Home> Bearing Technology> 6203rsc3 Bearing Brilliance: Unraveling the Engineering Marvel

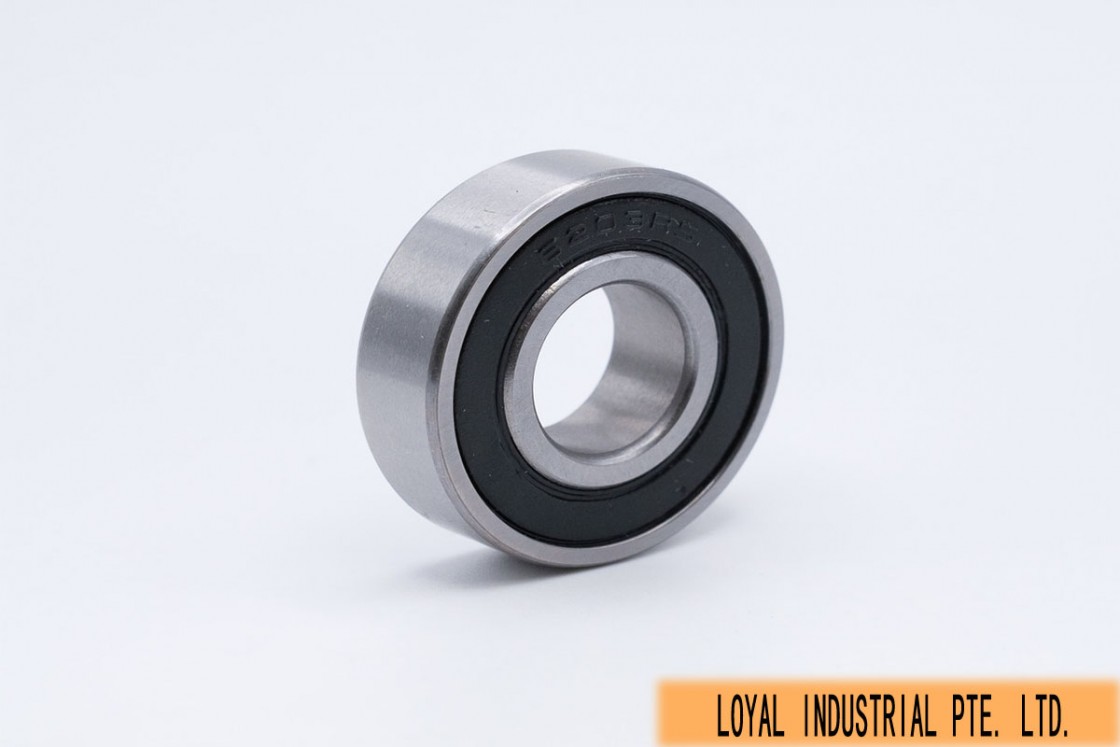

In the vast landscape of industrial machinery and precision applications, the significance of high-quality bearings cannot be overstated. our focus turns to the engineering marvel that is the 6203-RSC3 bearing. This deep groove radial ball bearing stands out as a beacon of brilliance, promising unparalleled performance and reliability in a variety of settings.

Understanding the intricacies of the 6203-RSC3 bearing involves delving into its design, specifications, and the engineering innovations that set it apart. In this exploration, we aim to unravel the brilliance encapsulated within this bearing, shedding light on its capabilities and the transformative impact it has on diverse industries.

Whether it's the seamless operation of industrial machinery, the precision required in automotive applications, or the efficiency demanded by electric motors, the 6203-RSC3 bearing emerges as a critical component.

Understanding 6203-RSC3 Bearing

In our quest to unravel the engineering marvel that is the 6203-RSC3 bearing, it's imperative to dive deep into its specifications and design intricacies. provide a comprehensive understanding of the key features that make the 6203-RSC3 stand out in the realm of deep groove radial ball bearings.

|

Specification Overview |

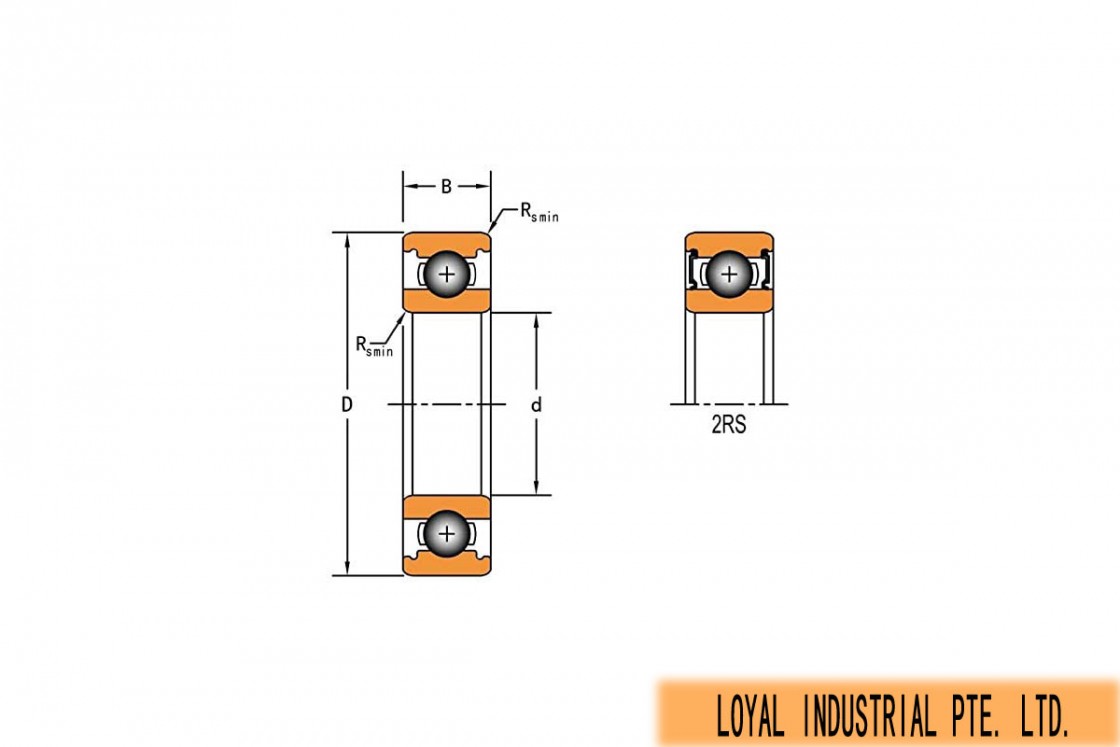

The 6203-RSC3 bearing belongs to the category of deep groove radial ball bearings, renowned for its versatility and performance across various applications. Its nomenclature provides insights into its specifications, with "6203" indicating the bearing series and size, and "RSC3" specifying its sealing mechanism and internal clearance. |

|

Design Intricacies |

The brilliance of the 6203-RSC3 bearing lies in its meticulous design. Crafted with precision, the bearing features a deep groove design, allowing it to accommodate radial and axial loads with remarkable efficiency. The internal components, such as the ball retainer and raceways, are engineered to perfection, ensuring smooth operation and reduced friction. |

|

Sealing Mechanism |

One of the defining characteristics of the 6203-RSC3 is its sealing mechanism. The "RSC3" designation signifies a particular type of seal that provides an additional layer of protection against contaminants. This non-contact seal minimizes friction, enhances durability, and extends the bearing's lifespan. |

|

Enhanced Capabilities |

The 6203-RSC3 excels in its deep groove radial ball bearing capabilities. Its ability to handle both radial and axial loads makes it a versatile choice across industries. Whether in electric motors, agricultural machinery, or automotive applications, this bearing delivers consistent and reliable performance. |

Advantages and Applications

In the exploration of the engineering marvel encapsulated in the 6203-RSC3 bearing, it's crucial to uncover the distinct advantages that set this bearing apart. highlighting real-world applications across diverse industries where their brilliance truly shines.

Advantages of 6203-RSC3 Bearings:

Superior Load Capacity:

- 6203-RSC3 bearings, with their deep groove design and precision engineering, exhibit superior load-bearing capabilities. The design enables them to handle both radial and axial loads with remarkable efficiency, ensuring stability and reliability in various applications.

Enhanced Durability:

- The non-contact sealing mechanism of the 6203-RSC3 bearing plays a pivotal role in enhancing its durability. The "RSC3" designation signifies a sealing mechanism that minimizes friction, reduces wear and tear, and extends the lifespan of the bearing, making it a reliable choice for prolonged usage.

Versatility Across Industries:

- One of the key advantages of the 6203-RSC3 bearing lies in its versatility. It finds applications across a spectrum of industries, including but not limited to electric motors, agricultural machinery, and automotive systems. This versatility stems from its ability to perform optimally in diverse operational conditions.

Smooth and Quiet Operation:

- Precision in design ensures that 6203-RSC3 bearings operate smoothly and quietly. This attribute is particularly crucial in applications where noise reduction is essential, such as in precision instruments and certain automotive components.

Real-World Applications:

Electric Motors:

- The 6203-RSC3 bearing is a preferred choice in electric motors due to its ability to handle high-speed rotations with minimal friction. This makes it an integral component in various electric motor applications across industries.

Agricultural Machinery:

- In the agricultural sector, where machinery faces challenging working conditions, the durability and load-bearing capacity of the 6203-RSC3 bearing make it an ideal choice. It ensures reliable performance in farm equipment and machinery.

Automotive Systems:

- Automotive applications benefit from the versatility of 6203-RSC3 bearings, whether in wheel assemblies, transmissions, or other components. Their ability to handle diverse loads and conditions makes them indispensable in the automotive industry.

Unveiling the advantages and applications of 6203-RSC3 bearings provides a comprehensive understanding of their significance in various industries.

Technological Innovations

In the world of bearings, technological advancements play a pivotal role in enhancing performance, durability, and overall efficiency. into the cutting-edge technologies integrated into 6203-RSC3 bearings and discusses how these innovations contribute to their brilliance as an engineering marvel in the realm of deep groove radial ball bearings.

Cutting-Edge Technologies in 6203-RSC3 Bearings:

Advanced Material Composition:

- The 6203-RSC3 bearing incorporates advanced materials in its construction, ensuring optimal performance and durability. These materials undergo rigorous testing and selection processes to meet the demanding requirements of various applications. From high-grade stainless steel to specialized alloys, the material composition of the bearing is tailored to withstand diverse operating conditions.

Precision Engineering and Manufacturing:

- Precision engineering techniques are employed in the design and manufacturing processes of 6203-RSC3 bearings. Computer-aided design (CAD) software enables engineers to optimize the bearing's geometry for maximum efficiency and load-bearing capacity. Advanced manufacturing technologies, such as CNC machining and automated quality control systems, ensure consistent and reliable performance across production batches.

Sealing Mechanisms:

- The sealing mechanism of 6203-RSC3 bearings is a critical area of innovation. Advanced sealing technologies, including non-contact seals and labyrinth seals, are employed to prevent contamination and retain lubrication within the bearing. These seals are meticulously designed to minimize frictional losses while maximizing protection against external elements, thereby enhancing the bearing's longevity.

Lubrication Systems:

- Lubrication is essential for the smooth operation and longevity of bearings. In 6203-RSC3 bearings, advanced lubrication systems are employed to ensure optimal performance under varying operating conditions. From grease lubrication to oil bath systems, these innovative solutions are tailored to the specific requirements of each application, providing superior lubrication and extending the bearing's service life.

Enhanced Performance and Longevity:

The integration of these cutting-edge technologies into 6203-RSC3 bearings results in unparalleled performance and longevity. By leveraging advanced materials, precision engineering, innovative sealing mechanisms, and optimized lubrication systems, these bearings exhibit exceptional load-bearing capacity, reduced friction, and extended service intervals. Whether in automotive applications, industrial machinery, or precision instruments, the technological innovations embodied in 6203-RSC3 bearings redefine the standards of excellence in the field of deep groove radial ball bearings.

|

Brand |

Quality |

Reliability |

Durability |

|

SKF |

SKF bearings are renowned for their high-quality construction and precision engineering, ensuring consistent performance in various industrial applications. |

SKF bearings are highly reliable, offering stable operation and extended service life even in demanding conditions. |

SKF bearings are durable, capable of withstanding heavy loads and harsh environments, ensuring long-term reliability and productivity. |

|

NSK |

NSK bearings are known for their exceptional quality, manufactured using advanced materials and manufacturing techniques to deliver consistent performance. |

NSK bearings are highly reliable, providing dependable operation and longevity in diverse industrial environments. |

NSK bearings are durable, designed to withstand heavy loads, shock, and vibration, ensuring reliable performance over an extended service life. |

|

NTN |

NTN bearings are recognized for their superior quality, backed by stringent quality control measures to ensure precision and reliability in every bearing produced. |

NTN bearings are renowned for their reliability, offering stable performance and consistent operation in various industrial applications. |

NTN bearings are durable, engineered to withstand heavy loads, high speeds, and harsh operating conditions, ensuring long-lasting performance and reliability. |

|

FAG |

FAG bearings are known for their high-quality construction and precision engineering, providing reliable performance and superior load-carrying capacity. |

FAG bearings are highly reliable, delivering consistent operation and performance, even in challenging environments and applications. |

FAG bearings are durable, capable of withstanding heavy loads, shock, and vibration, ensuring reliable operation and extended service life. |

|

Timken |

Timken bearings are distinguished by their rugged construction, precision engineering, and exceptional load-bearing capacity, ensuring reliable performance. |

Timken bearings are highly reliable, offering dependable operation and consistent performance in various industrial and automotive applications. |

Timken bearings are durable, designed to endure heavy loads, extreme temperatures, and harsh operating conditions, ensuring long-term reliability and productivity. |

Performance Analysis

In the realm of Deep Groove Radial Ball Bearings, the 6203-RSC3 bearing stands out as an engineering marvel, and its brilliance becomes particularly evident when delving into a comprehensive performance analysis. will meticulously examine the key performance metrics, shedding light on its load capacity, speed rating, and real-world applications.

Load Capacity: Unraveling Strength Under Pressure

One of the defining features of 6203-RSC3 bearings is their impressive load capacity. _Load capacity_ signifies the maximum axial and radial loads a bearing can withstand without compromising its functionality. The 6203-RSC3 bearing, with its robust design and advanced materials, excels in handling high radial and axial loads. This attribute makes it a preferred choice for applications demanding durability and reliability under varying pressures.

Speed Rating: Precision in Motion

The brilliance of the 6203-RSC3 bearing is further underscored by its exceptional _speed rating_. This metric denotes the maximum rotational speed at which the bearing can operate effectively without causing excessive friction or heat. The design intricacies of the 6203-RSC3, coupled with advanced technologies, contribute to its high-speed performance. Precision motors and industrial machinery benefit significantly from the seamless motion facilitated by these bearings.

Empirical Data and Case Studies

To substantiate the claims of brilliance, it's imperative to turn to empirical data and real-world case studies. Numerous experiments and practical applications showcase the superior performance of 6203-RSC3 bearings. ranging from automotive to heavy machinery, will be presented, highlighting instances where the bearing's brilliance translated into enhanced efficiency and extended lifespan.

Conclusion: Brilliance in Every Rotation

As we conclude the performance analysis, the overarching theme becomes clear – the 6203-RSC3 bearing encapsulates brilliance in every rotation. Its ability to seamlessly balance high loads while maintaining precision in motion positions it as a quintessential component in the world of Deep Groove Radial Ball Bearings. The empirical evidence and real-world applications affirm that choosing the 6203-RSC3 bearing is a testament to embracing engineering excellence.

Maintenance and Best Practices

Introduction: Nurturing Brilliance

In the intricate world of Deep Groove Radial Ball Bearings, the 6203-RSC3 bearing stands out not only for its initial brilliance but also for its potential for sustained excellence. will delve into the crucial aspects of maintenance and best practices that contribute to unraveling the enduring engineering marvel encapsulated in the 6203-RSC3 bearing.

Understanding the Importance of Maintenance

Proper _maintenance_ is the cornerstone of preserving the brilliance of the 6203-RSC3 bearing. Regular upkeep ensures that the bearing continues to function at its optimal level, maintaining efficiency and reliability throughout its operational life. Neglecting maintenance can lead to premature wear, increased friction, and potential failures, diminishing the overall performance.

Key Maintenance Routines

To unlock the full potential of the 6203-RSC3 bearing, it's essential to adhere to specific maintenance routines:

|

Lubrication: The Lifeblood of Bearings |

Lubrication_ plays a pivotal role in sustaining the brilliance of the 6203-RSC3 bearing. Regularly checking and replenishing lubricants, while ensuring the right type and quantity, prevents friction, reduces heat buildup, and extends the bearing's lifespan. |

|

Inspection: Identifying Early Signs

|

Regular inspection_ is crucial for spotting potential issues before they escalate. Monitoring for unusual noise, vibration, or any irregularities in rotation helps in early detection of problems, enabling timely corrective measures. |

|

Environmental Considerations: Shielding Brilliance |

The operational environment significantly impacts bearing performance. Implementing measures to protect against contaminants, excessive moisture, and extreme temperatures ensures the 6203-RSC3 bearing retains its brilliance even in challenging conditions. |

Best Practices for Optimal Performance

Beyond routine maintenance, certain best practices contribute to unlocking the full potential of 6203-RSC3 bearings:

Proper Installation: Foundation for Brilliance

_Correct installation_ is the foundation for optimal bearing performance. Ensuring proper alignment and appropriate fits during installation minimizes stress on the bearing, enhancing its efficiency and extending its lifespan.

Load Management: Balancing Act

Understanding and _managing loads_ appropriately is vital. Avoiding excessive loads and ensuring a balanced distribution contribute to sustained brilliance and prevent premature wear.

Conclusion: Sustaining Brilliance

As we conclude our exploration into maintenance and best practices, it becomes evident that the brilliance of the 6203-RSC3 bearing is not only a product of advanced engineering but also a result of meticulous care. By incorporating these maintenance routines and best practices, users can ensure the prolonged brilliance of 6203-RSC3 bearings, making them a reliable and enduring component in the realm of Deep Groove Radial Ball Bearings.

Maintenance and Best Practices

Introduction: Nurturing Brilliance

In the intricate world of Deep Groove Radial Ball Bearings, the 6203-RSC3 bearing stands out not only for its initial brilliance but also for its potential for sustained excellence. will delve into the crucial aspects of maintenance and best practices that contribute to unraveling the enduring engineering marvel encapsulated in the 6203-RSC3 bearing.

Understanding the Importance of Maintenance

Proper _maintenance_ is the cornerstone of preserving the brilliance of the 6203-RSC3 bearing. Regular upkeep ensures that the bearing continues to function at its optimal level, maintaining efficiency and reliability throughout its operational life. Neglecting maintenance can lead to premature wear, increased friction, and potential failures, diminishing the overall performance.

Key Maintenance Routines

To unlock the full potential of the 6203-RSC3 bearing, it's essential to adhere to specific maintenance routines:

Lubrication: The Lifeblood of Bearings

_Lubrication_ plays a pivotal role in sustaining the brilliance of the 6203-RSC3 bearing. Regularly checking and replenishing lubricants, while ensuring the right type and quantity, prevents friction, reduces heat buildup, and extends the bearing's lifespan.

Inspection: Identifying Early Signs

_Regular inspection_ is crucial for spotting potential issues before they escalate. Monitoring for unusual noise, vibration, or any irregularities in rotation helps in early detection of problems, enabling timely corrective measures.

Environmental Considerations: Shielding Brilliance

The operational environment significantly impacts bearing performance. Implementing measures to protect against contaminants, excessive moisture, and extreme temperatures ensures the 6203-RSC3 bearing retains its brilliance even in challenging conditions.

Best Practices for Optimal Performance

Beyond routine maintenance, certain best practices contribute to unlocking the full potential of 6203-RSC3 bearings:

Proper Installation: Foundation for Brilliance

_Correct installation_ is the foundation for optimal bearing performance. Ensuring proper alignment and appropriate fits during installation minimizes stress on the bearing, enhancing its efficiency and extending its lifespan.

Load Management: Balancing Act

Understanding and _managing loads_ appropriately is vital. Avoiding excessive loads and ensuring a balanced distribution contribute to sustained brilliance and prevent premature wear.

Conclusion: Sustaining Brilliance

As we conclude our exploration into maintenance and best practices, it becomes evident that the brilliance of the 6203-RSC3 bearing is not only a product of advanced engineering but also a result of meticulous care. By incorporating these maintenance routines and best practices, users can ensure the prolonged brilliance of 6203-RSC3 bearings, making them a reliable and enduring component in the realm of Deep Groove Radial Ball Bearings.

FAQs: Common Questions About 6203-RSC3 - Deep Groove Radial Ball Bearings

Introduction to Frequently Asked Questions

we delve into common queries regarding the 6203-RSC3 Deep Groove Radial Ball Bearings, aiming to provide comprehensive answers that unravel the engineering marvel behind these bearings.

What Sets 6203-RSC3 Bearings Apart?

Answer: The brilliance of 6203-RSC3 bearings lies in their deep groove radial ball bearing design, offering precision engineering that sets them apart. This design enhances load capacity, speed, and overall performance compared to standard bearings.

How Versatile Are 6203-RSC3 Bearings?

Answer: These bearings showcase exceptional versatility, finding applications across various industries. From industrial machinery to automotive systems, the 6203-RSC3 bearings adapt seamlessly, demonstrating their adaptability and reliability.

What Technological Innovations Are Integrated?

Answer: Technological advancements in 6203-RSC3 bearings contribute significantly to their performance. The bearings incorporate cutting-edge technologies that enhance load distribution, reduce friction, and ensure optimal functioning even under high-speed conditions.

How Do I Maintain 6203-RSC3 Bearings for Longevity?

Answer: Proper maintenance is crucial for the sustained brilliance of 6203-RSC3 bearings. Regular lubrication, monitoring for wear, and following manufacturer-recommended maintenance routines are key practices to ensure extended lifespan and optimal performance.

Can 6203-RSC3 Bearings Withstand Heavy Loads?

Answer: Yes, these bearings are designed to handle both radial and axial loads efficiently. Their robust construction and advanced materials make them capable of withstanding heavy loads, contributing to their reliability in various applications.

Are 6203-RSC3 Bearings Environmentally Resilient?

Answer: Indeed, these bearings exhibit resilience in diverse environments. Their engineering considers factors like heat resistance and contamination prevention, making them suitable for challenging conditions across industries.

What Impact Do 6203-RSC3 Bearings Have on Efficiency?

Answer: The impact is profound. These bearings play a crucial role in driving efficiency by ensuring smooth operations in machinery. Their precision design and enduring performance contribute significantly to the overall efficiency of mechanical systems.

Conclusion: Unveiling the Brilliance Through FAQs

As we address common questions, it becomes evident that the 6203-RSC3 bearings are not just components; they are engineering marvels with a far-reaching impact on various industries. The FAQs unravel the intricacies of these bearings, showcasing their versatility, technological innovations, and enduring brilliance in the realm of deep groove radial ball bearings.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings