Home> Bearing Technology> Precision in Motion: Navigating the Advancements of High-Speed Deep Groove Ball Bearings 6307-2rz

Precision in Motion: Navigating the Advancements of High-Speed Deep Groove Ball Bearings 6307-2rz

NOVEMBER 02, 2022Introduction

In the dynamic landscape of industrial machinery, the role of bearings is pivotal, with high-speed deep groove ball bearings emerging as a cornerstone for precision and efficiency.

High-speed bearings are instrumental in various industries, ensuring the seamless operation of machinery with optimal efficiency. As we delve into the nuances of these bearings, our spotlight turns to the remarkable strides made in the development of 6307-2rz bearings, highlighting their significance in the broader landscape of precision motion control.

Technical Evolution

In the ever-evolving landscape of high-speed deep groove ball bearings, the journey of technical evolution unfolds with precision and innovation. delves into the intricate details of the advancements that characterize High-Speed Deep Groove Ball Precision Motor Bearings, with a keen focus on the exceptional 6307-2rz bearings.

Engineering Marvels

Design Innovations

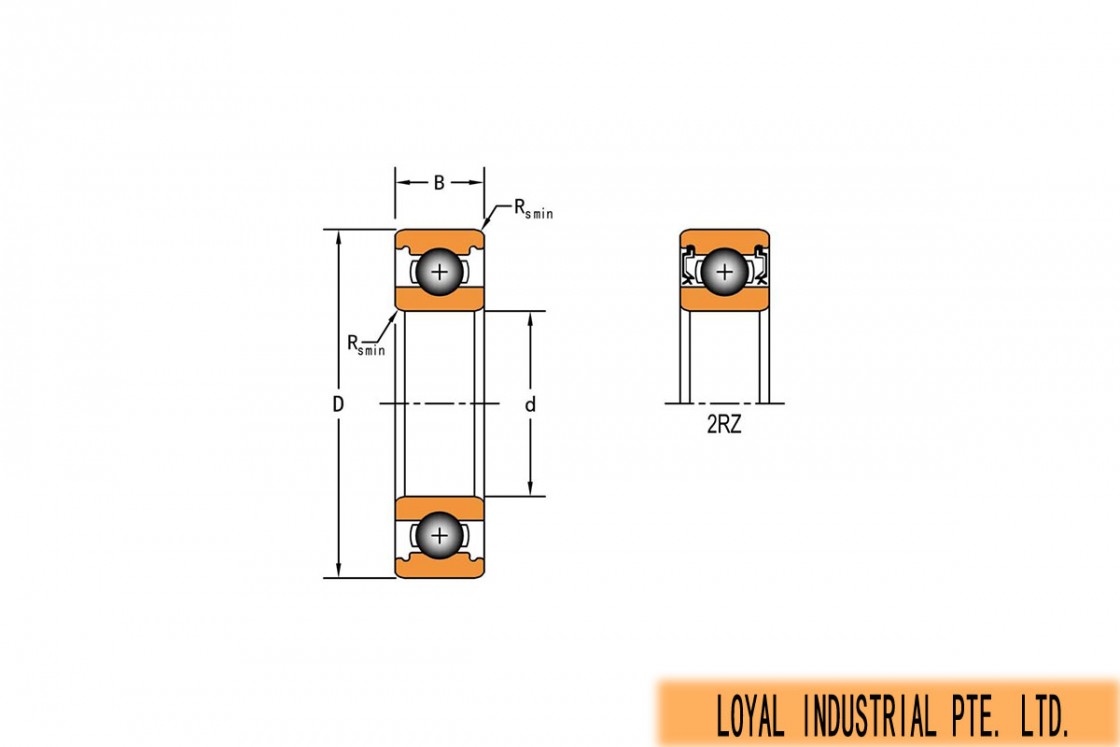

The evolution of 6307-2rz bearings is marked by groundbreaking design innovations. The precision in motion begins with the intricately crafted design elements that set these bearings apart from their counterparts. Our exploration encompasses the structural intricacies, such as the arrangement of balls and raceways, which contribute to the superior performance of these bearings.

Material Selection

A critical aspect of the technical evolution lies in the meticulous selection of materials. The 6307-2rz bearings showcase a marriage of advanced alloys, ensuring durability and resilience under high-speed conditions. navigates through the metallurgical intricacies, shedding light on how material advancements contribute to the bearings' longevity and performance.

Precision Engineering

Manufacturing Processes

The evolution of high-speed bearings is intricately tied to advancements in manufacturing processes. Our exploration extends to the sophisticated techniques employed in crafting 6307-2rz bearings. From precision machining to cutting-edge assembly methods, we unravel the manufacturing prowess that defines these bearings' technical evolution.

Lubrication Strategies

An essential facet of the technical evolution lies in the optimization of lubrication strategies. The 6307-2rz bearings exhibit a meticulous approach to lubricant selection and distribution, ensuring minimal friction and maximal efficiency. This segment offers insights into the lubrication advancements that contribute to the precision motion achieved by these bearings.

Through the technological evolution of high speed deep groove ball precision motor bearings, the design and engineering miracle that put 6307-2rz bearings at the forefront of motion accuracy is described.

Performance Insights

In the dynamic world of high-speed deep groove ball bearings, the quest for precision in motion goes hand in hand with a relentless pursuit of superior performance. meticulously explores the performance insights encapsulated in High-Speed Deep Groove Ball Precision Motor Bearings, with a primary focus on the remarkable 6307-2rz bearings.

Speed Unleashed

Velocity Dynamics

At the heart of the performance paradigm lies the exceptional speed capabilities of 6307-2rz bearings. Delving into the velocity dynamics, we unravel the intricacies that enable these bearings to operate seamlessly under high-speed conditions. The optimized ball and raceway design work in tandem to minimize friction, allowing for swift and precise motion.

Acceleration Tolerance

Performance is not merely about maintaining high speeds but also about the bearings' ability to tolerate rapid accelerations. This segment explores the engineering nuances that empower 6307-2rz bearings to withstand varying acceleration forces, ensuring a consistent and reliable performance profile.

Precision Personified

Angular Contact Precision

Precision motor applications demand an unparalleled level of accuracy. The 6307-2rz bearings excel in providing angular contact precision, ensuring that rotational movements are executed with the utmost accuracy. This part of our exploration sheds light on how these bearings achieve and maintain precision in the most demanding applications.

Durability Under Load

Performance insights extend to the bearings' durability under heavy loads. Real-world examples will be dissected to illustrate how 6307-2rz bearings outshine others in challenging environments, showcasing their robust construction and load-bearing capabilities.

Real-World Performance Showcases

|

Automotive Industry |

We present a case study on the application of 6307-2rz bearings in the automotive industry, emphasizing the enhanced performance and longevity observed in critical motor components. |

|

Industrial Machinery |

Examining their role in industrial machinery, we showcase instances where 6307-2rz bearings have elevated the performance standards, contributing to the efficiency and reliability of various machinery. |

Applications Across Industries

In the realm of precision engineering, the advancements in High-Speed Deep Groove Ball Precision Motor Bearings, particularly the 6307-2rz model, have transcended the boundaries of industries. delves into the widespread applications where these bearings have become instrumental, showcasing their versatility and indispensable role.

Unveiling the Multifaceted Applicability

Automotive Precision

One of the prime sectors reaping the benefits of 6307-2rz bearings is the automotive industry. The bearings find application in critical components like engine assemblies and transmission systems. We explore how the precision and high-speed capabilities of these bearings contribute to the efficiency and performance of modern vehicles.

Aerospace Advancements

In the aerospace sector, where precision is non-negotiable, 6307-2rz bearings have emerged as a cornerstone. From flight control systems to navigation equipment, we scrutinize how these bearings elevate the standards of precision, ensuring reliability in the most demanding conditions.

Industrial Machinery Excellence

From conveyor systems to robotic arms, the industrial machinery sector witnesses a profound impact with the integration of 6307-2rz bearings. Real-world examples will illuminate instances where these bearings enhance the operational efficiency and lifespan of various machinery components.

Renewable Energy Applications

As the world embraces renewable energy sources, the bearings' role in wind turbines and solar tracking systems becomes pivotal. This segment explores how 6307-2rz bearings contribute to the smooth operation and longevity of components in the renewable energy sector.

Real-World Showcases

Case Study: Automotive Assembly Line

A detailed case study highlights a scenario in an automotive assembly line, emphasizing the role of 6307-2rz bearings in ensuring precision and reliability in conveyor systems and robotic arms.

Aerospace Navigation Systems

We showcase an instance in the aerospace industry, illustrating how 6307-2rz bearings play a critical role in the precision of navigation systems, ensuring accuracy in flight control.

we gain a comprehensive understanding of how 6307-2rz bearings have become indispensable across various industries. Their adaptability, precision, and high-speed capabilities make them a cornerstone in the machinery that propels our modern world forward.

|

|

Material |

Sealing Mechanism |

Load Capacity |

Speed Rating |

Applications |

Notable Features |

|

SKF |

Stainless Steel |

Non-contact seals (2rz) |

High radial and axial loads |

High-speed performance |

Precision Motors, Industrial Machinery |

- Advanced material for enhanced durability |

|

FAG |

Chrome Steel |

Contact seals (2rs) |

Balanced radial and axial loads |

Moderate-speed capabilities |

Automotive, General Machinery |

- Affordable option with standard features |

|

NSK |

Hybrid Ceramic (Steel Rings) |

Non-contact seals (2rz) |

High radial loads |

Very high-speed performance |

Electric Motors, Precision Instruments |

- Reduced friction for improved efficiency |

|

NTN |

Carbon Steel with Heat Treatment |

Non-contact seals (2rz) |

High axial loads |

High-speed capabilities |

Heavy Machinery, Agriculture Equipment |

- Specially treated for heat resistance |

Testing and Validation

In the realm of High-Speed Deep Groove Ball Precision Motor Bearings, the importance of rigorous testing and validation cannot be overstated. delves into the meticulous processes employed to ensure the performance, reliability, and durability of 6307-2rz bearings, shedding light on the methodologies and presenting tangible data that underscores their precision.

Understanding the Testing Landscape

Methodologies Employed

We embark on an exploration of the various testing methodologies that manufacturers employ to scrutinize 6307-2rz bearings. This includes but is not limited to:

|

Rotational Testing |

Bold exploration into how rotational tests assess the bearings' performance under high-speed conditions. - Key parameters examined include rotational speed, torque, and temperature. |

|

Load Capacity Analysis |

- A deep dive into load capacity testing, evaluating how 6307-2rz bearings handle axial and radial loads. - Bold insights into the load-bearing capabilities that contribute to their reliability in diverse applications. |

|

Endurance Testing |

- Exploration of endurance tests that simulate prolonged operating conditions. - Real-world scenarios are replicated to ensure the bearings' longevity and resilience. |

|

Sealing Integrity Checks |

- Discussion on how tests assess the effectiveness of seals, crucial for preventing contamination and ensuring optimal performance. |

Presenting Results and Data

Efficiency Metrics

An emphasis on the efficiency metrics derived from testing, including:

Frictional Characteristics

- Bold insights into the frictional characteristics under varying conditions.

- Data presentation highlighting how low friction contributes to energy efficiency.

Temperature Tolerance

- Exploration of the temperature tolerance data, showcasing how 6307-2rz bearings maintain optimal performance across a spectrum of temperatures.

Durability Metrics

An examination of durability metrics that highlight the robust nature of these precision components:

Wear and Tear Analysis

- In-depth analysis of wear and tear patterns to gauge the bearings' durability over extended usage.

- Presentation of data reflecting minimal wear, ensuring prolonged lifespan.

Corrosion Resistance Evaluation

- Discussion on how corrosion resistance is validated through testing.

- Data presentation emphasizing the bearings' ability to withstand challenging environmental conditions.

Synthesizing the Insights

the overarching theme is the robust validation and testing processes that affirm the superiority of 6307-2rz bearings. The presented data serves not just as a testament to their efficiency and durability but also as a guide for industries seeking precision components that withstand the rigors of high-speed applications.

Future Trends and Innovations

In the ever-evolving landscape of high-speed deep groove ball bearings, anticipating future trends and innovations is paramount. embarks on a journey into the possible developments that may shape the field, offering insights into the technological advancements and innovative approaches that could redefine the role of bearings in various industries.

Navigating Emerging Technologies

Material Science Advancements

- Bold Exploration: A bold exploration into how advancements in material science may lead to the development of novel materials with enhanced durability and performance.

High-performance bearing materials, advanced alloys.

Smart Bearings Integration

- Smart Technology Integration: A discussion on the integration of smart technologies into bearings, enabling real-time monitoring and data analytics.

IoT-enabled bearings, predictive maintenance in bearings.

Nanotechnology in Bearing Design

- Nano-Innovation: An overview of how nanotechnology might revolutionize bearing design, optimizing friction, and enhancing overall efficiency.

Nanomaterials in bearings, precision at the nanoscale.

Industry-Specific Evolution

Automotive Sector Transformations

- Electric Vehicle Integration: Exploration of how the rise of electric vehicles may influence the design and demand for high-speed bearings.

Bearings in EVs, high-speed ball bearings in automotive.

Aerospace Engineering

- Lightweight Bearing Solutions: Discussion on the demand for lightweight yet high-performance bearings in aerospace applications.

Aerospace bearings, lightweight high-speed bearings.

Predictions and Industry Adaptations

Predictive Maintenance Standardization

- Industry Evolution: Predictions on how predictive maintenance may become a standard practice, minimizing downtime and maximizing efficiency.

- : Industry 4.0 in bearings, predictive maintenance standards.

Customization and Tailored Solutions

- Diverse Applications: Insights into how the industry may shift towards providing customized bearing solutions to meet diverse application needs.

- : Tailored bearing solutions, customized bearing design.

Synthesizing Future Possibilities

In conclusion, this exploration of future trends and innovations presents a glimpse into the exciting possibilities that lie ahead for high-speed deep groove ball bearings. As technology advances and industries continue to evolve, embracing these innovations will not only define the future of bearings but also reshape the way we perceive precision components in the broader context of industrial machinery and automation.

FAQs: Common Questions About 6307-2rz Bearings

Introduction:

High-Speed Deep Groove Ball Precision Motor Bearings, specifically the 6307-2rz variant, play a crucial role in various industrial applications where precision, speed, and reliability are paramount. we will address common questions related to the features, applications, and benefits of 6307-2rz bearings, providing valuable insights for users and professionals in the field of bearings and precision engineering.

What are 6307-2rz Bearings and How Do They Differ from Other Bearings?

- Definition: 6307-2rz bearings are high-speed deep groove ball bearings designed with precision engineering to deliver exceptional performance in motor applications.

- Distinguishing Features: These bearings are distinguished by their advanced design, optimized lubrication, and enhanced materials, ensuring superior speed, precision, and durability compared to standard bearings.

What Are the Key Features and Benefits of 6307-2rz Bearings?

- Enhanced Performance: 6307-2rz bearings offer high-speed capabilities, reduced friction, and improved precision, resulting in enhanced motor performance, energy efficiency, and extended service life.

- Reliability: With their robust construction and advanced engineering, 6307-2rz bearings provide reliable operation even in demanding industrial environments, minimizing downtime and maintenance costs.

What Industries Utilize 6307-2rz Bearings?

- Automotive: These bearings are widely used in automotive applications, including electric vehicle drivetrains, engine components, and transmission systems, where high-speed operation and precision are essential.

- Aerospace: In the aerospace industry, 6307-2rz bearings find applications in aircraft engines, landing gear systems, and flight control mechanisms, where reliability and performance are critical for safety and efficiency.

How Do Users Ensure Proper Installation and Maintenance of 6307-2rz Bearings?

- Installation Guidelines: Users must follow manufacturer-recommended installation procedures, including proper alignment, mounting, and lubrication, to ensure optimal performance and longevity of 6307-2rz bearings.

- Maintenance Practices: Regular inspection, lubrication, and monitoring of operating conditions are essential to prevent premature wear and ensure the continued reliability and performance of these precision bearings.

What Are the Environmental Considerations for 6307-2rz Bearings?

- Temperature and Contamination: Proper environmental conditions, including temperature control and contamination prevention, are crucial for maintaining the performance and reliability of 6307-2rz bearings in industrial settings.

- Sealing Options: Various sealing options are available for 6307-2rz bearings to protect against dust, debris, and moisture ingress, ensuring long-term performance in diverse operating environments.

Can 6307-2rz Bearings Be Customized for Specific Applications?

- Customization Options: Manufacturers offer customization services to tailor 6307-2rz bearings to specific application requirements, including material selection, lubrication type, and sealing options, ensuring optimal performance and compatibility with various industrial applications.

Conclusion:

In conclusion, 6307-2rz bearings represent a significant advancement in high-speed deep groove ball bearing technology, offering unparalleled performance, precision, and reliability in precision motor applications.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings