Home> Bearing Technology> Breaking Boundaries: Advancements in Four-Row Cylindrical Roller Radial Bearings

1. Introduction

In the realm of mechanical engineering, Four-Row Cylindrical Roller Radial Bearings represent a pinnacle of innovation and technological advancement. These bearings, distinguished by their ability to support heavy radial loads and moderate axial loads in both directions, have undergone significant evolution over the years. With this evolution comes a profound impact on various industries, from automotive to aerospace, revolutionizing the efficiency and reliability of machinery and equipment.

The significance of advancements in Four-Row Cylindrical Roller Radial Bearings cannot be overstated. As machinery becomes more complex and demands greater precision, the role of bearings becomes increasingly crucial. Improved designs and materials in these bearings not only enhance performance but also contribute to overall safety and longevity of machinery, thereby shaping the landscape of modern industrial processes.

Exploring Leading Brands of Four-Row Cylindrical Roller Radial Bearings

Cylindrical Roller Radial Bearings in the Four-Row configuration are essential components in various industries, offering robust performance and reliability. Let's compare some leading brands to understand their key features:

|

Brand |

Key Features |

Applications |

Advantages |

Disadvantages |

|

SKF |

- Precision engineering - High load capacity - Durability |

- Heavy machinery - Steel processing - Automotive |

- Renowned for quality - Global presence - Extensive product range |

- Higher cost compared to some competitors |

|

NTN |

- Extensive product range - High-quality materials - Rigorous testing |

- Mining- Construction - Industrial machinery |

- Excellent performance - Reliability - Broad industry expertise |

- Limited presence in certain regions |

|

Timken |

- Robust construction - Long service life - Precision design |

- Steel mills - Pulp and paper - Wind energy |

- Trusted brand - Innovative solutions - Customer-centric approach |

- Relatively higher cost |

|

Schaeffler (INA/FAG) |

- Precision engineering- Versatility- Technological innovation |

- Automotive- Aerospace- Renewable energy |

- Diverse product portfolio - Strong focus on R&D- Global network |

- Some products may have longer lead times |

|

NSK |

- High-performance materials - Advanced technologies - Precision manufacturing |

- Steel mills- Mining - Construction equipment |

- Superior quality - Longevity - Extensive industry experience |

- Limited presence in certain niche markets |

2. Evolution of Four-Row Cylindrical Roller Radial Bearings

Historical Overview

The evolution of Four-Row Cylindrical Roller Radial Bearings traces back to the early developments in industrial machinery during the late 19th century. Initially, bearings were rudimentary, often crafted from basic materials such as wood or bronze. These early designs struggled to cope with the demands of heavy machinery, leading to frequent failures and inefficiencies in industrial processes.

Initial Designs and Limitations

The first-generation Four-Row Cylindrical Roller Radial Bearings featured simple configurations with limited load-bearing capacities. These bearings comprised a series of cylindrical rollers arranged in parallel rows, supported by inner and outer rings. However, their performance was hindered by factors such as inadequate lubrication systems, suboptimal materials, and inefficient sealing mechanisms.

Milestones in Advancements

The advancement of Four-Row Cylindrical Roller Radial Bearings gained momentum with breakthroughs in materials science, manufacturing technologies, and design innovations. One significant milestone was the introduction of high-quality bearing steels, such as chrome steel and stainless steel, which greatly enhanced the durability and load-bearing capacity of bearings.

Another pivotal development was the adoption of precision engineering techniques, including CNC machining and advanced surface treatments, which allowed for tighter tolerances and smoother surface finishes in bearing components. These improvements led to reduced friction, increased operational efficiency, and extended service life of Four-Row Cylindrical Roller Radial Bearings.

Furthermore, advancements in lubrication systems, such as the introduction of sealed and greased bearings, mitigated issues related to friction and wear, ensuring optimal performance even in harsh operating conditions. Additionally, innovative sealing technologies, such as labyrinth seals and contact seals, improved the ingress protection of bearings, enhancing their reliability and longevity.

In conclusion, the evolution of Four-Row Cylindrical Roller Radial Bearings has been characterized by a series of significant advancements in materials, manufacturing, and design. These innovations have not only addressed the limitations of earlier designs but also paved the way for superior performance, durability, and reliability in modern industrial applications.

3. Design Innovations

In recent years, significant design innovations have propelled the field of Four-Row Cylindrical Roller Radial Bearings to new heights, revolutionizing the way these bearings perform and function in various industrial applications.

Enhanced Load Capacity and Durability

One of the most notable advancements in Four-Row Cylindrical Roller Radial Bearings is the enhancement of load capacity and durability. Engineers and researchers have developed innovative bearing configurations and materials to withstand higher radial and axial loads, ensuring optimal performance even in the most demanding operating conditions.

Advanced materials such as high-strength bearing steels, ceramic hybrids, and polymer composites have been employed to increase the strength and resilience of bearing components. These materials exhibit superior wear resistance, fatigue strength, and corrosion resistance, prolonging the service life of Four-Row Cylindrical Roller Radial Bearings and minimizing the risk of premature failure.

Moreover, novel bearing designs, including optimized roller profiles, cage geometries, and raceway treatments, have been introduced to distribute loads more evenly across the bearing surfaces. This results in reduced stress concentrations and improved load-carrying capabilities, enabling Four-Row Cylindrical Roller Radial Bearings to handle higher loads with greater efficiency and reliability.

Improved Sealing Mechanisms

Another area of design innovation in Four-Row Cylindrical Roller Radial Bearings revolves around sealing mechanisms. Effective sealing is essential for preventing contamination ingress, retaining lubricants, and maintaining bearing integrity in harsh operating environments.

Recent advancements in sealing technology have led to the development of robust sealing solutions that offer superior protection against contaminants such as dust, moisture, and particulate matter. These seals utilize innovative materials and designs, such as lip seals, labyrinth seals, and magnetic seals, to create a barrier between the bearing interior and the external environment.

Furthermore, integrated sensor systems and condition monitoring technologies have been integrated into sealing assemblies to provide real-time feedback on bearing health and performance. This proactive approach to maintenance allows operators to identify potential issues early, minimizing downtime and optimizing equipment reliability.

Precision Engineering Techniques

Precision engineering techniques play a pivotal role in the design and manufacturing of Four-Row Cylindrical Roller Radial Bearings. Advanced machining processes, such as computer numerical control (CNC) machining, honing, and grinding, enable the production of bearing components with tight tolerances and surface finishes.

Furthermore, finite element analysis (FEA) and computer-aided design (CAD) software facilitate the optimization of bearing geometries and performance characteristics. Engineers can simulate various operating conditions and scenarios to fine-tune bearing designs for optimal efficiency and reliability.

In conclusion, design innovations in Four-Row Cylindrical Roller Radial Bearings have ushered in a new era of performance and reliability in industrial applications. Enhanced load capacity, improved sealing mechanisms, and precision engineering techniques have collectively contributed to the advancement of these bearings, breaking boundaries and setting new standards for excellence in mechanical engineering.

4. Applications Across Industries

The advancements in Four-Row Cylindrical Roller Radial Bearings have paved the way for their widespread adoption across various industries, where these bearings play a crucial role in ensuring the smooth operation and reliability of critical machinery and equipment.

|

Automotive Sector |

In the automotive sector, Four-Row Cylindrical Roller Radial Bearings are utilized in a multitude of applications, ranging from vehicle transmissions and wheel hubs to engine components and steering systems. These bearings are engineered to withstand high radial and axial loads, providing support and stability in demanding driving conditions. Furthermore, their precision engineering and enhanced load-carrying capabilities contribute to the overall performance and safety of vehicles on the road. |

|

Heavy Machinery and Equipment |

Heavy machinery and equipment, such as construction machinery, mining equipment, and material handling systems, rely heavily on Four-Row Cylindrical Roller Radial Bearings to facilitate smooth and efficient operation. These bearings are employed in various components, including gearboxes, shafts, and rollers, where they endure heavy loads and harsh operating environments. Their robust construction and superior load capacity make them indispensable for maintaining uptime and productivity in heavy-duty applications. |

|

Aerospace Industry |

The aerospace industry demands precision, reliability, and lightweight solutions, making Four-Row Cylindrical Roller Radial Bearings an ideal choice for critical aerospace applications. These bearings are utilized in aircraft engines, landing gear systems, and flight control mechanisms, where they provide essential support and motion control. The stringent performance requirements of the aerospace sector necessitate bearings that can withstand extreme temperatures, high speeds, and rigorous conditions, making Four-Row Cylindrical Roller Radial Bearings the preferred choice for aerospace engineers and manufacturers. |

|

Wind Turbines and Renewable Energy |

In the field of renewable energy, particularly wind power generation, Four-Row Cylindrical Roller Radial Bearings play a vital role in the operation and performance of wind turbines. These bearings are employed in the main shafts and gearbox assemblies of wind turbines, where they endure high rotational speeds and dynamic loads. By providing reliable support and minimizing frictional losses, these bearings contribute to the efficiency and sustainability of wind energy production, helping to meet the growing demand for clean and renewable power sources. |

In summary, Four-Row Cylindrical Roller Radial Bearings find applications across a diverse range of industries, including automotive, heavy machinery, aerospace, and renewable energy. Their versatility, durability, and precision engineering make them indispensable components in critical machinery and equipment, driving advancements and innovation in various sectors.

5. Performance Characteristics

The performance characteristics of Four-Row Cylindrical Roller Radial Bearings are key factors that contribute to their widespread adoption and utilization across various industries. Let's delve into the essential performance attributes of these bearings:

|

High-Speed Capability |

Four-Row Cylindrical Roller Radial Bearings are engineered to deliver exceptional high-speed performance, making them ideal for applications where rotational speeds are critical. With advancements in materials and design, these bearings can withstand rotational speeds ranging from moderate to extremely high, ensuring smooth operation and minimal frictional losses. Their ability to maintain stability and reliability at elevated speeds makes them indispensable components in machinery and equipment operating in dynamic environments. |

|

Load Distribution Efficiency |

Efficient load distribution is a hallmark of Four-Row Cylindrical Roller Radial Bearings, enabling them to support heavy radial and axial loads with ease. These bearings utilize multiple rows of cylindrical rollers arranged in parallel, along with precision-engineered raceways and cage designs, to evenly distribute loads across the bearing surfaces. This uniform distribution of loads minimizes stress concentrations and prevents premature wear and fatigue, ensuring prolonged service life and reliability in demanding applications. |

|

Temperature Resistance |

Temperature resistance is another critical performance characteristic of Four-Row Cylindrical Roller Radial Bearings, particularly in applications where high temperatures are prevalent. These bearings are designed to operate effectively across a wide range of temperatures, from sub-zero conditions to extreme heat. Advanced materials and lubricants, combined with innovative sealing technologies, enable Four-Row Cylindrical Roller Radial Bearings to withstand thermal fluctuations without compromising their performance or integrity. This temperature resistance ensures consistent operation and longevity, even in challenging operating environments. |

In conclusion, the performance characteristics of Four-Row Cylindrical Roller Radial Bearings encompass high-speed capability, efficient load distribution, and temperature resistance. These attributes make them indispensable components in various industrial applications, where reliability, durability, and precision are paramount. As advancements in materials, design, and manufacturing continue to push the boundaries of engineering innovation, Four-Row Cylindrical Roller Radial Bearings will continue to play a pivotal role in shaping the future of mechanical systems and equipment.

6. Conclusion

In conclusion, the advancements in Four-Row Cylindrical Roller Radial Bearings represent a significant leap forward in mechanical engineering, breaking boundaries and opening new possibilities in various industrial applications. Throughout this article, we have explored the evolution, design innovations, applications across industries, performance characteristics, challenges, and future directions of these bearings.

Summary of Key Advancements:

The evolution of Four-Row Cylindrical Roller Radial Bearings has been marked by significant advancements in materials, design, and manufacturing techniques. These advancements have resulted in bearings with enhanced load capacity, improved sealing mechanisms, and superior performance characteristics such as high-speed capability, efficient load distribution, and temperature resistance.

Future Prospects in Four-Row Cylindrical Roller Radial Bearings:

Looking ahead, the future of Four-Row Cylindrical Roller Radial Bearings is promising, with opportunities for further innovation and integration with emerging technologies. Addressing challenges such as lubrication issues, environmental sustainability, and technology integration will be critical in unlocking the full potential of these bearings. By embracing these challenges and exploring new frontiers, the industry can continue to advance the field of mechanical engineering and drive progress in industrial applications.

In summary, the advancements in Four-Row Cylindrical Roller Radial Bearings have not only transformed the way machinery and equipment operate but also laid the foundation for a more efficient, reliable, and sustainable future. As we continue to push the boundaries of engineering innovation, Four-Row Cylindrical Roller Radial Bearings will remain at the forefront of technological advancements, shaping the landscape of industrial processes and driving progress across various industries.

7. FAQs: Common Questions About Cylindrical Roller Radial Bearings/Four-Row

1. What are Four-Row Cylindrical Roller Radial Bearings?

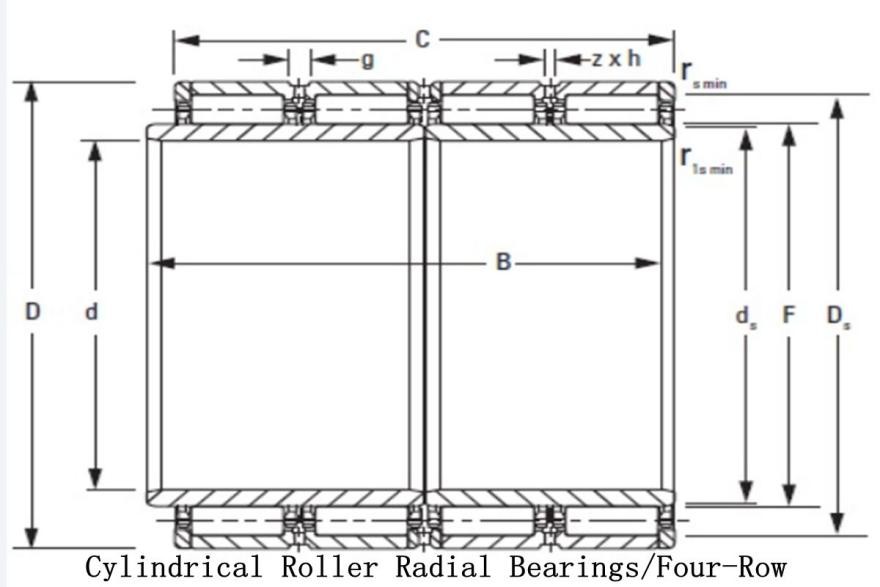

Four-Row Cylindrical Roller Radial Bearings are precision-engineered mechanical components designed to support heavy radial loads and moderate axial loads in both directions. As the name suggests, these bearings consist of four rows of cylindrical rollers, each guided by inner and outer rings. This configuration allows for enhanced load-carrying capacity and improved stability, making them suitable for applications where high load capacity and reliability are essential.

2. How do Four-Row Cylindrical Roller Radial Bearings compare to other bearing types?

Compared to other bearing types, such as single-row or double-row cylindrical roller bearings, Four-Row Cylindrical Roller Radial Bearings offer superior load-carrying capacity and rigidity. Their multi-row design enables them to handle heavier loads and provide greater stability, particularly in applications with high radial and axial loads. Additionally, the four-row configuration allows for smoother operation and reduced friction, enhancing efficiency and minimizing energy consumption.

3.What are the maintenance requirements for Four-Row Cylindrical Roller Radial Bearings?

Proper maintenance is essential for ensuring the optimal performance and longevity of Four-Row Cylindrical Roller Radial Bearings. Regular lubrication with high-quality lubricants is necessary to reduce friction and prevent premature wear. Additionally, periodic inspections for signs of wear, misalignment, or contamination are recommended to detect potential issues early and avoid costly downtime. Proper handling, storage, and installation practices are also crucial to maximizing the service life of these bearings.

4. Are there any specialized considerations when selecting Four-Row Cylindrical Roller Radial Bearings?

When selecting Four-Row Cylindrical Roller Radial Bearings, several factors must be considered, including load requirements, operating conditions, speed, and environmental factors. It's essential to choose bearings with the appropriate load ratings, clearance, and sealing arrangements to ensure optimal performance and reliability in specific applications. Collaborating with experienced bearing suppliers and engineers can help identify the best bearing solution tailored to the unique requirements of each application.

5. How do advancements in Four-Row Cylindrical Roller Radial Bearings contribute to industrial progress?

Advancements in Four-Row Cylindrical Roller Radial Bearings drive industrial progress by improving efficiency, reliability, and sustainability in various applications. Enhanced load capacity, improved sealing mechanisms, and advanced materials enable these bearings to withstand higher loads, operate at higher speeds, and endure harsh environmental conditions. By providing reliable motion control and minimizing downtime, these bearings play a crucial role in optimizing industrial processes and driving innovation across industries.

In summary, Four-Row Cylindrical Roller Radial Bearings offer exceptional performance, reliability, and versatility, making them indispensable components in a wide range of industrial applications. Understanding their design, advantages, applications, and maintenance requirements is essential for maximizing their benefits and ensuring optimal performance in critical machinery and equipment.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings