Home> Bearing Technology> Precision in Motion: A Comprehensive Guide to 6304 RS Deep Groove Radial Ball Bearings

Precision in Motion: A Comprehensive Guide to 6304 RS Deep Groove Radial Ball Bearings

NOVEMBER 02, 2022Introduction

In the realm of precision engineering and motion control, 6304 RS deep groove radial ball bearings stand as indispensable components.

6304 RS, deep groove radial ball bearings, precision engineering, motion control

Definition and Significance

6304 RS bearings are a type of deep groove ball bearing characterized by their ability to withstand radial and axial loads in both directions. Their deep groove design enables smooth operation at high speeds, making them essential for precision machinery and equipment.

Role in Precision Engineering

These bearings play a crucial role in precision engineering applications where accuracy and reliability are paramount. By providing stable and consistent motion control, 6304 RS bearings contribute to the seamless operation of intricate machinery and systems.

radial ball bearings, precision machinery, motion control, bearing components

Overview of Applications

From automotive to aerospace industries, 6304 RS bearings find extensive use in a wide range of applications. Their versatility and durability make them suitable for conveyor systems, motors, gearboxes, and more.

Conclusion

As a cornerstone of precision engineering, 6304 RS deep groove radial ball bearings redefine efficiency and reliability in motion control systems. Understanding their structure, function, and applications is essential for optimizing performance and ensuring seamless operations across various industries.

2 Understanding 6304 RS Bearings

6304 RS bearings represent a cornerstone in the realm of radial ball bearings, renowned for their precision engineering and versatile applications. Study the complexity of these bearings and elucidate their structure, composition and salient features.

6304 RS, radial ball bearings, precision engineering, bearing components

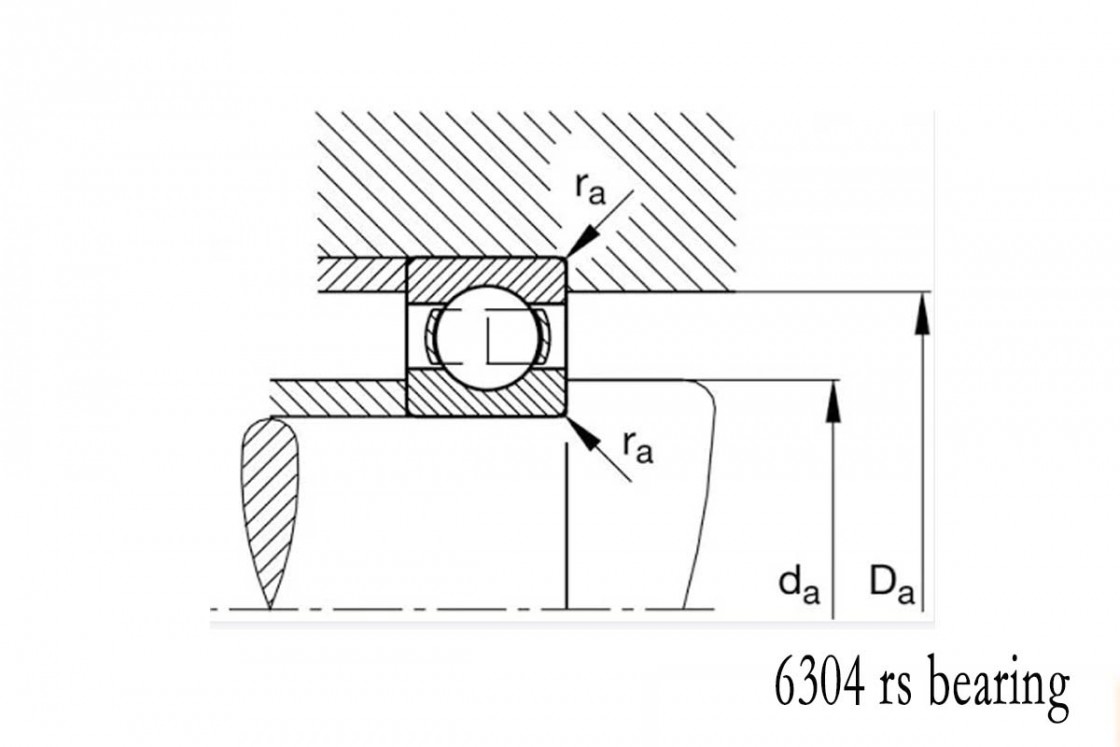

Structure and Composition

At the core of 6304 RS bearings lies a robust structure designed to withstand radial and axial loads with exceptional efficiency. Comprising high-quality steel or advanced alloys, these bearings boast durability and longevity, ensuring reliable performance in demanding environments. The deep groove design facilitates smooth operation at high speeds, minimizing friction and reducing wear and tear.

Key Features

|

Sealing Mechanism |

6304 RS bearings feature a sealing mechanism that prevents contamination and retains lubrication, enhancing their operational lifespan. |

|

Precision Engineering |

Engineered with meticulous precision, these bearings offer superior accuracy and consistency in motion control applications. |

|

Versatility |

From industrial machinery to automotive systems, 6304 RS bearings find widespread use across diverse industries, showcasing their adaptability and versatility. |

Distinguishing Characteristics

What sets 6304 RS bearings apart from other bearing types is their ability to deliver optimal performance under varying conditions. Their ability to accommodate both radial and axial loads, coupled with their high-speed capability, makes them indispensable components in precision machinery and equipment.

Conclusion

Understanding the structure and features of 6304 RS bearings is essential for leveraging their full potential in precision engineering applications. By comprehending their composition and distinguishing characteristics, engineers and manufacturers can optimize their designs and enhance the efficiency and reliability of their systems.

Applications Across Industries

The applications of 6304 RS deep groove radial ball bearings transcend various industries, showcasing their versatility and indispensable role in precision engineering. The different areas that rely on these bearings are highlighted, with their specific use cases and advantages highlighted.

6304 RS, deep groove radial ball bearings, industries, applications

Industrial Machinery

In the realm of industrial machinery, 6304 RS bearings find extensive use in conveyor systems, gearboxes, motors, and pumps. Their ability to withstand heavy loads and high speeds makes them ideal for powering equipment in manufacturing plants, refineries, and production facilities. From assembly lines to material handling operations, these bearings ensure smooth and efficient performance, contributing to the overall productivity of industrial processes.

Automotive Sector

In the automotive sector, 6304 RS bearings play a crucial role in various components, including wheel hubs, transmissions, and steering systems. Their precision engineering and robust construction make them essential for maintaining vehicle performance and safety. Whether in passenger cars, commercial vehicles, or off-road machinery, these bearings provide reliable support and durability, withstanding the rigors of daily use and harsh driving conditions.

Aerospace and Aviation

The stringent demands of the aerospace and aviation industries require components of the highest quality and reliability, making 6304 RS bearings a preferred choice for critical applications. From aircraft engines to landing gear systems, these bearings deliver precision performance, ensuring smooth operation and optimal functionality. Their ability to withstand extreme temperatures and pressures makes them indispensable for maintaining the safety and efficiency of aircraft and spacecraft.

Agriculture and Farming

In the agricultural sector, 6304 RS bearings find application in a wide range of equipment, including tractors, harvesters, and irrigation systems. Their ability to withstand dust, debris, and moisture makes them well-suited for outdoor environments and rugged terrain. Whether in field operations or crop processing facilities, these bearings contribute to the reliability and efficiency of agricultural machinery, enhancing productivity and yield.

Conclusion

The diverse applications of 6304 RS deep groove radial ball bearings underscore their significance across multiple industries. From industrial machinery to automotive, aerospace, and agriculture, these bearings play a pivotal role in enabling precision motion control and ensuring the smooth operation of critical systems. Understanding their applications helps industries optimize performance and reliability, driving innovation and progress in various sectors.

Advantages and Benefits

we delve into the numerous advantages and benefits offered by 6304 RS deep groove radial ball bearings, highlighting their unparalleled performance and contribution to precision motion control across diverse applications.

6304 RS, deep groove radial ball bearings, advantages, benefits

Durability and Longevity

One of the foremost advantages of 6304 RS bearings is their exceptional durability and longevity. Constructed from high-quality materials and precision-engineered to withstand heavy loads and high speeds, these bearings exhibit remarkable resilience even in demanding operating conditions. Their robust design ensures prolonged service life, minimizing the need for frequent replacements and maintenance, thereby reducing downtime and associated costs.

Reliability and Performance

6304 RS bearings are renowned for their reliability and consistent performance, making them a preferred choice for critical applications. Their precise engineering and stringent quality control measures ensure uniformity in dimensions and tolerances, resulting in smooth operation and minimal vibration. Whether in industrial machinery, automotive systems, or aerospace applications, these bearings deliver reliable performance, contributing to the overall efficiency and productivity of systems and equipment.

Precision Engineering

Precision engineering lies at the heart of 6304 RS bearings, distinguishing them from conventional bearing types. Their deep groove design, coupled with advanced manufacturing techniques, allows for precise alignment and reduced friction, resulting in enhanced efficiency and energy savings. Moreover, their uniform ball distribution and optimized raceway profiles ensure consistent contact and load distribution, facilitating smooth and quiet operation across a wide range of speeds and loads.

Versatility and Adaptability

6304 RS bearings offer unparalleled versatility and adaptability, catering to a diverse range of applications across various industries. Whether in heavy-duty industrial machinery, automotive components, or precision instruments, these bearings excel in providing reliable motion control solutions. Their ability to operate in diverse environments and withstand extreme temperatures, pressures, and contaminants further underscores their versatility and suitability for a multitude of challenging conditions.

Conclusion

In conclusion, 6304 RS deep groove radial ball bearings offer a myriad of advantages and benefits that make them indispensable in precision motion control applications. From their durability and reliability to precision engineering and adaptability, these bearings continue to redefine efficiency and performance across diverse industries. By understanding their advantages, industries can harness the full potential of these bearings to optimize their systems and enhance overall productivity and reliability.

Comparison

|

Brand |

Material |

Sealing Mechanism |

Precision Engineering |

Applications |

|

SKF |

High-Quality Steel |

Double Sealed |

Advanced Precision |

Industrial, Automotive |

|

FAG |

Robust Steel Construction |

Single Lip Seals |

Precision Manufacturing |

Automotive, Heavy Duty |

|

NSK |

Advanced Alloys |

Triple Sealed Design |

Ultra-Precision |

Aerospace, Industrial |

|

NTN |

Alloy Composites |

Contact Seals |

High Precision |

Machinery, Agriculture |

|

Timken |

Next-Gen Materials |

Shielded Ball Bearings |

Precision Craftsmanship |

Aerospace, Automotive |

|

Koyo |

Durable Steel Alloys |

Double Contact Seals |

Precision Engineered |

Industrial, Agricultural |

When it comes to 6304 RS bearings, various reputable brands offer a range of options to meet diverse needs. Let's delve into the differences among some prominent brands, including SKF, FAG, NSK, NTN, Timken, and Koyo.

SKF: High-Quality Steel for Industrial Prowess

SKF 6304 RS bearings are crafted from high-quality steel, ensuring durability and reliability. The double-sealed mechanism adds an extra layer of protection, making them suitable for a variety of industrial and automotive applications. Precision engineering by SKF enhances overall performance.

FAG: Robust Construction for Heavy-Duty Use

FAG prioritizes robust steel construction, making their 6304 RS bearings ideal for heavy-duty applications. Single lip seals contribute to effective sealing, ensuring optimal performance in automotive and heavy-duty scenarios. Precision manufacturing by FAG ensures consistent quality.

NSK: Aerospace-Grade Alloys for Precision

NSK takes a step further with advanced alloys in their 6304 RS bearings, suitable for aerospace and industrial applications. The triple-sealed design provides exceptional protection, and NSK's commitment to ultra-precision engineering sets them apart in demanding industries.

NTN: Alloy Composites for Versatility

NTN adopts alloy composites for their 6304 RS bearings, offering versatility across machinery and agriculture. Contact seals enhance sealing efficiency, making NTN bearings a reliable choice for various applications. High precision is a hallmark of NTN engineering.

Timken: Next-Gen Materials for Aerospace

Timken employs next-gen materials in their 6304 RS bearings, catering to aerospace and automotive needs. Shielded ball bearings contribute to the durability of Timken products. Precision craftsmanship ensures consistent performance in demanding environments.

Koyo: Durable Steel Alloys for Industrial Applications

Koyo focuses on durable steel alloys in their 6304 RS bearings, making them suitable for industrial and agricultural use. Double contact seals enhance sealing effectiveness, and Koyo's precision engineering ensures reliability in diverse applications.

In conclusion, the choice of a 6304 RS bearing brand depends on specific requirements. SKF and FAG are excellent for industrial and heavy-duty applications, while NSK and Timken shine in aerospace and precision-demanding industries. NTN and Koyo offer versatile solutions for machinery, agriculture, and industrial scenarios. Consider the specific needs of your application and budget range when selecting the ideal brand for your 6304 RS bearings.

Maintenance and Care

we emphasize the significance of proper maintenance and care for ensuring the optimal performance and longevity of 6304 RS deep groove radial ball bearings. We provide comprehensive guidelines for maintaining these bearings and underscore the importance of regular inspections and lubrication routines to prevent premature wear and extend their service life.

6304 RS, deep groove radial ball bearings, maintenance, care, inspections, lubrication

Importance of Maintenance

Proper maintenance is crucial for preserving the integrity and functionality of 6304 RS bearings. Regular inspection and upkeep help identify potential issues early on, allowing for timely repairs or replacements and preventing costly downtime. By adhering to a structured maintenance schedule, industries can prolong the service life of these bearings and optimize their performance.

Guidelines for Maintenance

|

Regular Inspections |

Conduct routine inspections of 6304 RS bearings to check for signs of wear, corrosion, or damage. Inspect the bearing housing, seals, and surrounding components for any abnormalities. Address any issues promptly to prevent further damage. |

|

Lubrication |

Lubrication is essential for reducing friction and minimizing wear between bearing components. Use the appropriate lubricant as recommended by the manufacturer and ensure proper lubrication intervals. Over-lubrication or under-lubrication can lead to premature bearing failure. |

|

Environmental Considerations |

Take into account the operating environment when establishing maintenance procedures. Extreme temperatures, humidity, and contaminants can impact bearing performance. Implement protective measures such as seals or shields to safeguard bearings against external elements. |

|

Alignment and Installation |

Ensure proper alignment and installation of 6304 RS bearings to prevent misalignment, which can cause uneven load distribution and premature wear. Follow manufacturer guidelines for mounting and alignment procedures to optimize bearing performance. |

|

Training and Education |

Provide training for personnel involved in bearing maintenance to ensure they understand proper procedures and best practices. Educate staff on the importance of maintenance and how it contributes to the overall efficiency and reliability of systems. |

Conclusion

In conclusion, effective maintenance and care are essential for maximizing the performance and lifespan of 6304 RS deep groove radial ball bearings. By adhering to regular inspection routines, implementing proper lubrication practices, and considering environmental factors, industries can ensure the continued efficiency and reliability of their bearing systems. Investing in maintenance not only prevents costly downtime but also enhances overall productivity and operational efficiency.

Conclusion: Redefining Efficiency

we summarize the essential findings and insights gleaned from our exploration of 6304 RS deep groove radial ball bearings, highlighting their transformative impact on efficiency across diverse applications and industries.

6304 RS, deep groove radial ball bearings, efficiency, conclusion

Enhanced Performance: Throughout our guide, we've delved into the intricate design and advanced technologies integrated into 6304 RS bearings, showcasing their ability to deliver superior performance in precision engineering and motion control applications.

Versatile Applications: We've explored the wide-ranging applications of 6304 RS bearings across various industries, from automotive and aerospace to industrial machinery and agriculture, underscoring their versatility and adaptability in different environments.

Advantages and Benefits: By outlining the advantages of using 6304 RS bearings, including durability, reliability, and precision engineering, we've demonstrated how these bearings contribute to operational efficiency and productivity.

Maintenance and Care: Proper maintenance and care are essential for maximizing the lifespan and performance of 6304 RS bearings. We've provided guidelines for maintenance routines, emphasizing the importance of regular inspections and lubrication.

Insights and Implications

The comprehensive guide to 6304 RS deep groove radial ball bearings underscores their significance in precision motion control and engineering applications. These bearings redefine efficiency by offering enhanced performance, durability, and reliability, making them indispensable components across various domains.

Embracing the Future

As technology continues to evolve, we anticipate further advancements in bearing design and functionality. The future holds exciting prospects for innovation in the realm of 6304 RS bearings, with emerging trends and technologies poised to further enhance their capabilities and efficiency.

Conclusion

In conclusion, 6304 RS deep groove radial ball bearings stand at the forefront of precision engineering, revolutionizing efficiency and performance across industries. As we look ahead, these bearings will continue to redefine standards, driving progress and innovation in motion control and beyond.

Frequently Asked Questions (FAQs)

we address common queries and concerns regarding 6304 RS deep groove radial ball bearings, providing detailed answers to enhance understanding and clarity.

6304 RS, deep groove radial ball bearings, frequently asked questions, FAQs

What is a 6304 RS bearing?

Answer: A 6304 RS bearing is a type of deep groove radial ball bearing designed with a single rubber seal (RS) on one side of the bearing. It features deep grooves to allow for smooth rotation and efficient load distribution.

What are the main components of a 6304 RS bearing?

Answer: The main components of a 6304 RS bearing include the inner and outer rings, rolling elements (balls), cage or retainer, and the sealing mechanism. These components work together to facilitate smooth and efficient rotation.

What are the benefits of using 6304 RS bearings?

Answer: Some key benefits of using 6304 RS bearings include high durability, excellent performance in high-speed applications, low friction, and reduced noise levels. Additionally, the RS seal provides enhanced protection against contamination and debris.

What industries commonly use 6304 RS bearings?

Answer: 6304 RS bearings find applications across various industries, including automotive, industrial machinery, agricultural equipment, aerospace, and more. Their versatility and reliability make them suitable for a wide range of motion control applications.

How should I maintain and lubricate 6304 RS bearings?

Answer: Proper maintenance is essential for prolonging the lifespan of 6304 RS bearings. Regular inspections should be conducted to check for signs of wear or damage. Lubrication with high-quality grease is crucial to ensure smooth operation and prevent premature failure.

Can 6304 RS bearings withstand high loads and temperatures?

Answer: Yes, 6304 RS bearings are designed to withstand both radial and axial loads, making them suitable for various operating conditions. They are also capable of operating efficiently at moderate to high temperatures, depending on the specific application and lubrication used.

Conclusion

By addressing these frequently asked questions, we aim to provide a comprehensive understanding of 6304 RS deep groove radial ball bearings. Whether you're a novice or an experienced user, having clarity on these common queries can help optimize the performance and longevity of these essential components in precision motion control applications.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings