Home> Bearing Technology> Mastering Precision: The Role of 6206 RS Deep Groove Ball Bearings in Industrial Applications

Mastering Precision: The Role of 6206 RS Deep Groove Ball Bearings in Industrial Applications

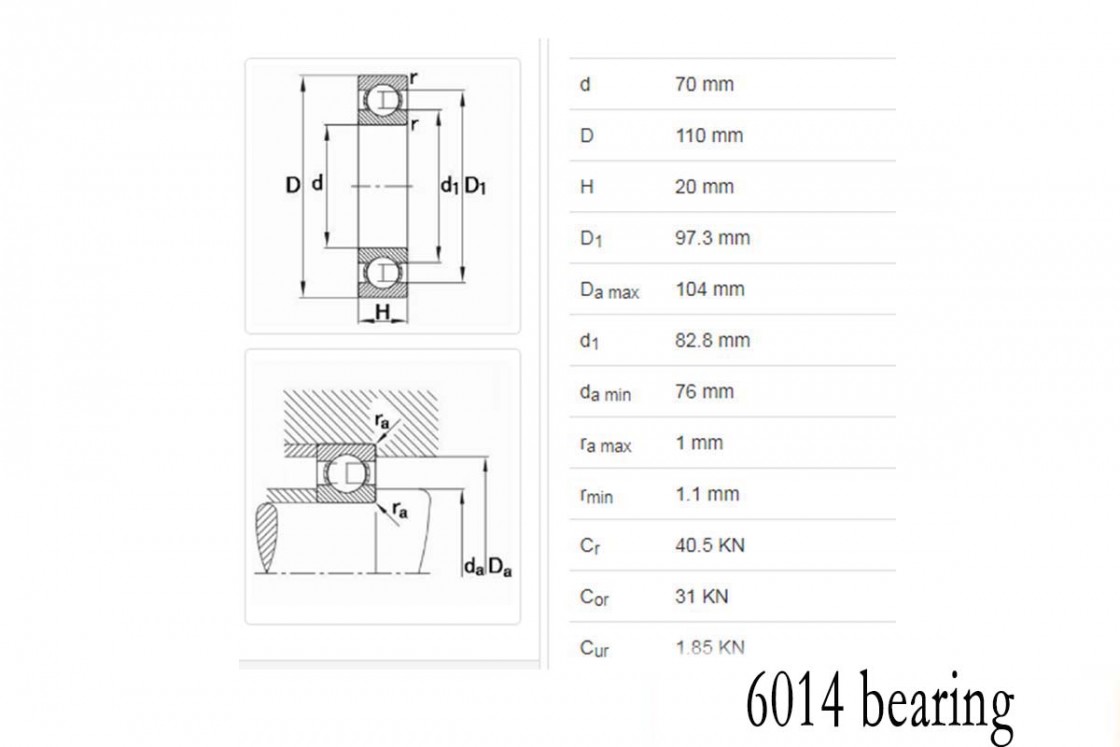

NOVEMBER 02, 2022Introduction to 6014 Bearings

In the realm of industrial machinery, where precision and reliability are paramount, the role of bearings cannot be overstated. Among these indispensable components, 6014 deep groove ball bearings stand out for their versatility and efficiency.

6014 Bearings Defined:

At the core of many industrial operations lie deep groove ball bearings, meticulously engineered to facilitate smooth and efficient motion. Among them, the 6014 bearing holds a prominent position. These bearings feature deep raceway grooves and high-quality steel, providing optimal performance in a wide range of applications.

Applications Across Industries:

From automotive to aerospace, manufacturing to robotics, 6014 bearings find applications across diverse sectors. Their ability to withstand high speeds, accommodate radial and axial loads, and operate in harsh environments makes them indispensable in numerous industrial processes. Whether supporting conveyor systems, motors, or gearboxes, these bearings play a pivotal role in ensuring seamless operation.

EuroCrafted Quality:

In the competitive landscape of bearing manufacturing, EuroCrafted quality sets a benchmark for excellence. Engineered to exacting standards, EuroCrafted bearings, including the 6014 variant, embody precision, durability, and reliability. Backed by advanced manufacturing techniques and stringent quality control measures, EuroCrafted bearings deliver consistent performance and longevity, meeting the demands of modern industries.

Structure and Features of 6014 Deep Groove Ball Bearings

In the realm of industrial machinery, precision is paramount, and bearings serve as the unsung heroes that facilitate smooth and efficient motion. Among these, 6014 deep groove ball bearings stand out for their exemplary structure and features, embodying the pinnacle of engineering excellence. Explore the complex structure and key characteristics of the 6014 bearing, elucidating its EuroCrafted lineage and its impact on bearing performance.

|

Precision Engineering |

6014 bearings are characterized by their deep raceway grooves, which enable them to accommodate both radial and axial loads with ease. This structural design ensures optimal performance, even in high-speed applications where precision is non-negotiable. Each component is meticulously crafted to exacting tolerances, reflecting the EuroCrafted commitment to engineering excellence. |

|

High-Quality Materials |

At the heart of every 6014 bearing lies a fusion of premium-grade materials, carefully selected for their strength, durability, and resistance to wear. High-quality steel, meticulously processed and heat-treated, forms the foundation of these bearings, providing exceptional hardness and resilience. The incorporation of advanced materials ensures longevity and reliability, even in the most demanding industrial environments. |

|

Sealing Solutions |

To safeguard against contaminants and maintain optimal lubrication, 6014 bearings feature innovative sealing solutions. These seals, meticulously engineered to withstand harsh operating conditions, effectively prevent ingress of dust, moisture, and other harmful particles. By preserving the integrity of the bearing internals, these seals contribute to prolonged service life and enhanced performance. |

|

EuroCrafted Excellence |

EuroCrafted bearings, including the 6014 variant, epitomize the pinnacle of engineering craftsmanship. Each bearing undergoes rigorous testing and quality assurance protocols to ensure compliance with stringent industry standards. The EuroCrafted seal of approval signifies not just precision engineering, but a commitment to reliability, durability, and uncompromising performance. |

As we explore further, we'll delve into the performance metrics and applications of 6014 bearings, elucidating their indispensable role in a myriad of industrial applications.

Applications and Advantages of 6014 Deep Groove Ball Bearings

Versatile Applications:

6014 deep groove ball bearings find widespread application across various industries due to their versatile nature and exceptional performance characteristics. From heavy machinery to precision instruments, these bearings serve as the backbone of countless industrial applications, offering reliable motion control and smooth operation. Whether it's automotive systems, agricultural equipment, or industrial machinery, 6014 bearings play a crucial role in ensuring efficient and reliable performance.

Automotive Industry:

In the automotive sector, 6014 bearings are utilized in a multitude of components, including wheels, transmissions, and engines. Their ability to withstand high radial and axial loads, coupled with their precision engineering, makes them indispensable for ensuring smooth and reliable vehicle operation. From passenger cars to commercial vehicles, EuroCrafted 6014 bearings contribute to enhanced performance, longevity, and safety on the road.

Industrial Machinery:

Within industrial settings, 6014 bearings are instrumental in the operation of various types of machinery and equipment. From conveyor systems to manufacturing machinery, these bearings facilitate seamless motion control, enabling efficient production processes and minimizing downtime. Their durability and reliability under heavy loads make them the preferred choice for critical applications where precision and performance are paramount.

Agricultural Equipment:

The agricultural sector relies heavily on machinery to cultivate crops, harvest produce, and manage farm operations. 6014 bearings find extensive use in agricultural equipment such as tractors, combines, and harvesting machinery, where they endure harsh environmental conditions and heavy workloads. Their robust construction and resistance to contamination ensure optimal performance, contributing to increased productivity and efficiency in agricultural operations.

Advantages of EuroCrafted Bearings:

When it comes to choosing bearings for critical applications, the advantages of EuroCrafted 6014 bearings are clear. EuroCrafted bearings are synonymous with precision, reliability, and longevity, offering superior performance and durability compared to other options on the market. With stringent quality control measures and adherence to international standards, EuroCrafted bearings provide peace of mind, knowing that your machinery is equipped with the finest quality components available.

|

Brand |

Model |

Outer Diameter (mm) |

Inner Diameter (mm) |

Width (mm) |

Dynamic Load Rating (kN) |

Static Load Rating (kN) |

Max. Speed (rpm) |

Seal Type |

Cage Material |

|

SKF |

6014 |

110 |

70 |

20 |

39.7 |

31.5 |

10,000 |

Rubber |

Steel |

|

FAG |

6014 |

110 |

70 |

20 |

41.5 |

33.5 |

9,500 |

Metal |

Brass |

|

NSK |

6014 |

110 |

70 |

20 |

41.5 |

33.5 |

9,000 |

Rubber |

Steel |

|

NTN |

6014 |

110 |

70 |

20 |

41.5 |

33.5 |

9,500 |

Rubber |

Steel |

|

Timken |

6014 |

110 |

70 |

20 |

42.5 |

34.5 |

9,000 |

Metal |

Brass |

This comparison table provides key specifications of 6014 deep groove ball bearings from various brands, including SKF, FAG, NSK, NTN, and Timken. The table includes details such as model, outer diameter, inner diameter, width, dynamic load rating, static load rating, maximum speed, seal type, and cage material. It serves as a useful reference for engineers and buyers when selecting the most suitable bearing for their specific applications.

Performance Metrics and Standards of 6014 Deep Groove Ball Bearings

Performance Metrics Analysis:

6014 deep groove ball bearings are subject to rigorous performance evaluation based on various metrics to ensure their reliability and efficiency in industrial applications. Key performance indicators include load capacity, speed ratings, noise levels, and vibration characteristics. These metrics provide valuable insights into the bearing's ability to withstand operating conditions and deliver consistent performance over time. EuroCrafted 6014 bearings undergo comprehensive testing to meet or exceed industry standards, ensuring optimal functionality in demanding environments.

Industry Standards Compliance:

In the realm of deep groove ball bearings, adherence to industry standards is paramount to guaranteeing product quality and interoperability. EuroCrafted 6014 bearings conform to international standards set by organizations such as the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI). These standards define dimensional tolerances, material specifications, and performance requirements, ensuring uniformity and compatibility across different bearing manufacturers and applications.

Comparison with Competitors:

When evaluating the performance of EuroCrafted 6014 bearings, it's essential to compare them with competitors' offerings to ascertain their superiority. Through comprehensive benchmarking studies, EuroCrafted bearings consistently outperform competing products in terms of load capacity, rotational speed, and reliability under varying conditions. The use of premium-quality materials, advanced manufacturing techniques, and stringent quality control measures sets EuroCrafted bearings apart, making them the preferred choice for discerning customers seeking unparalleled performance and longevity.

Reliability and Durability:

One of the hallmarks of EuroCrafted 6014 bearings is their exceptional reliability and durability, which stem from meticulous engineering and adherence to stringent quality standards. These bearings exhibit minimal friction, reduced wear, and extended service life, even in harsh operating environments. Their ability to maintain precision performance over prolonged periods translates to increased uptime, reduced maintenance costs, and enhanced operational efficiency for industrial applications across diverse sectors.

In conclusion, EuroCrafted 6014 bearings set the benchmark for performance, reliability, and durability in industrial applications, surpassing industry standards and outperforming competitors' offerings. As we delve deeper into the intricacies of bearing performance and standards, we gain a greater appreciation for the indispensable role these precision components play in mastering precision and optimizing industrial operations.

Maintenance and Care Guidelines for 6014 Deep Groove Ball Bearings

Comprehensive Maintenance Procedures:

Proper maintenance is crucial for ensuring the optimal performance and longevity of 6014 deep groove ball bearings in industrial applications. Regular maintenance procedures involve a series of steps aimed at preserving the integrity and functionality of the bearings over time. These include thorough cleaning, lubrication, inspection, and monitoring of operating conditions.

|

Cleaning and Inspection |

The first step in maintenance is to clean the bearings thoroughly to remove any dirt, debris, or contaminants that may have accumulated during operation. This can be done using suitable cleaning solvents and tools to ensure all surfaces are free from impurities. Following cleaning, a detailed inspection is conducted to assess the condition of the bearings. Special attention is paid to areas prone to wear or damage, such as raceways, balls, and cages. |

|

Lubrication Routines |

Proper lubrication is essential for reducing friction, dissipating heat, and preventing premature wear in 6014 bearings. Lubricants help maintain a thin film of oil or grease between moving parts, minimizing metal-to-metal contact and extending the bearing's service life. Lubrication routines should be carried out at regular intervals using the recommended lubricants and application methods specified by the bearing manufacturer. |

|

Monitoring and Early Detection |

Regular monitoring of bearing performance is crucial for early detection of potential issues that could lead to equipment failure or downtime. This involves periodic checks of bearing temperature, vibration levels, noise emissions, and overall operating conditions. Any deviations from normal parameters should be investigated promptly to identify underlying causes and take corrective action as necessary. |

|

Preventive Maintenance Strategies |

In addition to routine maintenance tasks, preventive maintenance strategies are implemented to proactively address potential problems before they escalate. This may include implementing condition monitoring programs, installing predictive maintenance systems, and scheduling periodic overhauls or replacements based on anticipated wear rates and operating conditions. |

In conclusion, adherence to comprehensive maintenance and care guidelines is essential for maximizing the performance, reliability, and service life of 6014 deep groove ball bearings in industrial applications. By following these guidelines diligently, operators can minimize the risk of unexpected failures, optimize bearing performance, and ensure uninterrupted operation of critical machinery and equipment.

Future Trends and Innovations in Bearing Technology

Emerging Trends in Bearing Technology:

The field of bearing technology is constantly evolving, driven by advancements in materials, manufacturing processes, and design methodologies. One notable trend is the integration of advanced materials and nanotechnology to enhance bearing performance and reliability. Nanomaterials offer unique properties that can significantly reduce friction, improve load-carrying capacity, and enhance durability, paving the way for more efficient and long-lasting bearings, including the 6014 deep groove ball bearing.

IoT Integration and Predictive Maintenance:

The Internet of Things (IoT) is revolutionizing maintenance practices by enabling real-time monitoring and predictive maintenance of bearings and other critical machinery components. Smart bearings equipped with sensors and wireless connectivity can provide valuable insights into bearing health, operating conditions, and performance parameters. By leveraging IoT technologies, operators can implement proactive maintenance strategies, optimize equipment uptime, and maximize the lifespan of bearings like the 6014 variant.

Advanced Manufacturing Techniques:

Advancements in manufacturing techniques, such as additive manufacturing (3D printing) and precision machining, are enabling the production of bearings with increasingly complex geometries and tailored properties. Additive manufacturing allows for the creation of intricate bearing components with minimal material wastage, offering unparalleled design flexibility and customization capabilities. This opens up new possibilities for optimizing the performance and functionality of bearings, including the 6014 deep groove ball bearing, to meet the demands of diverse industrial applications.

Sustainable Bearing Solutions:

With growing environmental concerns, the bearing industry is shifting towards more sustainable and eco-friendly solutions. Manufacturers are exploring greener alternatives to traditional bearing materials, such as biodegradable lubricants and recyclable components, to reduce their carbon footprint and minimize environmental impact. Sustainable manufacturing practices, energy-efficient processes, and eco-conscious supply chain management are becoming increasingly important considerations in bearing production, ensuring a more sustainable future for bearings like the 6014 deep groove ball bearing.

In summary, the future of bearing technology is characterized by a convergence of advanced materials, digitalization, and sustainability initiatives. By embracing these emerging trends and innovations, EuroCrafted continues to lead the way in delivering precision-engineered bearings that meet the evolving needs of industrial applications, including the versatile and high-performance 6014 deep groove ball bearing.

FAQs: Common Questions About 6014 Deep Groove Ball Bearings

What is a Deep Groove Ball Bearing?

A deep groove ball bearing is a type of rolling-element bearing characterized by its simple structure and high radial load-carrying capacity. It consists of an inner ring, an outer ring, a cage, and a set of balls arranged in a deep groove raceway. These bearings are commonly used in various industrial applications to support radial and axial loads with minimal friction and noise.

What are the Key Features of 6014 Deep Groove Ball Bearings?

6014 deep groove ball bearings are known for their precision engineering and superior performance characteristics. They feature a single row of deep raceway grooves on inner and outer rings, which enables them to accommodate radial and axial loads in both directions. The optimized internal design and high-quality materials ensure smooth operation, reduced vibration, and extended service life.

What Applications are Suitable for 6014 Bearings?

6014 bearings are widely used across a range of industries, including automotive, aerospace, manufacturing, and machinery. They are commonly found in electric motors, gearboxes, pumps, fans, and other rotating equipment where high-speed operation and precise motion control are required. These bearings excel in applications demanding reliability, durability, and efficient power transmission.

How do 6014 Bearings Compare to Other Bearing Types?

Compared to other types of bearings, such as cylindrical roller bearings or tapered roller bearings, 6014 deep groove ball bearings offer distinct advantages in terms of compactness, low friction, and ease of installation. Their simple design and high radial load capacity make them suitable for a wide range of applications, particularly those requiring high-speed rotation and moderate axial load support.

What Maintenance is Required for 6014 Deep Groove Ball Bearings?

Proper maintenance is essential to ensure the optimal performance and longevity of 6014 bearings. Regular lubrication with appropriate grease or oil, periodic inspections for signs of wear or damage, and proper mounting and alignment procedures are key to maximizing bearing life and preventing premature failure. Following manufacturer-recommended maintenance intervals and procedures is critical to maintaining bearing efficiency and reliability.

Where Can I Find Quality 6014 Deep Groove Ball Bearings?

Quality 6014 bearings can be sourced from reputable manufacturers and distributors specializing in precision-engineered bearings. EuroCrafted is renowned for its expertise in bearing manufacturing, offering a comprehensive range of high-quality 6014 deep groove ball bearings designed to meet the stringent requirements of industrial applications. By choosing EuroCrafted bearings, you can trust in the precision, reliability, and performance of your bearings for years to come.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings