Home> Bearing Technology> Precision Engineering Solutions: The Impact of 6307-2RZ Bearings in Machinery

1 Introduction

Precision engineering plays a crucial role in ensuring the optimal performance and reliability of machinery across various industries. From automotive to aerospace, precision engineering solutions are indispensable for meeting stringent quality standards and achieving desired outcomes. At the heart of many precision machines lies the intricate mechanism of bearings, which facilitate smooth movement and minimize friction. Among these bearings, the 6307-2RZ stands out for its exceptional performance and reliability, making it a cornerstone in modern machinery.

In today's fast-paced industrial landscape, where efficiency and precision are paramount, the choice of bearings can significantly impact the overall performance of machinery. The 6307-2RZ bearing, with its high-speed capabilities and deep groove ball design, has emerged as a preferred solution for numerous applications, ranging from electric motors to gearboxes. Understanding the impact of 6307-2RZ bearings in machinery is essential for engineers, manufacturers, and stakeholders alike, as it underscores the importance of leveraging advanced technology for optimal results.

2 Understanding 6307-2RZ Bearings

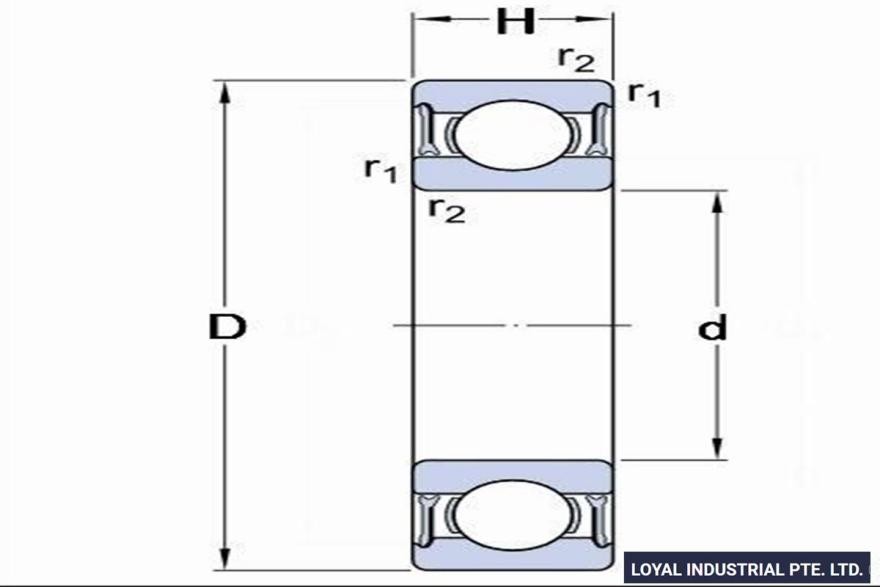

6307-2RZ bearings are precision-engineered components that play a pivotal role in various machinery applications. Comprising high-speed deep groove ball bearings, they are specifically designed to withstand heavy loads and operate efficiently even at high speeds. These bearings typically consist of an inner and outer ring, a cage, and ball bearings arranged in a deep groove configuration.

Key Features and Specifications:

|

Material Composition |

6307-2RZ bearings are often made from high-quality steel, ensuring durability and resistance to wear under demanding conditions. |

|

Design |

The deep groove design of 6307-2RZ bearings allows for smooth operation and efficient distribution of loads, reducing friction and heat generation. |

|

Sealing Mechanism |

The 2RZ designation indicates that the bearings feature non-contact rubber seals on both sides, providing effective protection against contamination and retaining lubrication. |

|

Size |

These bearings typically have a bore diameter of 35 mm, an outer diameter of 80 mm, and a width of 21 mm, although variations may exist based on specific requirements. |

|

Load Capacity |

With their robust construction and precision engineering, 6307-2RZ bearings exhibit high radial and axial load-carrying capacities, making them suitable for a wide range of applications. |

Comparison with Other Bearings:

When compared to alternative bearing options such as 6307-2RS or open bearings, 6307-2RZ bearings offer distinct advantages. While 6307-2RS bearings feature contact seals, 6307-2RZ bearings utilize non-contact rubber seals, reducing friction and energy loss. Additionally, the sealed design of 6307-2RZ bearings provides enhanced protection against contamination, prolonging bearing life and reducing maintenance requirements. Compared to open bearings, 6307-2RZ bearings offer superior protection against dust, dirt, and moisture ingress, making them ideal for harsh operating environments.

Brands and Variants of 6307-2RZ Bearings

Below is a comparison table highlighting different brands and their variants of 6307-2RZ bearings, along with key differentiators:

|

Brand |

Key Features |

Advantages |

Disadvantages |

|

SKF |

- High-quality steel construction |

- Excellent durability and longevity |

- Higher initial cost |

|

NSK |

- Advanced sealing technology |

- Superior resistance to contaminants |

- Slightly lower load capacity than competitors |

|

FAG |

- Precision engineering for optimal performance |

- Wide operating temperature range |

- May require more frequent maintenance |

|

NTN |

- Diverse range of applications compatibility |

- Cost-effective solution for various industries |

- May not offer the same level of precision |

|

Timken |

- Enhanced load capacity |

- Exceptional performance under heavy loads |

- Limited availability in certain regions |

|

Nachi |

- High-speed capabilities |

- Smooth operation even at elevated speeds |

- Less commonly used in certain industrial sectors |

|

Koyo |

- Robust design for harsh environments |

- Reliable performance in challenging conditions |

- Limited aftermarket support in some regions |

In summary, 6307-2RZ bearings represent a reliable and efficient solution for machinery applications requiring high-speed, precision operation. Their advanced design, coupled with robust construction and effective sealing mechanisms, ensures optimal performance and longevity, contributing significantly to the overall efficiency and reliability of industrial machinery.

3 The Role of 6307-2RZ Bearings in Machinery

The integration of 6307-2RZ bearings into machinery systems has a profound impact on performance, efficiency, and overall operational reliability. These precision-engineered components are specifically designed to meet the demanding requirements of modern industrial applications, offering numerous advantages over traditional bearing solutions.

Impact on Machinery Performance and Efficiency:

6307-2RZ bearings are engineered to deliver exceptional performance under high-speed and heavy-load conditions, making them ideal for a wide range of machinery applications. Their deep groove ball design ensures smooth operation and efficient power transmission, resulting in reduced friction and minimal energy loss. By minimizing frictional resistance, 6307-2RZ bearings contribute to enhanced machinery performance, enabling higher speeds, improved accuracy, and increased productivity.

Case Studies and Examples:

Numerous industries rely on 6307-2RZ bearings to achieve optimal performance in their machinery systems. For instance, in the automotive sector, these bearings are commonly used in engine components, transmissions, and wheel hubs to ensure reliable operation and long service life. Similarly, in the manufacturing industry, 6307-2RZ bearings are employed in conveyor systems, robotic arms, and machining equipment, where precision and efficiency are paramount. Case studies from these industries demonstrate the significant impact of 6307-2RZ bearings on machinery reliability, uptime, and overall operational efficiency.

Advantages and Benefits:

The adoption of 6307-2RZ bearings offers several advantages for machinery manufacturers and end-users alike. One key benefit is their robust construction and high-quality materials, which result in extended bearing life and reduced maintenance requirements. Additionally, the sealed design of 6307-2RZ bearings provides superior protection against contaminants such as dust, dirt, and moisture, ensuring consistent performance even in harsh operating environments. Furthermore, their compatibility with standard mounting dimensions and interchangeability with existing bearing systems make them a cost-effective solution for machinery upgrades and retrofits.

In conclusion, 6307-2RZ bearings play a vital role in enhancing the performance, efficiency, and reliability of machinery across various industries. By leveraging their advanced design and precision engineering, manufacturers can achieve higher levels of productivity, while end-users benefit from improved uptime and lower lifecycle costs.

4 Challenges and Solutions

6307-2RZ bearings, while renowned for their precision engineering and reliability, are not without their challenges when integrated into machinery applications. Understanding these challenges and implementing effective solutions is crucial to ensure optimal performance and longevity of these bearings.

Common Challenges:

One of the primary challenges encountered with 6307-2RZ bearings is the risk of contamination ingress. Dust, dirt, and moisture can infiltrate the bearing seals, leading to increased friction, wear, and potential failure. Additionally, inadequate lubrication or improper handling during installation can contribute to premature bearing wear and reduced performance. Furthermore, in high-speed applications, issues such as heat generation and insufficient cooling may pose challenges to bearing operation and lifespan.

Strategies and Solutions:

Addressing these challenges requires a proactive approach to maintenance and handling. Regular inspection and cleaning of bearing seals can help prevent contamination buildup and maintain optimal sealing performance. Utilizing high-quality lubricants and following manufacturer recommendations for lubrication intervals and methods are essential for reducing friction and minimizing wear. Proper installation techniques, including correct alignment and preload adjustment, are also critical for ensuring optimal bearing performance and longevity.

In high-speed applications, ensuring adequate cooling mechanisms, such as proper ventilation or the use of cooling systems, can help mitigate heat-related issues and prolong bearing life. Additionally, investing in advanced sealing solutions or bearing coatings designed to repel contaminants can provide enhanced protection in harsh operating environments.

Importance of Maintenance and Proper Handling:

Maximizing the lifespan of 6307-2RZ bearings requires diligent maintenance practices and proper handling throughout their lifecycle. Routine inspections, lubrication, and cleaning procedures should be performed to detect and address any potential issues early on. Furthermore, providing training to personnel involved in bearing installation and maintenance ensures proper handling practices are followed, reducing the risk of damage or premature failure.

By prioritizing maintenance and adopting proactive strategies to address common challenges, manufacturers and end-users can optimize the performance and longevity of 6307-2RZ bearings in machinery applications. Investing in proper maintenance and handling not only enhances bearing reliability but also contributes to overall machinery efficiency and productivity.

5 Factors Affecting the Performance of 6307-2RZ Bearings

6307-2RZ bearings are integral components in various machinery applications, but their performance can be influenced by several factors. Understanding and addressing these factors are essential to ensure optimal functionality and longevity of the bearings.

|

Environmental Factors |

The operating environment plays a significant role in determining the performance of 6307-2RZ bearings. Factors such as temperature fluctuations, humidity levels, and exposure to contaminants can impact bearing operation. Extreme temperatures can affect bearing lubrication properties and material integrity, leading to accelerated wear and potential failure. High humidity levels may contribute to corrosion or rust formation, compromising bearing performance over time. Contaminants such as dust, dirt, or chemicals can infiltrate bearing seals, increasing friction and reducing efficiency. Employing appropriate sealing solutions and implementing regular maintenance practices are essential to protect 6307-2RZ bearings from adverse environmental conditions.

|

|

Maintenance and Lubrication Requirements |

Proper maintenance and lubrication are crucial for the optimal functioning of 6307-2RZ bearings. Regular inspection and cleaning of bearing seals help prevent contamination buildup and ensure effective sealing performance. Lubrication plays a vital role in reducing friction and wear between bearing components. Using the correct type and amount of lubricant, as recommended by the manufacturer, helps maintain smooth operation and prolong bearing life. Lubrication intervals should be established based on operating conditions and monitored regularly to ensure adequate lubrication levels.

|

|

Challenges and Limitations |

Despite their robust design, 6307-2RZ bearings may encounter challenges and limitations in certain applications. High-speed or heavy-load conditions can put additional stress on the bearings, leading to increased wear and potential fatigue failure. Improper handling during installation or maintenance can result in damage to bearing components, affecting performance and reliability. Inadequate lubrication or contamination ingress can also contribute to premature bearing failure. However, these challenges can be mitigated through proper installation procedures, regular maintenance practices, and adherence to recommended operating conditions.

|

In conclusion, various factors, including environmental conditions, maintenance practices, and potential challenges, can affect the performance of 6307-2RZ bearings in machinery applications. By understanding these factors and implementing effective mitigation strategies, manufacturers and end-users can optimize bearing performance, extend lifespan, and ensure reliable operation in diverse industrial settings.

6 Conclusion

In conclusion, precision engineering solutions are paramount in ensuring the efficient and reliable operation of machinery across various industries. Within this context, the role of 6307-2RZ bearings cannot be overstated. These high-speed deep groove ball precision motor bearings play a crucial role in facilitating smooth movement and minimizing friction within machinery systems.

Recap of Precision Engineering:

Precision engineering lies at the heart of modern machinery, enabling the attainment of high levels of accuracy, efficiency, and reliability. From automotive to aerospace, precision-engineered components form the backbone of industrial processes, driving innovation and progress.

Summary of the Role and Benefits of 6307-2RZ Bearings:

6307-2RZ bearings offer unparalleled performance and reliability in machinery applications. With their advanced design and precision manufacturing, these bearings provide efficient power transmission, reduced friction, and extended service life. They are widely utilized across various industries, including automotive, manufacturing, and robotics, where precision and reliability are paramount.

Final Thoughts:

As we look to the future of machinery engineering, the importance of utilizing high-quality bearings like the 6307-2RZ cannot be understated. By investing in precision-engineered components, manufacturers can enhance machinery performance, optimize productivity, and minimize downtime. Moreover, the reliability and longevity of 6307-2RZ bearings contribute to overall operational efficiency and cost-effectiveness, making them a valuable asset in any industrial setting.

In conclusion, precision engineering solutions, exemplified by the use of 6307-2RZ bearings, play a critical role in shaping the modern industrial landscape. By embracing innovation and leveraging high-quality components, manufacturers can continue to push the boundaries of efficiency, reliability, and performance in machinery applications.

7 FAQs: Common Questions About 6307-2RZ Bearings

As the cornerstone of machinery operation, 6307-2RZ bearings often prompt questions regarding their performance, maintenance, and application. Here are some frequently asked questions to provide clarity on this essential component:

1. What is the significance of 6307-2RZ bearings in machinery?

6307-2RZ bearings are high-speed deep groove ball precision motor bearings designed to facilitate smooth movement and minimize friction within machinery systems. Their precision engineering and robust construction make them indispensable components in various industrial applications, ensuring optimal performance and reliability.

2. How do 6307-2RZ bearings differ from other types of bearings?

6307-2RZ bearings feature a deep groove ball design with non-contact rubber seals on both sides, providing effective protection against contamination and retaining lubrication. This design distinguishes them from other bearing types such as 6307-2RS, which feature contact seals, and open bearings, which lack seals altogether.

3. How should 6307-2RZ bearings be maintained for optimal performance?

Proper maintenance practices are essential for maximizing the lifespan and performance of 6307-2RZ bearings. This includes regular inspection and cleaning of bearing seals to prevent contamination buildup, as well as lubrication according to manufacturer recommendations to reduce friction and wear.

4. What challenges may arise when using 6307-2RZ bearings, and how can they be addressed?

Common challenges associated with 6307-2RZ bearings include contamination ingress, inadequate lubrication, and potential heat generation in high-speed applications. These challenges can be mitigated through proactive maintenance, proper handling during installation, and adherence to recommended operating conditions.

5. Are 6307-2RZ bearings suitable for all machinery applications?

While 6307-2RZ bearings offer versatile performance characteristics, their suitability for specific applications depends on factors such as operating conditions, load requirements, and environmental factors. Consulting with bearing experts and considering application-specific requirements is crucial for determining the suitability of 6307-2RZ bearings.

These FAQs aim to address common inquiries regarding 6307-2RZ bearings and their application in machinery. For further information or specific queries, consulting with bearing experts or reputable suppliers is recommended.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings