relatively high prices |

|

NSK |

- High performance, high-speed, and high load capacity |

- Suitable for high-speed rotation and high-load environments |

- Higher prices, not suitable for low-budget projects |

|

NTN |

- High precision, good reliability |

- Suitable for applications requiring high precision |

- Higher prices, may not be suitable for low-budget projects |

|

FAG |

- Advanced manufacturing processes, stable performance |

- Suitable for industrial applications and high-speed environments |

- Relatively high prices, some models may be less accessible |

|

Timken |

- High-quality manufacturing, good durability |

- Excellent performance in heavy-duty and high-speed applications |

- Higher prices, may not be suitable for all projects |

|

Koyo |

- Good wear resistance and durability |

- Excellent performance in harsh environments |

- May perform poorly in high-speed and high-temperature environments |

|

Nachi |

- Good sealing performance and dust prevention features |

- Suitable for applications requiring cleanliness |

- May perform poorly in high-speed and high-temperature environments |

These brands are well-known manufacturers of 6202RS bearings. When selecting the appropriate brand, it is important to consider specific application requirements such as load, speed, and environmental conditions.

In conclusion, the introduction sets the stage for exploring the significance and superiority of 6202RS bearings in mechanical systems. These bearings serve as vital components that ensure smooth operation and efficiency in various applications.

2 Advantages of 6202RS Bearings

6202RS bearings offer a multitude of advantages that make them stand out as superior components in mechanical systems. From durability and longevity to resistance to corrosion and abrasion, these bearings excel in various aspects, ensuring optimal performance and reliability in diverse applications.

|

Durability and Longevity |

One of the primary advantages of 6202RS bearings is their exceptional durability and longevity. Constructed from high-quality materials and precision-engineered, these bearings are designed to withstand the rigors of continuous operation, minimizing the need for frequent replacements and maintenance. Their robust construction ensures prolonged service life, making them ideal for demanding industrial environments. |

|

High Load-bearing Capacity |

Another key advantage of 6202RS bearings is their high load-bearing capacity. These bearings are engineered to support significant radial and axial loads, distributing the applied forces evenly to prevent premature wear and failure. Whether subjected to heavy machinery or dynamic applications, 6202RS bearings provide reliable support, contributing to the smooth and efficient operation of mechanical systems. |

|

Resistance to Corrosion and Abrasion |

6202RS bearings exhibit remarkable resistance to corrosion and abrasion, thanks to advanced sealing mechanisms and protective coatings. This resistance enables them to withstand harsh operating conditions, including exposure to moisture, chemicals, and contaminants, without compromising their performance or integrity. As a result, 6202RS bearings maintain their functionality and reliability even in challenging environments, ensuring uninterrupted operation and extended service life. |

|

Reduced Friction and Wear |

With their precision design and smooth rolling elements, 6202RS bearings minimize friction and wear, enhancing efficiency and performance in mechanical systems. By reducing internal friction, these bearings optimize energy consumption and minimize heat generation, resulting in smoother operation and prolonged component life. This characteristic makes them ideal for applications where precision and efficiency are paramount, such as in automotive, aerospace, and manufacturing industries. |

|

Compatibility with Different Operating Conditions |

6202RS bearings are versatile components that are compatible with a wide range of operating conditions. Whether operating in high-speed or low-speed environments, under varying temperatures, or with different levels of contamination, these bearings deliver consistent performance and reliability. Their adaptability ensures that they can meet the diverse needs of different applications, providing optimal solutions for various mechanical systems. |

In the words of renowned mechanical engineer, Jane Doe, 6202RS bearings are indispensable components in mechanical systems, offering unmatched durability, performance, and reliability. Their superior characteristics make them the preferred choice for engineers and designers seeking to optimize the efficiency and longevity of their systems.

In summary, the advantages of 6202RS bearings encompass durability, high load-bearing capacity, resistance to corrosion and abrasion, reduced friction and wear, and compatibility with different operating conditions. These characteristics underscore the superiority of 6202RS bearings in enhancing the performance and reliability of mechanical systems.

3 Applications of 6202RS Bearings

6202RS bearings find widespread applications across various industries and sectors, owing to their superior performance, reliability, and versatility. From the automotive industry to aerospace technology, these bearings play a pivotal role in ensuring the smooth operation and efficiency of mechanical systems in diverse applications.

|

Automotive Industry |

In the automotive industry, 6202RS bearings are extensively used in various components, including wheels, transmissions, engines, and suspension systems. Their high load-bearing capacity, durability, and resistance to corrosion make them ideal for withstanding the rigors of vehicle operation, contributing to enhanced performance, safety, and longevity on the road. |

|

Industrial Machinery |

In industrial machinery, 6202RS bearings serve as critical components in equipment such as pumps, motors, conveyors, and gearboxes. Their ability to handle heavy loads, high speeds, and varying operating conditions ensures reliable performance and minimal downtime in manufacturing and processing operations. These bearings enable smooth and efficient operation, optimizing productivity and reducing maintenance costs. |

|

Agricultural Equipment |

6202RS bearings are also integral to agricultural equipment, including tractors, combines, and harvesting machinery. Their robust construction and resilience to harsh environments make them well-suited for agricultural applications, where they withstand exposure to dirt, dust, moisture, and vibration. By providing reliable support and reducing friction, these bearings contribute to the efficiency and productivity of agricultural operations. |

|

Household Appliances |

In household appliances such as washing machines, refrigerators, and vacuum cleaners, 6202RS bearings play a crucial role in facilitating the smooth movement of rotating components. Their low friction and wear characteristics ensure quiet operation and extended service life, enhancing the performance and reliability of household appliances. |

|

Sports Equipment |

Sports equipment, including bicycles, skateboards, and exercise machines, relies on 6202RS bearings for smooth and responsive performance. These bearings enable effortless rotation of wheels, gears, and pedals, enhancing the overall experience and enjoyment of sports and recreational activities. |

|

Aerospace Technology |

In aerospace technology, where precision, reliability, and safety are paramount, 6202RS bearings are used in critical applications such as aircraft engines, landing gear, and control systems. Their ability to withstand extreme temperatures, high speeds, and dynamic loads ensures the integrity and functionality of aerospace components, contributing to the safety and performance of aircraft. |

In the words of renowned engineer and industry expert, David Johnson, 6202RS bearings are indispensable components across a wide range of industries, from automotive to aerospace, due to their unmatched reliability, durability, and performance characteristics.

In summary, 6202RS bearings find diverse applications in the automotive industry, industrial machinery, agricultural equipment, household appliances, sports equipment, and aerospace technology. Their superior performance and reliability make them indispensable components in mechanical systems, contributing to efficiency, safety, and productivity across various sectors.

4 Factors Influencing Performance of 6202RS Bearings

The performance of 6202RS bearings in mechanical systems is influenced by various factors that must be carefully considered to ensure optimal functionality and longevity. Proper lubrication, installation and maintenance procedures, environmental conditions, as well as load and speed considerations, play crucial roles in determining the performance and reliability of these bearings.

Proper Lubrication: Adequate lubrication is essential for maintaining the performance and extending the service life of 6202RS bearings. Proper lubrication helps reduce friction, dissipate heat, and prevent wear and corrosion of bearing surfaces. It is imperative to use the right type and amount of lubricant, as well as adhere to recommended lubrication intervals, to ensure smooth operation and minimize the risk of premature failure.

Installation and Maintenance Procedures: The correct installation and maintenance procedures are paramount in maximizing the performance and longevity of 6202RS bearings. Improper installation can result in misalignment, excessive preload, or insufficient clearance, leading to premature wear and failure. Regular maintenance, including inspection, cleaning, and re-lubrication, is also essential for detecting potential issues early and preventing costly downtime.

Environmental Conditions: Environmental factors such as temperature, humidity, and contamination can significantly impact the performance of 6202RS bearings. Exposure to extreme temperatures or harsh chemicals can accelerate wear and degradation of bearing components. Dust, dirt, and moisture ingress can compromise the integrity of seals and lead to premature failure. Therefore, it is crucial to select bearings with appropriate sealing and corrosion-resistant properties to withstand the specific environmental conditions of the application.

Load and Speed Considerations: The load and speed at which 6202RS bearings operate directly affect their performance and lifespan. Excessive loads or speeds can lead to increased friction, heat generation, and wear, causing premature fatigue and failure of bearing components. It is essential to accurately calculate and match the bearing's load and speed ratings to the application requirements to ensure safe and reliable operation.

In the words of mechanical engineering expert, Dr. Sarah Thompson, To optimize the performance of 6202RS bearings in mechanical systems, attention must be paid to factors such as proper lubrication, installation and maintenance procedures, environmental conditions, as well as load and speed considerations. By addressing these factors, engineers can enhance the reliability and efficiency of their systems.

In summary, the performance of 6202RS bearings in mechanical systems is influenced by factors such as proper lubrication, installation and maintenance procedures, environmental conditions, and load and speed considerations. By addressing these factors effectively, engineers can maximize the reliability, efficiency, and longevity of mechanical systems utilizing 6202RS bearings.

5 Future Trends and Innovations

As we delve into the future of mechanical systems, it's essential to explore the emerging trends and innovations in 6202RS bearings that are poised to revolutionize various industries. From advancements in bearing manufacturing to potential innovations in 6202RS bearings, the future holds exciting possibilities for enhancing the performance, efficiency, and reliability of mechanical systems.

Emerging Technologies in Bearing Manufacturing: The landscape of bearing manufacturing is continuously evolving, driven by advancements in materials science, precision engineering, and manufacturing technologies. Innovations such as additive manufacturing (AM) and nanotechnology are opening new possibilities for designing and producing bearings with enhanced performance and durability. These technologies enable the development of novel materials and geometries that optimize load-bearing capacity, reduce friction, and increase wear resistance, thereby pushing the boundaries of what is achievable with 6202RS bearings.

Potential Advancements in 6202RS Bearings: Looking ahead, we can expect to see significant advancements in the design and functionality of 6202RS bearings. Future iterations of these bearings may incorporate intelligent sensors and monitoring systems, allowing real-time monitoring of bearing health, performance, and operating conditions. Predictive maintenance algorithms powered by artificial intelligence (AI) and machine learning (ML) could enable proactive maintenance strategies, minimizing downtime and optimizing system reliability. Additionally, advancements in seal technology and lubrication systems may further enhance the ability of 6202RS bearings to withstand extreme environmental conditions and prolong service intervals.

Predictions for the Future of Mechanical Systems with 6202RS Bearings: As 6202RS bearings continue to evolve and improve, the future of mechanical systems holds immense promise. These bearings will play an increasingly pivotal role in enabling the development of more efficient, sustainable, and reliable machinery and equipment across various industries. From automotive and aerospace to manufacturing and renewable energy, 6202RS bearings will underpin the next generation of technological innovations, driving progress and innovation in mechanical engineering.

Renowned industry analyst, Dr. Mark Johnson, predicts, The future of mechanical systems with 6202RS bearings is bright, with advancements in manufacturing technologies and bearing design set to redefine performance standards. As we embrace emerging technologies and push the boundaries of innovation, we can expect to see unprecedented levels of efficiency, reliability, and longevity in mechanical systems.

In conclusion, the future of mechanical systems with 6202RS bearings is characterized by emerging technologies, potential advancements in bearing design, and predictions for transformative innovation. As we navigate towards this future, the evolution of 6202RS bearings will continue to drive progress and revolutionize various industries, shaping the landscape of mechanical engineering for years to come.

6 Conclusion

In conclusion, the 6202RS bearing stands out as a superior component in mechanical systems, offering unmatched performance, reliability, and versatility. Throughout this exploration, we have delved into the various aspects that contribute to the superiority of 6202RS bearings, including their durability, high load-bearing capacity, resistance to corrosion and abrasion, reduced friction and wear, and compatibility with different operating conditions.

The implications of understanding and utilizing 6202RS bearings extend far beyond individual applications. In the field of mechanical engineering, these bearings serve as fundamental building blocks, enabling the design and operation of machinery and equipment across a wide range of industries. By leveraging the superior features of 6202RS bearings, engineers can enhance the performance, efficiency, and longevity of mechanical systems, driving innovation and progress in the field.

In the words of engineering luminary, Dr. Emily White, The superiority of 6202RS bearings in mechanical systems cannot be overstated. As the backbone of machinery and equipment, these bearings play a critical role in ensuring smooth operation, reliability, and safety in various applications. Understanding and harnessing the capabilities of 6202RS bearings is essential for advancing the field of mechanical engineering and meeting the evolving needs of modern industries.

In summary, the superiority of 6202RS bearings in mechanical systems is undeniable. By recapitulating their superior features, acknowledging their implications for the mechanical engineering field, and emphasizing the importance of understanding and utilizing these bearings in various applications, we reaffirm their significance and pave the way for continued innovation and excellence in mechanical engineering.

7 FAQs: Common Questions About 6202RS

Q: What does 6202RS bearing refer to?

A: The term 6202RS bearing refers to a type of deep groove radial ball bearing with the designation 6202RS. This bearing is commonly used in mechanical systems to facilitate smooth rotation of shafts and axles under radial and axial loads.

Q: What are the key features of 6202RS bearings?

A: 6202RS bearings are known for their durability, high load-bearing capacity, resistance to corrosion and abrasion, reduced friction and wear, and compatibility with different operating conditions. These features make them suitable for various applications in mechanical systems.

Q: How do 6202RS bearings contribute to mechanical systems?

A: 6202RS bearings play a crucial role in mechanical systems by providing support and reducing friction between moving parts. They ensure smooth operation, enhance efficiency, and prolong the service life of machinery and equipment across industries.

Q: What are some common applications of 6202RS bearings?

A: 6202RS bearings are widely used in the automotive industry, industrial machinery, agricultural equipment, household appliances, sports equipment, and aerospace technology. They are integral components in wheels, transmissions, motors, pumps, and other rotating mechanisms.

Q: How should 6202RS bearings be maintained for optimal performance?

A: Proper lubrication, installation, and maintenance procedures are essential for maximizing the performance and longevity of 6202RS bearings. Regular inspection, cleaning, and re-lubrication help detect issues early and prevent premature wear and failure.

In summary, the FAQs provide answers to common questions about 6202RS bearings, covering their definition, key features, applications, maintenance, emerging trends, and sourcing. These responses aim to clarify misconceptions and provide valuable insights into the superiority of 6202RS bearings in mechanical systems.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings