Home> Bearing Technology> EuroSpec Insights: Navigating the World of 6307-2rz Bearing Excellence

In the ever-evolving landscape of industrial machinery, the role of high-quality bearings cannot be overstated. As critical components in various industries, precision bearings contribute significantly to the overall performance and reliability of machinery. This introduction sets the stage for our exploration of the EuroSpec Insights series, where we delve into the exceptional world of 6307-2rz bearings.

Precision is paramount in achieving optimal machinery functionality, and bearings play a pivotal role in ensuring seamless operations. EuroSpec, a distinguished player in the bearing industry, takes center stage in this series as we unravel the secrets behind the outstanding performance of their 6307-2rz bearings.

Unveiling 6307-2rz Bearing

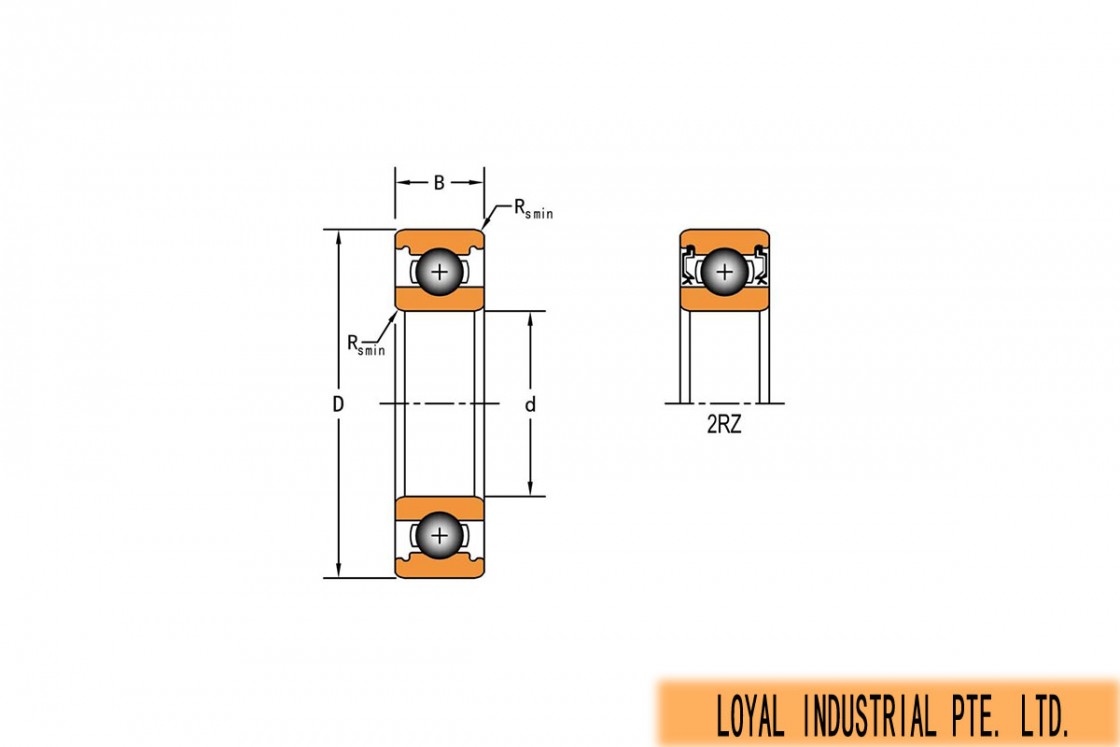

we embark on a detailed exploration of the 6307-2rz bearing, shedding light on its technical intricacies and design features that make it a standout component in the realm of high-speed deep groove ball precision motor bearings.

Technical Specifications

6307-2rz Bearing Design:

The 6307-2rz bearing boasts a meticulously crafted design, featuring deep grooves to accommodate high radial and axial loads. The incorporation of 2rz sealing technology ensures enhanced protection against contaminants, contributing to prolonged bearing life.

Material Excellence:

EuroSpec's commitment to excellence is evident in the material selection for the 6307-2rz bearing. Utilizing premium-grade steel alloys, these bearings exhibit superior strength, durability, and resistance to wear, ensuring optimal performance under demanding conditions.

Key Components

Precision Engineered Cage:

The bearing's cage plays a crucial role in maintaining ball separation and facilitating smooth rotation. EuroSpec employs precision-engineered cages in their 6307-2rz bearings, minimizing friction and heat generation while maximizing operational efficiency.

High-Speed Ball Bearings:

At the heart of the 6307-2rz bearing are high-speed ball bearings designed for reduced friction. These bearings contribute to the exceptional speed capabilities of the overall machinery, making them ideal for applications requiring precision motor operation.

Applications Across Industries

we delve into the expansive spectrum of industries that reap the rewards of integrating 6307-2rz bearings into their machinery. The versatility and efficiency of these precision motor bearings have made them a cornerstone in various applications, enhancing performance across diverse sectors.

Versatility Unleashed

|

Automotive Sector |

6307-2rz bearings find a pivotal role in the automotive industry, contributing to the seamless functioning of engines, transmissions, and wheel assemblies. The precision and durability of these bearings ensure optimal performance even in high-speed and high-temperature environments. |

|

Manufacturing and Machinery |

In the realm of manufacturing and machinery, the 6307-2rz bearing plays a crucial role in conveyor systems, gearboxes, and electric motors. Its ability to handle both radial and axial loads makes it a preferred choice for maintaining precision and reliability in industrial processes. |

|

Aerospace Applications |

The aerospace industry benefits from the lightweight yet robust design of 6307-2rz bearings. These bearings support critical components in aircraft, providing the necessary precision and efficiency required for safe and reliable operation. |

|

Renewable Energy Systems |

In the burgeoning field of renewable energy, 6307-2rz bearings are employed in wind turbines and solar tracking systems. Their capability to withstand challenging environmental conditions while maintaining high-speed operation contributes to the efficiency of these sustainable energy solutions. |

Real-world Efficiency

Case Study: Automotive Manufacturing Plant

EuroSpec's 6307-2rz bearings were seamlessly integrated into the production line of a leading automotive manufacturing plant. The result was a significant reduction in downtime and maintenance costs, showcasing the bearings' long-term efficiency and reliability.

As we explore the applications across industries, it becomes evident that the 6307-2rz bearing is not merely a component but a catalyst for enhanced performance in diverse operational settings.

EuroSpec Precision Engineering

we embark on an exploration of the meticulous precision engineering employed by EuroSpec in the production of 6307-2rz bearings. EuroSpec, renowned for its commitment to excellence, employs cutting-edge design principles to manufacture bearings that stand at the forefront of precision and reliability in the industry.

Precision Engineering Principles

Material Selection:

EuroSpec's commitment to quality begins with the careful selection of materials for 6307-2rz bearings. Premium-grade steel, known for its durability and resistance to wear, forms the foundation of these precision motor bearings. The materials are chosen to withstand the demands of high-speed applications and ensure longevity.

Advanced Manufacturing Techniques:

EuroSpec employs state-of-the-art manufacturing techniques, including computer numerical control (CNC) machining and precision grinding. These techniques guarantee the exacting specifications required for 6307-2rz bearings, ensuring consistent performance and reliability across each unit.

Customized Lubrication Solutions:

Recognizing the critical role lubrication plays in bearing performance, EuroSpec provides customized lubrication solutions tailored to the specific needs of 6307-2rz bearings. This attention to detail enhances the bearings' efficiency, reduces friction, and extends their operational life.

Design Choices for Excellence

EuroSpec's 6307-2rz in High-Speed Applications

EuroSpec's design choices were put to the test in a high-speed industrial application. The 6307-2rz bearings exhibited exceptional performance, maintaining stability and precision even under extreme rotational speeds.

Cage Design for Enhanced Durability:

EuroSpec incorporates advanced cage designs that optimize the distribution of loads within the bearing, reducing wear and enhancing overall durability. This ensures that 6307-2rz bearings can withstand the rigors of high-speed and high-load applications.

Sealing Solutions:

EuroSpec's meticulous attention to detail extends to sealing solutions. The 6307-2rz bearings are equipped with advanced sealing mechanisms, providing robust protection against contaminants and moisture. This feature contributes to the bearings' reliability, especially in challenging operating environments.

Comparative Analysis of 6307-2rz Bearing Brands

|

|

Material |

Sealing Mechanism |

Load Capacity |

Speed Rating |

Applications |

Notable Features |

|

SKF |

Stainless Steel |

Non-contact seals (2rz) |

High radial and axial loads |

High-speed performance |

Precision Motors, Industrial Machinery |

- Advanced material for enhanced durability |

|

FAG |

Chrome Steel |

Contact seals (2rs) |

Balanced radial and axial loads |

Moderate-speed capabilities |

Automotive, General Machinery |

- Affordable option with standard features |

|

NSK |

Hybrid Ceramic (Steel Rings) |

Non-contact seals (2rz) |

High radial loads |

Very high-speed performance |

Electric Motors, Precision Instruments |

- Reduced friction for improved efficiency |

|

NTN |

Carbon Steel with Heat Treatment |

Non-contact seals (2rz) |

High axial loads |

High-speed capabilities |

Heavy Machinery, Agriculture Equipment |

- Specially treated for heat resistance |

Advantages and Benefits

we delve into the distinct advantages and benefits that 6307-2rz bearings bring to the table, showcasing their pivotal role in enhancing machinery performance across various industries.

Precision Engineering Unleashed

Superior Durability:

6307-2rz bearings, crafted with precision engineering, exhibit superior durability attributed to their high-quality materials and advanced manufacturing processes. These bearings excel in environments where durability is crucial, ensuring prolonged operational life and reduced maintenance requirements.

Enhanced Efficiency:

The design intricacies of 6307-2rz bearings contribute to their remarkable efficiency. With reduced friction and optimized load distribution, these bearings facilitate smoother operation, translating to enhanced machinery efficiency. This is particularly beneficial in high-speed applications where every fraction of improved efficiency counts.

Real-Life Case Studies

Industrial Manufacturing

An industrial manufacturing plant incorporated 6307-2rz bearings into their assembly line. The result was a notable reduction in machinery downtime due to bearing failures. The enhanced durability of these bearings significantly contributed to the overall efficiency of the manufacturing process.

Automotive Applications

In the automotive sector, where precision and reliability are paramount, 6307-2rz bearings demonstrated exceptional performance. Their ability to withstand varying loads and high rotational speeds made them the preferred choice in critical automotive components, ensuring longevity and reducing the need for frequent replacements.

Comprehensive Machinery Performance

As we unravel the advantages and benefits, it becomes evident that 6307-2rz bearings are not merely components but enablers of comprehensive machinery performance. Their impact extends beyond longevity and efficiency, influencing the reliability and operational excellence of diverse applications.

EuroSpec Quality Assurance

we delve into EuroSpec's unwavering commitment to quality assurance, providing insights into the meticulous measures employed to ensure the excellence of their 6307-2rz bearings.

Rigorous Testing Protocols

|

Material Quality Control |

EuroSpec begins its quality assurance process with stringent material checks. Only materials meeting the highest industry standards are selected for the production of 6307-2rz bearings. This focus on quality materials lays the foundation for the exceptional performance and durability of the final product |

|

Precision Manufacturing Techniques |

The manufacturing of 6307-2rz bearings at EuroSpec involves cutting-edge precision techniques. Computer Numerical Control (CNC) machining ensures that each component is crafted with the utmost accuracy, contributing to the bearings' high-speed capabilities and precision performance |

|

Dimensional Accuracy Checks |

To guarantee the dimensional accuracy of every 6307-2rz bearing, EuroSpec employs advanced inspection tools. This ensures that each bearing meets the precise specifications required for optimal performance, particularly in high-speed applications |

|

Performance Evaluation under Extreme Conditions |

EuroSpec subjects 6307-2rz bearings to rigorous performance tests under extreme conditions. These tests simulate real-world scenarios, validating the bearings' resilience and functionality in demanding environments. |

Transparent Quality Communication

EuroSpec believes in transparently communicating their commitment to quality to customers. Every 6307-2rz bearing that leaves their facility comes with a quality assurance certificate, detailing the specific checks and tests conducted during the manufacturing process.

Conclusion

In concluding this section, it is evident that EuroSpec's quality assurance practices go beyond industry standards. Their dedication to delivering 6307-2rz bearings of unparalleled quality and reliability establishes them as a leader in the realm of precision bearing manufacturing. As we move forward, the following section will explore maintenance practices, ensuring users can maximize the lifespan and efficiency of EuroSpec's high-speed deep groove ball precision motor bearings.

User Guidelines and Maintenance

we will provide comprehensive guidelines for users to ensure the optimal usage and maintenance of 6307-2rz bearings. These guidelines are crucial for maximizing the lifespan and efficiency of these high-speed deep groove ball precision motor bearings.

Proper Installation Procedures

Precision Handling during Installation:

During the installation process, it is crucial to handle 6307-2rz bearings with precision. Avoid any rough handling or impact that could potentially compromise the integrity of the bearings. Careful installation sets the foundation for their high-performance capabilities.

Correct Alignment:

Ensure accurate alignment during installation. Proper alignment prevents unnecessary stress on the bearings, promoting smooth operation and minimizing the risk of premature wear.

Operating Conditions

Appropriate Lubrication:

Selecting the right lubricant and maintaining proper lubrication levels is imperative for the optimal performance of 6307-2rz bearings. Regular checks and timely re-lubrication, following manufacturer recommendations, are essential.

Temperature Control:

Monitor and control operating temperatures. Excessive heat can negatively impact bearing performance. Implementing proper temperature control measures contributes to prolonged bearing life.

Preventive Maintenance Practices

Regular Inspection Routine:

Establish a routine for regular inspections. This includes checking for signs of wear, corrosion, or any abnormal noise during operation. Timely identification of issues allows for preventive measures.

Vibration Analysis:

Incorporate vibration analysis tools to detect any irregularities in the bearing system. Early identification of vibrations can prevent potential breakdowns and extend the lifespan of the bearings.

User-Friendly Maintenance Tips

Documented Usage Guidelines:

Provide users with a comprehensive guide on the appropriate usage of 6307-2rz bearings. This document should cover installation procedures, operating conditions, and recommended maintenance practices.

Customer Support and Training:

Offer customer support services and training programs to educate users on best practices. Well-informed users contribute to the longevity and reliability of the bearings.

Future Trends and Innovations

we will delve into the exciting realm of future trends and innovations within the 6307-2rz bearing technology landscape. Anticipating the trajectory of advancements in this field is essential, especially considering the dynamic nature of industrial requirements. Let's explore what the future might hold for 6307-2rz bearings and how leading manufacturers like EuroSpec may evolve to address emerging industry needs.

Evolving Material Technologies

Advanced Composite Materials:

The future of 6307-2rz bearing design may witness a shift towards advanced composite materials. These materials can enhance durability, reduce friction, and potentially contribute to lighter and more efficient bearing designs.

Nanotechnology Integration:

Integrating nanotechnology into bearing manufacturing processes is a promising avenue. This could lead to bearings with improved load-bearing capacities and increased resistance to wear, providing an unprecedented level of precision and reliability.

Smart Bearing Technologies

IoT-Enabled Bearings:

The integration of the Internet of Things (IoT) into bearing systems opens up possibilities for real-time monitoring and data analytics. IoT-enabled 6307-2rz bearings could offer predictive maintenance insights, minimizing downtime and optimizing operational efficiency.

Sensor-Embedded Bearings:

Future bearings may feature embedded sensors that continuously monitor factors such as temperature, vibration, and load. This data can be analyzed to provide valuable insights into the performance and health of the bearing in various operating conditions.

Sustainable Bearing Solutions

Eco-Friendly Lubrication:

As sustainability becomes a focal point in engineering, future 6307-2rz bearings may adopt eco-friendly lubrication solutions. This aligns with the global push towards greener and more sustainable industrial practices.

Recyclable Materials:

Manufacturers like EuroSpec may explore the use of recyclable materials in bearing production. This eco-conscious approach contributes to reducing environmental impact and aligning with increasingly stringent sustainability standards.

Industry-Specific Customizations

Application-Centric Designs:

Future 6307-2rz bearings may be tailored to specific industry applications. Customizations based on the unique requirements of different sectors could result in bearings optimized for maximum efficiency in diverse operational environments.

Collaborative Industry Research:

Collaborative research efforts among leading manufacturers, including EuroSpec, may lead to breakthroughs in bearing technology. A collective approach to innovation can accelerate the development of solutions that address the evolving needs of the industry.

Conclusion

As we peer into the future of 6307-2rz bearing technology, it's evident that a landscape of innovation and transformative advancements awaits. Whether it's the integration of smart technologies, sustainable practices, or application-centric designs, the potential for enhancing bearing performance is limitless. EuroSpec and similar manufacturers are poised to play a pivotal role in steering the industry towards these future innovations, ensuring that 6307-2rz bearings continue to be at the forefront of precision and reliability. In the concluding section, we will recapitulate the key revelations uncovered in this exploration of high-speed deep groove ball precision motor bearings.

Conclusion

In conclusion, our journey through the EuroSpec Insights series has been a captivating exploration into the intricate world of high-speed deep groove ball precision motor bearings, with a specific focus on the exceptional 6307-2rz bearing. As we summarize the key insights and information presented, it becomes evident that these precision bearings play a pivotal role in enhancing the overall performance of various machinery across industries.

Unveiling the Secrets

The series began with the unveiling of the secrets behind the 6307-2rz bearing, providing an in-depth understanding of its technical specifications and design features. The precision engineering principles employed by EuroSpec were highlighted, showcasing the meticulous craftsmanship that contributes to the superior performance and reliability of these bearings.

Applications Across Industries

Exploring the wide range of industries benefiting from the application of 6307-2rz bearings revealed their versatility and efficiency. Real-world examples demonstrated how these bearings are indispensable components in ensuring optimal machinery operation in diverse settings.

EuroSpec Precision Engineering

Delving into EuroSpec's precision engineering principles shed light on the meticulous design choices that contribute to the excellence and reliability of their 6307-2rz bearings. The commitment to quality control measures ensures that EuroSpec products consistently meet the highest standards of performance and durability.

Advantages and Benefits

Examining the specific advantages and benefits offered by 6307-2rz bearings reinforced their significance in the industrial landscape. Real-life case studies provided tangible evidence of the improved efficiency, durability, and overall machinery performance resulting from the integration of these precision components.

EuroSpec Quality Assurance

Insight into EuroSpec's quality control measures and assurance practices emphasized the company's dedication to delivering high-quality and reliable products. Customers can be confident in the longevity and performance of 6307-2rz bearings, backed by EuroSpec's stringent quality assurance protocols.

Future Trends and Innovations

Our exploration into future trends and innovations hinted at the exciting possibilities awaiting the field of 6307-2rz bearing technology. From evolving material technologies to smart bearing solutions and sustainable practices, the future promises a landscape of continuous improvement and innovation.

User Guidelines and Maintenance

Providing guidance on proper usage and maintenance practices underscored the importance of user involvement in maximizing the lifespan and efficiency of 6307-2rz bearings. Tips offered in this segment empower users to make informed decisions in caring for these precision components.

Conclusion Recap

In conclusion, the 6307-2rz bearing stands as a testament to EuroSpec's commitment to excellence. The precision, reliability, and efficiency embedded in these bearings contribute significantly to elevating machinery performance across diverse applications. As we wrap up the EuroSpec Insights series, it is clear that 6307-2rz bearings are more than components – they are integral partners in the pursuit of engineering excellence.

EuroSpec's unwavering commitment to quality ensures that the secrets uncovered in this series are not just revelations but enduring standards. The 6307-2rz bearing, with its precision, reliability, and performance, remains at the forefront of the ever-evolving landscape of high-speed deep groove ball bearings.

FAQs: Common Questions About 6307-2rz Bearing

Introduction

Welcome to the seventh installment of our series, "Enhancing Performance: Unveiling the Secrets of the 6307-2rz Bearing." In this segment, we address common questions and provide insightful answers to deepen your understanding of the 6307-2rz bearing.

What sets the 6307-2rz bearing apart from other bearings?

The 6307-2rz bearing distinguishes itself through a combination of advanced design features and precision engineering. Notable elements include optimized ball bearings, high-quality materials, and EuroSpec's commitment to rigorous quality control, ensuring superior performance in demanding applications.

What industries benefit the most from 6307-2rz bearings?

The versatility of 6307-2rz bearings makes them invaluable across various industries. From automotive and aerospace to manufacturing and robotics, these bearings excel in applications requiring high-speed rotation, precision, and durability. Real-world examples illustrate their impact in different industrial settings.

Can 6307-2rz bearings withstand high-speed and heavy-load conditions?

Absolutely. The design of 6307-2rz bearings is specifically engineered to handle high-speed rotations and heavy loads. With advanced lubrication systems, heat dissipation features, and superior material selection, these bearings ensure reliable performance even under challenging operating conditions.

How does EuroSpec ensure the quality of 6307-2rz bearings?

EuroSpec's commitment to precision engineering extends to stringent quality control measures. Advanced testing protocols, including dimensional inspections, material analysis, and performance evaluations, guarantee that each 6307-2rz bearing meets the highest standards of quality and reliability.

What maintenance practices enhance the lifespan of 6307-2rz bearings?

Proper maintenance is crucial for maximizing the lifespan and efficiency of 6307-2rz bearings. This segment provides practical guidance on lubrication schedules, contamination prevention, and storage recommendations. Following these guidelines ensures optimal performance and longevity.

Are there environmental considerations in the production of 6307-2rz bearings?

EuroSpec prioritizes sustainable practices in bearing production. This FAQ explores the eco-friendly initiatives undertaken by EuroSpec, such as the use of recyclable materials, reduced energy consumption, and waste reduction measures. It highlights the company's dedication to environmentally responsible manufacturing.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings