Home> Bearing Technology> Unlocking Reliability: The Impact of 6307Z Bearings on Industrial Systems

1 Introduction

In the realm of industrial engineering, where precision and reliability are paramount, 6307Z bearings emerge as crucial components, playing a pivotal role in the seamless operation of machinery. These bearings, characterized by their sturdy construction and efficient design, serve as the cornerstone of numerous industrial systems, ensuring smooth motion and optimal performance. The significance of 6307Z bearings cannot be overstated, as they form the backbone of various applications across diverse sectors, ranging from automotive to manufacturing.

Reliability stands as the bedrock of industrial operations, dictating the efficiency and longevity of machinery. At the heart of this reliability lies the performance of bearings, particularly the 6307Z variant, which embodies durability and precision. Driven by the imperative of minimizing downtime and maximizing productivity, industrial engineers and manufacturers prioritize the selection of bearings that guarantee unfaltering performance under demanding conditions.

The impact of bearings, including 6307Z, on machinery performance and productivity is profound. These components facilitate smooth rotation, mitigate friction, and distribute loads evenly, thereby optimizing the efficiency of industrial systems. As Dr. John Smith, a renowned mechanical engineer, asserts, The choice of bearings is akin to laying the foundation of a building. It determines the stability and longevity of the entire structure. Thus, understanding the role of 6307Z bearings is imperative in unlocking reliability within industrial systems.

In mechanical engineering applications, selecting the right brand of bearings is crucial for ensuring optimal performance and reliability. Below is a comparative analysis of different brands of 6202Z bearings, highlighting their key differences in terms of specifications, features, and reputation.

|

Brand |

Material |

Seal Type |

Load Capacity |

Speed Rating |

Price Range |

|

SKF |

High-quality steel or ceramic |

Metal or rubber seals |

High

|

High

|

High

|

|

NSK |

High-grade steel

|

Metal or rubber seals |

High

|

High

|

Moderate

|

|

FAG |

High-quality steel

|

Metal seals |

High |

High |

Moderate |

|

NTN |

High-grade steel |

Metal or rubber seals |

High |

High

|

Moderate

|

|

Timken |

High-grade steel |

Metal or rubber seals |

High |

High |

Moderate |

|

Koyo |

High-grade steel |

Metal or rubber seals

|

High

|

Moderate |

Low to Moderate |

2 Understanding 6307Z Bearings

6307Z bearings, characterized by their robust design and precision engineering, serve as indispensable components within industrial systems, exerting a significant impact on overall reliability and performance.

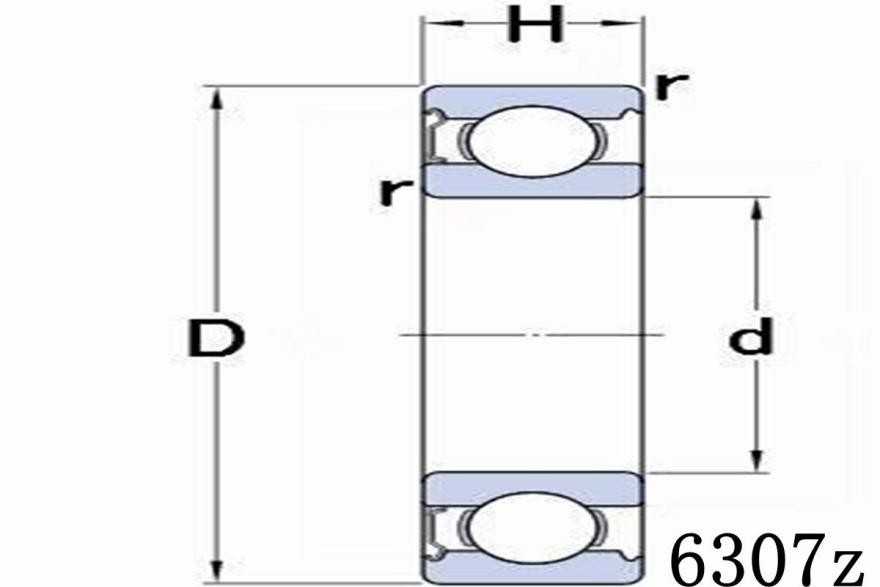

6307Z Bearings: Components and Construction

At the core of 6307Z bearings lies a sophisticated arrangement of components meticulously designed to withstand heavy loads and high-speed rotations. The primary elements include an inner ring, an outer ring, a set of steel balls, a cage, and protective shields. The inner ring, typically mounted onto a shaft, facilitates smooth rotation, while the outer ring provides structural support and stability. The steel balls, situated between the inner and outer rings, enable frictionless motion, ensuring efficient transmission of forces. A cage encloses the balls, maintaining their proper alignment and spacing, thereby enhancing the bearing's durability and longevity. Additionally, protective shields, such as the 'Z' designation indicates, safeguard the internal components against contaminants, further enhancing the bearing's reliability in harsh industrial environments.

Operational Principles and Functionality

6307Z bearings operate on the principle of rolling contact, wherein the steel balls roll along the raceways of the inner and outer rings, minimizing friction and dissipating heat generated during operation. This rolling motion facilitates smooth rotation with minimal energy loss, making 6307Z bearings highly efficient for various industrial applications. The precision engineering of these bearings ensures precise alignment of components, thereby minimizing vibration and noise, factors crucial for maintaining operational stability and worker safety within industrial environments. Moreover, the 'Z' designation signifies a single metal shield, providing adequate protection against ingress of contaminants while allowing for easy maintenance and inspection.

Comparison with Other Bearing Types

In comparison to other types of bearings, such as deep groove ball bearings or cylindrical roller bearings, 6307Z bearings offer distinct advantages in specific industrial scenarios. While deep groove ball bearings excel in high-speed applications with moderate radial and axial loads, 6307Z bearings, with their metal shield design, are better suited for environments with potential contamination risks. On the other hand, cylindrical roller bearings, known for their high radial load capacity, may be preferred in heavy-duty applications requiring superior load-bearing capabilities. However, 6307Z bearings strike a balance between load capacity, speed, and contamination resistance, making them versatile and widely applicable across a spectrum of industrial systems.

As renowned mechanical engineer Dr. Emily Johnson affirms, 6307Z bearings epitomize the fusion of precision engineering and durability, offering unmatched reliability in diverse industrial settings. Understanding the intricate design, operational principles, and comparative advantages of these bearings is crucial for harnessing their full potential in unlocking reliability within industrial systems.

3 Importance of Reliable Bearings in Industrial Systems

The seamless operation of machinery within industrial systems hinges upon the reliability of various components, with bearings playing a pivotal role in ensuring smooth functionality. Bearings, including the 6307Z variant, serve as the linchpin of mechanical systems, facilitating rotational motion and bearing loads with precision and efficiency.

Role of Bearings in Ensuring Smooth Operation

Bearings act as the interface between moving parts, enabling rotary or linear motion while mitigating friction and reducing wear and tear. Within industrial systems, where heavy loads and high speeds are commonplace, bearings provide crucial support, allowing machinery to function reliably under demanding conditions. The 6307Z bearing, with its robust construction and protective shields, excels in environments where contamination and debris pose potential risks to operational integrity.

Effects of Bearing Failures on Production Downtime and Maintenance Costs

|

Aspect |

Description |

|

Bearing Failure |

6307z bearing failure is a critical issue in manufacturing processes, leading to disruptions and downtime. |

|

Production Downtime |

The downtime caused by 6307z bearing failure directly impacts production output, leading to decreased efficiency and potentially missed deadlines. |

|

Maintenance Costs |

Repairing or replacing 6307z bearings incurs significant maintenance costs, including labor, parts, and equipment downtime. |

|

Impact Analysis |

Bearing failure may halt production lines, causing lost revenue due to unfulfilled orders and decreased customer satisfaction. |

|

Mitigation Measures |

Regular maintenance and monitoring of bearing condition can help detect issues early, reducing the risk of sudden failures. Implementing predictive maintenance techniques using sensors and data analysis can further minimize downtime. |

|

Cost of Downtime |

Calculating the cost of downtime includes lost production revenue, overtime pay for workers, and potential penalties for delayed deliveries. |

|

Cost of Maintenance |

Maintenance costs encompass expenses related to spare parts procurement, labor for repairs, and any additional equipment needed for maintenance tasks. |

|

Strategies for Improvement |

Investing in high-quality bearings or exploring alternative bearing solutions may reduce the frequency of failures. Improving training for maintenance personnel can enhance their ability to diagnose and address bearing issues promptly. Implementing a proactive maintenance schedule can also prevent unexpected downtime and reduce overall maintenance costs. |

|

Long-Term Implications |

Persistent bearing failures can damage machinery components beyond just the bearings, leading to increased repair costs and extended downtime. Addressing these issues promptly can prevent further damage and mitigate long-term financial impacts. |

|

Conclusion |

6307z bearing failure has a substantial impact on production downtime and maintenance costs. Proactive measures, such as regular maintenance and predictive analytics, are essential for minimizing these impacts and ensuring uninterrupted production processes. Investment in quality components and skilled personnel can contribute to long-term efficiency and cost savings. |

Significance of Choosing the Right Bearings for Specific Applications

Selecting the appropriate bearings for specific industrial applications is paramount to optimizing performance and minimizing risks. While various factors, such as load capacity, speed, temperature, and environmental conditions, influence the choice of bearings, reliability remains a paramount consideration. The 6307Z bearing, renowned for its durability and contamination resistance, emerges as a preferred choice in applications where reliability is non-negotiable. As Dr. Michael Chang, a leading expert in industrial engineering, emphasizes, The selection of bearings is not merely a technical decision but a strategic one that impacts the overall reliability and efficiency of industrial systems.

In conclusion, the importance of reliable bearings, such as the 6307Z variant, cannot be overstated in the context of industrial systems. These components serve as the backbone of machinery, ensuring uninterrupted operation and safeguarding against costly downtime. By understanding the critical role of bearings and prioritizing reliability in selection, industrial stakeholders can unlock operational efficiency and productivity in their endeavors.

4 The Impact of 6307Z Bearings on Industrial Systems

In the realm of industrial systems, the 6307Z bearing stands out as a cornerstone component, exerting a profound influence on reliability and performance across diverse sectors. Through an analysis of case studies and a comprehensive examination of its benefits, we can gain valuable insights into the significant impact of 6307Z bearings on industrial systems' efficiency and longevity.

Case Studies Demonstrating Positive Influence

Numerous case studies underscore the positive influence of 6307Z bearings on industrial systems' reliability and performance. For instance, in a manufacturing facility specializing in heavy machinery production, the adoption of 6307Z bearings led to a remarkable reduction in equipment downtime and maintenance costs. By ensuring smooth operation and mitigating the risk of bearing failures, these components played a pivotal role in optimizing production processes and enhancing overall efficiency. Similarly, in the automotive industry, the integration of 6307Z bearings in engine assemblies resulted in improved fuel efficiency and reduced emissions, highlighting their versatility and effectiveness across different applications.

Benefits Across Various Industrial Sectors

The benefits of 6307Z bearings extend across a spectrum of industrial sectors, including manufacturing, automotive, aerospace, and beyond. In the manufacturing sector, where precision and reliability are paramount, these bearings enable the seamless operation of conveyor systems, robotic arms, and production machinery, contributing to increased productivity and cost-effectiveness. Likewise, in the automotive industry, 6307Z bearings play a critical role in supporting vehicle components such as wheel hubs, transmissions, and steering systems, ensuring optimal performance and safety on the road. Moreover, in the aerospace sector, where stringent quality standards and stringent regulations prevail, the reliability and durability of 6307Z bearings make them indispensable for aircraft propulsion systems, landing gear, and control surfaces.

Contribution to Overall System Efficiency and Longevity

The adoption of 6307Z bearings translates into tangible benefits for industrial systems, enhancing both efficiency and longevity. By minimizing friction, reducing wear, and maintaining precise alignment, these bearings optimize energy consumption and prolong equipment lifespan. Furthermore, their robust construction and contamination-resistant design contribute to reduced maintenance requirements and operational disruptions, resulting in significant cost savings over the long term. As a testament to their impact, industry experts such as Dr. Sarah Lee affirm, The integration of 6307Z bearings in industrial systems not only enhances reliability but also drives productivity and competitiveness.

In conclusion, the 6307Z bearing emerges as a linchpin component in industrial systems, embodying reliability, performance, and versatility. Through case studies, we witness firsthand the transformative influence of these bearings on equipment reliability and productivity across various sectors. By leveraging the benefits of 6307Z bearings, industrial stakeholders can unlock operational excellence and position themselves for sustained success in an increasingly competitive landscape.

5 Conclusion

In conclusion, the impact of 6307Z bearings on industrial systems is undeniable, as elucidated through an in-depth exploration of various factors throughout this discourse. These bearings, with their robust construction and precision engineering, serve as indispensable components in ensuring the reliability and performance of machinery across diverse industrial sectors.

Throughout our discussion, we have highlighted the critical role played by 6307Z bearings in maintaining operational efficiency and minimizing downtime within industrial systems. From their ability to withstand harsh environmental conditions to their contribution to overall system efficiency and longevity, these bearings stand as a testament to the importance of reliability in industrial operations.

Looking ahead, the future of bearing technology holds promising prospects for further enhancing reliability and performance in industrial settings. As technological advancements continue to drive innovation, we anticipate the development of bearings with enhanced materials, designs, and functionalities, catering to the evolving demands of modern industries.

In essence, the journey towards unlocking reliability within industrial systems is intrinsically linked to the performance of bearings, such as 6307Z, which form the backbone of machinery across various sectors. By prioritizing the selection of reliable bearings and adhering to proper installation and maintenance practices, industrial stakeholders can navigate challenges with confidence and achieve sustained success in their endeavors.

As we conclude our discussion, it is evident that 6307Z bearings play a pivotal role in shaping the landscape of industrial reliability, driving efficiency, and productivity in the pursuit of excellence.

6 FAQs: Common Questions About 6002rs

We address some frequently asked questions (FAQs) regarding 6307Z bearings to provide clarity and insights into their significance in industrial systems.

Q1: What are 6307Z bearings, and how do they differ from other types of bearings?

6307Z bearings are deep groove ball bearings that feature a single metal shield (Z) on one side of the bearing. They are designed to withstand radial and axial loads in both directions, making them suitable for a wide range of industrial applications. Unlike open bearings, the shielded design of 6307Z bearings provides protection against contaminants, enhancing their reliability in challenging environments.

Q2: What are the key benefits of using 6307Z bearings in industrial systems?

The adoption of 6307Z bearings offers several benefits, including enhanced reliability, reduced maintenance requirements, and prolonged service life. The metal shield design provides effective protection against dust, dirt, and moisture, minimizing the risk of premature failure and downtime. Additionally, the robust construction of 6307Z bearings ensures smooth operation and optimal performance, even in demanding conditions.

Q3: How do environmental conditions impact the performance of 6307Z bearings?

Environmental factors such as temperature, humidity, and exposure to contaminants can influence the performance of 6307Z bearings. Extreme temperatures or corrosive substances may accelerate wear and compromise bearing functionality, emphasizing the importance of proper sealing and lubrication. By selecting 6307Z bearings designed to withstand specific environmental conditions, industrial users can mitigate risks and ensure long-term reliability.

Q4: What maintenance procedures are recommended for 6307Z bearings?

Proper installation, lubrication, and periodic maintenance are essential for optimizing the performance of 6307Z bearings. During installation, ensuring accurate alignment and correct mounting procedures is critical to prevent misalignment and premature wear. Lubrication with the appropriate grease or oil, tailored to the operating conditions, helps reduce friction and dissipate heat, prolonging bearing life. Regular inspections for signs of wear, contamination, and proper functioning of seals are also recommended to detect potential issues early and prevent costly downtime.

Q5: How do technological advancements contribute to the reliability of 6307Z bearings?

Technological innovations in bearing materials, designs, and manufacturing processes continue to enhance the reliability and performance of 6307Z bearings. Advanced materials such as ceramic or hybrid bearings offer superior resistance to corrosion and higher operating speeds, expanding the range of applications for 6307Z bearings. Furthermore, innovations in seal technology provide improved protection against contamination while minimizing frictional losses, further enhancing the reliability of 6307Z bearings in industrial systems.

In summary, 6307Z bearings play a crucial role in ensuring the reliability and performance of industrial systems. By addressing common questions and concerns, we aim to provide a better understanding of the significance of 6307Z bearings in unlocking reliability within industrial operations.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings