Home> Bearing Technology> Singapore's Role in Sealed Bearings: Origins, Utilizations, and Innovations Explored

Singapore's Role in Sealed Bearings: Origins, Utilizations, and Innovations Explored

NOVEMBER 02, 2022Introduction to Sealed Bearings

Bearings are essential components in various industries, facilitating smooth and efficient mechanical motion. They play a crucial role in machinery ranging from industrial equipment to automotive applications, supporting rotational or linear movement with reduced friction.

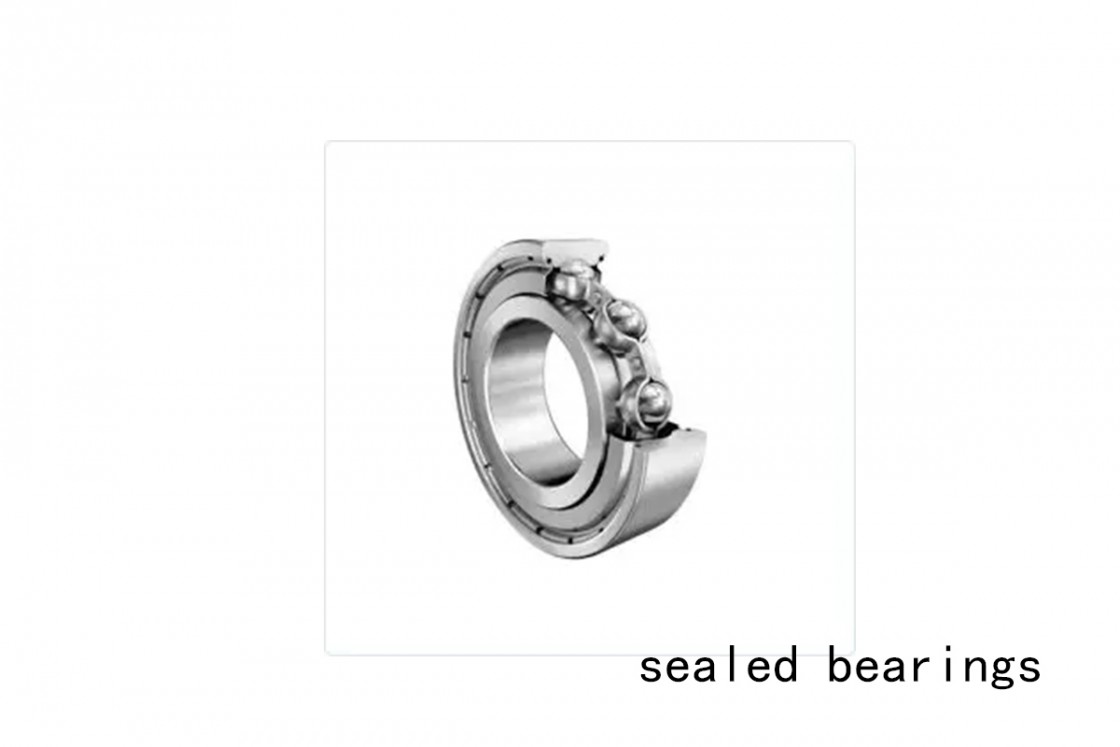

Sealed bearings represent a specialized type of bearing designed to enhance performance and longevity in challenging environments. Unlike traditional bearings, which require external lubrication and are susceptible to contamination, sealed bearings incorporate integrated seals that protect against dust, moisture, and other contaminants. This feature extends their service life and reduces maintenance requirements, making them ideal for applications where reliability and durability are paramount.

Singapore has emerged as a pivotal hub for technological advancements in various engineering fields, including bearing technologies. The nation's strategic location, coupled with a robust infrastructure and a conducive business environment, has attracted leading manufacturers and innovators in the bearing industry. This positioning has enabled Singapore to contribute significantly to the evolution and adoption of sealed bearings worldwide.

we will delve deeper into the origins of sealed bearings, explore their diverse applications across industries, and examine the latest innovations that are shaping the future of this critical technology.

Origins of Sealed Bearings in Singapore

The evolution of sealed bearings can be traced back to the mid-20th century, coinciding with rapid advancements in industrial manufacturing and engineering. Bearings, initially developed to support rotating machinery, soon became indispensable across a wide array of industries, from automotive to aerospace, due to their role in reducing friction and enabling precise motion.

Historical Background on the Development of Sealed Bearings Globally

Sealed bearings represented a significant leap forward in bearing technology. Traditional bearings required external lubrication, which necessitated frequent maintenance and exposed them to contamination risks. Sealed bearings addressed these challenges by integrating specially designed seals that protected internal components from environmental pollutants while retaining lubricants within the bearing housing. This innovation not only enhanced reliability but also prolonged operational life spans, making sealed bearings ideal for applications where reliability and minimal maintenance were critical.

Focus on Singapore's Entry into the Bearings Industry and Key Milestones

Singapore entered the bearings industry with a strategic focus on becoming a hub for high-quality manufacturing and technological innovation. The nation's journey began with early investments in infrastructure and education, laying the groundwork for a skilled workforce capable of supporting advanced manufacturing processes.

Key milestones in Singapore's bearings industry include the establishment of dedicated research institutes and partnerships with global bearing manufacturers. These collaborations facilitated technology transfer and knowledge exchange, enabling local companies to adopt state-of-the-art practices in bearing design, production, and quality control.

The government's proactive policies also played a crucial role in attracting multinational corporations to set up regional headquarters and production facilities in Singapore. This influx of expertise and investment bolstered the local bearings sector, positioning Singapore as a key player in the global supply chain for precision-engineered components.

Discuss the Initial Challenges and Breakthroughs in Sealed Bearing Technology

The development of sealed bearing technology presented initial hurdles related to seal integrity, material compatibility, and performance under extreme conditions. Engineers in Singapore and beyond tackled these challenges through systematic research and development initiatives focused on enhancing seal design, optimizing bearing materials, and refining manufacturing processes.

Breakthroughs in sealed bearing technology included innovations in seal materials such as synthetic rubbers and advanced polymers, which improved resistance to abrasion, temperature variations, and chemical exposure. Additionally, advancements in lubrication techniques, including the use of specialized greases and coatings, further enhanced bearing performance and longevity.

The cumulative effect of these innovations was not only extended maintenance intervals and reduced downtime but also expanded the application of sealed bearings into new industries such as renewable energy, medical devices, and robotics. Today, sealed bearings manufactured in Singapore are renowned for their reliability, precision, and ability to withstand the rigors of modern industrial environments.

Utilizations of Sealed Bearings in Modern Industries

Sealed bearings have revolutionized various industries by offering enhanced reliability, durability, and performance in demanding operational environments. explores their wide-ranging applications across different sectors and highlights the advantages that have propelled their adoption.

Detailed Exploration of Industries Benefiting from Sealed Bearings

Sealed bearings find extensive use in industries where precision motion control, minimal maintenance, and prolonged service life are critical factors. Their ability to operate effectively in challenging conditions such as high temperatures, corrosive environments, and heavy load applications makes them indispensable across diverse sectors.

Examples of Applications in Automotive, Aerospace, Manufacturing, etc.

|

Automotive |

Wheel hubs, transmissions, engines |

Smooth operation, reduced frictional losses, extended service intervals, improved vehicle performance and fuel efficiency |

|

Aerospace |

Aircraft landing gear, engines, flight control systems |

Withstand extreme temperatures, high speeds, harsh environments, ensure reliable performance and safety during flight operations |

|

Manufacturing |

Conveyor systems, robotics, processing equipment |

Maintain operational integrity in dusty or wet environments, enhance productivity, reduce maintenance downtime |

Advantages such as Durability, Reduced Maintenance, and Enhanced Performance

The adoption of sealed bearings offers several advantages over traditional bearings:

Durability: Integrated seals protect against contaminants, extending bearing lifespan and reducing the need for frequent replacements.

Reduced Maintenance: Sealed bearings require minimal maintenance compared to their open counterparts, translating to lower operational costs and increased uptime.

Enhanced Performance: Improved sealing technologies and materials optimize bearing performance, contributing to smoother operation and higher efficiency in industrial processes.

In Singapore, these benefits have led to widespread adoption of sealed bearings across key industries, bolstering the nation's reputation as a hub for advanced manufacturing and engineering excellence.

Innovations in Sealed Bearings by Singaporean Companies

Singaporean companies have been at the forefront of advancing sealed bearing technology, pioneering innovative approaches that enhance performance, durability, and efficiency across global industries. explores the contributions of these firms, highlighting their groundbreaking developments in seal design, materials, and market impact.

Overview of Innovative Approaches by Singaporean Firms in Bearing Technology

Singapore's strategic location and supportive business environment have fostered a thriving ecosystem for technological innovation in bearing manufacturing. Local companies have leveraged extensive research and development capabilities to introduce novel solutions that address the evolving needs of modern industries.

Innovations in Sealed Bearings by Singaporean Companies

Singaporean companies have made remarkable strides in advancing sealed bearing technology, contributing innovative solutions that redefine industry standards. Here are some exemplary companies leading the charge in seal design, materials innovation, and technological integration:

|

Company |

Innovation |

Applications |

Benefits |

|

SealTech Solutions |

High-Performance Seal Design |

Aerospace, automotive, industrial sectors |

Withstand extreme temperatures, corrosive chemicals, heavy loads; extend bearing lifespans, reduce maintenance costs |

|

MaterialTech Innovations |

Advanced Materials Science |

High-speed machinery, aerospace, automotive sectors |

Lightweight, durable materials; minimize frictional losses, improve energy efficiency |

|

TechConnect Solutions |

Integration of Smart Technologies |

Industrial automation, renewable energy |

Real-time monitoring, predictive maintenance; optimize performance, minimize downtime |

These companies exemplify Singapore's commitment to innovation and excellence in sealed bearing technology. Through continuous research and collaboration with global partners, they not only meet current industry demands but also anticipate future needs in a rapidly evolving market landscape.

Impact of Innovation on Global Markets and Technological Standards

The innovations introduced by Singaporean companies have not only strengthened their competitive edge but also set new benchmarks in global bearing technology standards. By pushing the boundaries of seal design, material science, and digital integration, these advancements have reshaped industry expectations for reliability, efficiency, and sustainability.

Singapore's role as a hub for innovation in sealed bearings is underscored by its commitment to research excellence, industry collaboration, and continuous improvement. As these innovations continue to evolve, they are poised to drive further advancements in industrial automation, renewable energy, and smart infrastructure worldwide.

Future Trends and Potential Developments in Sealed Bearings

The future of sealed bearings is poised for significant advancements, driven by emerging technologies and innovative applications. explores the predicted trends and developments that are likely to shape the landscape of sealed bearings in the coming years.

Predictions for the Future of Sealed Bearing Technology

The evolution of sealed bearing technology is expected to continue along several key trajectories. Innovations in materials science, such as the development of new composites and nanomaterials, will enhance bearing performance by reducing friction, improving durability, and enabling operation in more extreme conditions. Additionally, advancements in seal design will focus on enhancing sealing effectiveness against contaminants while maintaining operational efficiency.

Emerging Trends in Materials, Design, and Applications

|

Trend Category |

Description |

Examples of Impact |

|

Materials Advancements |

Future bearings will utilize advanced materials with superior mechanical properties and resilience. These materials enhance durability and reduce maintenance needs. |

Operate under higher loads and temperatures while maintaining dimensional stability. |

|

Design Innovations |

Bearings will prioritize compact designs and integration with digital technologies, including embedded sensors for real-time monitoring. |

Enable predictive maintenance strategies; enhance operational reliability across industries. |

|

Application Expansion |

Sealed bearings will extend beyond traditional sectors to new applications in renewable energy, medical devices, and consumer electronics. |

Support sustainable technologies; operate efficiently in diverse environmental conditions. |

Singapore's Role in Shaping the Future Landscape of Sealed Bearings

Singapore has established itself as a hub for technological innovation and advanced manufacturing capabilities. The nation's strategic investments in research and development, coupled with its robust infrastructure and skilled workforce, position it at the forefront of shaping the future of sealed bearing technology. Singaporean companies are actively involved in collaborative research projects and partnerships aimed at developing next-generation bearings that meet global market demands for efficiency, reliability, and sustainability.

Moreover, Singapore's proactive approach to integrating digital technologies and fostering a conducive environment for innovation fosters continuous improvement in bearing design and manufacturing processes. As global industries increasingly rely on high-performance bearings to enhance productivity and reduce operational costs, Singapore's contributions in materials science, precision engineering, and smart manufacturing will play a pivotal role in advancing the capabilities and applications of sealed bearings worldwide.

In conclusion, the future of sealed bearings holds promise for transformative innovations driven by advancements in materials, design, and digital integration. Singapore's proactive initiatives and technological prowess position it as a key influencer in defining the next generation of sealed bearing technologies.

Conclusion: Singapore's Continuing Influence in Sealed Bearings

Singapore has established itself as a pivotal player in the global sealed bearings industry, marked by a rich history of innovation and significant contributions to technological advancements. This section summarizes Singapore's journey, highlights its key contributions, and discusses future prospects and challenges in bearing technology.

Historical Journey and Innovation

Singapore's entry into the sealed bearings industry began with strategic investments in research and development during its industrialization phase. The country capitalized on its geographical advantage as a major shipping hub, fostering an environment conducive to technological innovation in precision engineering.

Over the decades, Singaporean companies have spearheaded advancements in seal design, materials science, and manufacturing processes. Innovations such as high-performance seals capable of withstanding extreme temperatures and corrosive environments have set new benchmarks in reliability and operational efficiency.

Global Market Impact

Singapore's innovations in sealed bearings have reverberated across global markets, influencing standards and driving improvements in various sectors. Companies like SealTech Solutions and MaterialTech Innovations have garnered international recognition for their contributions to bearing technology. Their breakthroughs have not only enhanced operational reliability but also reduced maintenance costs and extended service intervals, benefiting industries ranging from automotive to aerospace.

Future Prospects and Challenges

Looking ahead, the future of sealed bearings in Singapore remains promising yet challenging. Emerging technologies such as IoT integration and advanced materials will continue to shape the industry landscape. Singapore is poised to lead in the development of smart bearings that enable predictive maintenance and real-time performance monitoring, ensuring enhanced operational efficiency across diverse applications.

However, challenges such as global economic uncertainties and technological disruptions pose potential obstacles. Navigating these challenges will require continuous investment in research, adaptation to market dynamics, and fostering strategic collaborations with global partners.

In conclusion, Singapore's journey in sealed bearings exemplifies a commitment to innovation, quality, and resilience. As the industry evolves, Singapore's role as a center of excellence in bearing technology is set to expand, driving forward advancements that redefine operational standards and sustainability in engineering practices.

FAQs: Common Questions About Sealed Bearings

What are sealed bearings?

Sealed bearings are types of bearings that incorporate seals or shields to protect the bearing components from contamination and retain lubrication. These seals can be made from various materials such as rubber, metal, or a combination, depending on the application requirements.

How do sealed bearings differ from open bearings?

Sealed bearings differ from open bearings primarily in their design and functionality. Open bearings lack seals or shields, exposing their internal components to contaminants and requiring frequent lubrication maintenance. In contrast, sealed bearings offer enhanced protection against dirt, moisture, and other environmental factors, thereby extending their operational life and reducing maintenance needs.

What are the advantages of using sealed bearings?

The advantages of sealed bearings include:

Enhanced Protection: Seals or shields protect against contamination, extending bearing life.

Reduced Maintenance: Minimal lubrication requirements and less frequent maintenance intervals.

Improved Performance: Lower frictional losses and better operational reliability.

Versatility: Suitable for a wide range of applications across industries.

Where are sealed bearings commonly used?

Sealed bearings find extensive use across various industries, including:

Automotive: In wheel hubs, transmissions, and engines.

Aerospace: In aircraft landing gear, engines, and flight control systems.

Industrial Machinery: In conveyor systems, robotics, and manufacturing equipment.

How do sealed bearings contribute to sustainability?

Sealed bearings contribute to sustainability through:

Energy Efficiency: Reduced friction leads to lower energy consumption.

Extended Lifespan: Longer bearing life reduces material waste and resource consumption.

Maintenance Reduction: Fewer maintenance cycles mean less environmental impact from servicing operations.

What are the challenges associated with sealed bearings?

Challenges include:

Cost: Sealed bearings can be more expensive due to the added manufacturing complexity.

Design Constraints: Seals or shields may limit maximum operating speeds or temperature ranges.

Application Specificity: Choosing the right seal and bearing combination for specific environments can be critical.

How can businesses optimize the use of sealed bearings?

Businesses can optimize sealed bearing usage by:

Choosing the Right Type: Selecting bearings with seals suited to the operating environment.

Regular Maintenance: Following recommended maintenance schedules to ensure optimal performance.

Monitoring Performance: Implementing condition monitoring techniques to detect early signs of wear or malfunction.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings