Home> Bearing Technology> A Deep Dive into the Design and Functionality of 6307-2RZ Bearings

1 Introduction to 6307-2RZ Bearings

6307-2RZ bearings represent a critical component within industrial machinery, facilitating smooth and efficient operation across various sectors.

Definition and Overview

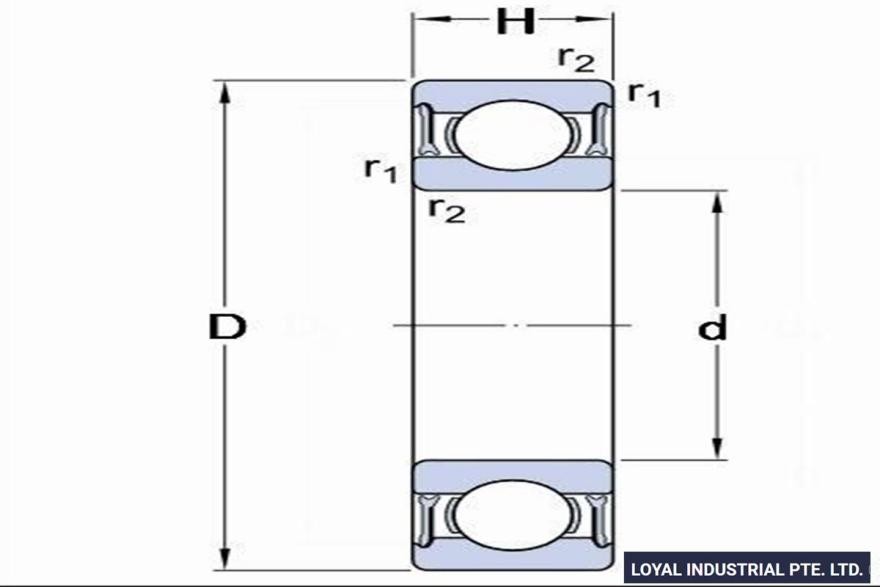

6307-2RZ bearings belong to the category of deep groove ball bearings, renowned for their versatility and robustness in handling radial and axial loads. They feature an inner and outer ring with deep raceway grooves, providing excellent support for high-speed rotation and precise alignment.

Importance of Bearings in Industrial Machinery

Bearings serve as the backbone of industrial machinery, enabling the smooth movement of rotating components such as shafts, wheels, and gears. They mitigate friction, reduce heat generation, and support heavy loads, thus optimizing the overall efficiency and reliability of machinery in various industrial applications.

Below is a comparison table highlighting different brands and their variants of 6307-2RZ bearings, along with key differentiators:

|

Brand |

Key Features |

Advantages |

Disadvantages |

|

SKF |

- High-quality steel construction |

- Excellent durability and longevity |

- Higher initial cost |

|

NSK |

- Advanced sealing technology |

- Superior resistance to contaminants |

- Slightly lower load capacity than competitors |

|

FAG |

- Precision engineering for optimal performance |

- Wide operating temperature range |

- May require more frequent maintenance |

|

NTN |

- Diverse range of applications compatibility |

- Cost-effective solution for various industries |

- May not offer the same level of precision |

|

Timken |

- Enhanced load capacity |

- Exceptional performance under heavy loads |

- Limited availability in certain regions |

|

Nachi |

- High-speed capabilities |

- Smooth operation even at elevated speeds |

- Less commonly used in certain industrial sectors |

|

Koyo |

- Robust design for harsh environments |

- Reliable performance in challenging conditions |

- Limited aftermarket support in some regions |

2 Materials and Construction of 6307-2RZ Bearings

We will delve into the materials and construction methods employed in the manufacturing of 6307-2RZ bearings, shedding light on their intricate design and precision engineering.

|

Overview of Materials |

6307-2RZ bearings are crafted using high-quality materials selected for their durability, corrosion resistance, and performance under demanding conditions. Common materials include chrome steel (AISI 52100), stainless steel, and ceramic. Chrome steel, renowned for its hardness and wear resistance, remains the predominant choice for traditional bearings. Stainless steel variants offer enhanced corrosion resistance, making them suitable for applications exposed to moisture or harsh environments. Ceramic bearings, although less common, boast exceptional hardness, low friction, and resistance to thermal expansion. |

|

Discussion on Construction Process |

The construction of 6307-2RZ bearings involves meticulous precision machining to ensure optimal performance and reliability. The process typically begins with the formation of the inner and outer rings through forging or casting, followed by precision grinding to achieve the desired dimensions and surface finish. The raceway grooves, critical for bearing functionality, are meticulously formed using specialized machining techniques. Assembly of the bearing components is conducted with utmost care to minimize internal clearances and ensure smooth operation. |

|

Impact on Performance and Durability |

The choice of materials and construction methods significantly influences the performance and durability of 6307-2RZ bearings. High-quality materials and precision machining contribute to reduced friction, minimal wear, and extended service life. Bearings crafted from premium materials exhibit superior resistance to corrosion, fatigue, and shock loads, making them ideal for demanding industrial applications. Furthermore, precise construction ensures consistent performance, minimal noise, and enhanced reliability, thereby optimizing machinery operation and productivity. |

By understanding the materials and construction techniques employed in the manufacturing of 6307-2RZ bearings, we gain valuable insights into their robustness, reliability, and suitability for various industrial applications.

3 Functionality and Working Principles of 6307-2RZ Bearings

We will explore the intricate functionality and working principles of 6307-2RZ bearings, elucidating how these components operate within machinery to facilitate smooth and efficient performance.

|

Explanation of Operation |

6307-2RZ bearings play a crucial role in industrial machinery by supporting rotating shafts and reducing friction between moving parts. These bearings utilize a deep groove ball design, featuring precision-engineered raceways that guide the rotation of the inner and outer rings. The rolling elements, typically steel balls or ceramic rollers, transmit radial and axial loads while maintaining low frictional resistance. By minimizing friction, 6307-2RZ bearings ensure smooth rotation and prevent excessive wear, thus prolonging the lifespan of machinery components. |

|

Discussion on Functioning Principles |

The functioning principles of 6307-2RZ bearings revolve around load capacity, rotation speed, and operational efficiency. These bearings are designed to withstand radial loads (perpendicular to the shaft) and axial loads (parallel to the shaft) simultaneously, making them versatile for various applications. The load capacity of 6307-2RZ bearings depends on factors such as bearing size, material quality, and lubrication. Additionally, the rotation speed, or maximum operating velocity, determines the bearing's ability to accommodate high-speed machinery without compromising performance or safety. |

|

Importance of Lubrication and Sealing |

Proper lubrication and sealing are essential aspects of ensuring the optimal functionality and longevity of 6307-2RZ bearings. Lubricants, such as grease or oil, form a thin film between the bearing components, reducing friction and dissipating heat generated during operation. Effective sealing mechanisms prevent contaminants, moisture, and debris from infiltrating the bearing assembly, safeguarding against premature wear and corrosion. Regular maintenance, including lubrication checks and seal inspections, is paramount to uphold the performance and reliability of 6307-2RZ bearings in demanding industrial environments. |

By understanding the functionality and working principles of 6307-2RZ bearings, engineers and technicians can implement proper maintenance practices and optimize machinery performance for enhanced operational efficiency and productivity.

4 Applications of 6307-2RZ Bearings in Industrial Machinery

We will delve into the diverse applications of 6307-2RZ bearings across various industries, highlighting their significance in enhancing the performance and functionality of industrial machinery.

Overview of Industries and Applications

6307-2RZ bearings find extensive use across a wide range of industries due to their versatility, reliability, and precision engineering. In the automotive sector, these bearings are integral components of automotive transmissions, engines, and wheel hubs, where they facilitate smooth rotation and reduce friction to ensure optimal vehicle performance. Moreover, in the aerospace industry, 6307-2RZ bearings are employed in aircraft engines, landing gear systems, and flight control mechanisms, where their high-speed capabilities and exceptional durability are essential for safe and efficient flight operations. Additionally, in the manufacturing and heavy machinery sectors, these bearings play vital roles in conveyor systems, pumps, compressors, and power tools, contributing to the seamless operation of production processes and machinery functionalities.

Specific Roles and Functions

6307-2RZ bearings serve diverse functions depending on the machinery and equipment in which they are installed. In conveyor systems, these bearings support rotating shafts and conveyor rollers, enabling the smooth movement of materials along production lines. In pumps and compressors, they facilitate the transmission of rotational energy, ensuring efficient fluid transfer and pressure generation. Furthermore, in power tools such as electric drills and saws, 6307-2RZ bearings provide stability and precision during high-speed operation, enhancing the performance and user experience.

Examples of Machinery and Equipment

Numerous types of machinery and equipment benefit from the incorporation of 6307-2RZ bearings. Examples include CNC machines, where these bearings support spindle assemblies and guide the movement of cutting tools with precision and accuracy. In industrial fans and blowers, 6307-2RZ bearings enable reliable rotation of fan blades, ensuring optimal airflow and ventilation in manufacturing facilities. Additionally, in electric motors used in various applications, including pumps, compressors, and conveyor systems, these bearings facilitate smooth and efficient rotation of motor shafts, contributing to overall machinery performance and energy efficiency.

By understanding the diverse applications of 6307-2RZ bearings in industrial machinery, engineers and manufacturers can make informed decisions regarding bearing selection and integration, thereby optimizing machinery performance, reliability, and longevity.

5 Performance Benefits and Advantages of 6307-2RZ Bearings

We will explore the significant performance benefits and advantages associated with 6307-2RZ bearings, highlighting their crucial role in enhancing machinery efficiency, productivity, and overall performance.

Analysis of Performance Advantages

6307-2RZ bearings offer several key advantages that contribute to their superior performance in industrial applications. Firstly, their high-speed capability enables machinery to operate efficiently at elevated rotational speeds, resulting in enhanced productivity and throughput. Additionally, these bearings are known for their exceptional load-carrying capacity, allowing them to withstand heavy radial and axial loads without compromising performance or longevity. Moreover, the precision engineering and tight tolerances of 6307-2RZ bearings ensure smooth operation and minimal friction, reducing energy consumption and prolonging the lifespan of machinery components.

Impact on Machinery Efficiency and Productivity

The incorporation of 6307-2RZ bearings into industrial machinery has a profound impact on overall efficiency and productivity. By reducing friction and minimizing energy loss during operation, these bearings optimize power transmission and utilization, thereby increasing the efficiency of machinery systems. Furthermore, their robust construction and reliable performance enable continuous operation under demanding conditions, minimizing downtime and maximizing productivity in manufacturing and production environments.

Case Studies and Testimonials

Numerous case studies and testimonials from industry experts and manufacturers attest to the tangible benefits of using 6307-2RZ bearings in various applications. For instance, a leading automotive manufacturer reported a significant improvement in assembly line efficiency and product quality after upgrading to 6307-2RZ bearings in their robotic welding systems. Similarly, a major aerospace company witnessed a notable increase in aircraft engine reliability and performance following the adoption of these bearings in critical engine components. Such real-world examples serve as compelling evidence of the performance benefits and advantages offered by 6307-2RZ bearings across diverse industrial sectors.

By harnessing the performance benefits of 6307-2RZ bearings, businesses can optimize machinery efficiency, enhance productivity, and achieve sustainable competitive advantages in today's dynamic market landscape.

6 Maintenance and Care of 6307-2RZ Bearings

We will delve into the essential aspects of maintaining and caring for 6307-2RZ bearings, emphasizing the importance of proper maintenance practices to ensure optimal performance and longevity.

Guidelines for Proper Maintenance

Proper maintenance is crucial for maximizing the lifespan and performance of 6307-2RZ bearings. It involves several key steps, starting with regular inspections to check for signs of wear, damage, or contamination. Visual inspections should be conducted periodically to assess the condition of the bearings and identify any potential issues early on. Additionally, it is essential to follow manufacturer-recommended maintenance procedures and schedules to ensure compliance with industry standards and specifications.

Importance of Regular Inspection, Lubrication, and Replacement Intervals

Regular inspection, lubrication, and replacement intervals are vital aspects of 6307-2RZ bearing maintenance. Inspection involves assessing the condition of the bearings, including checking for proper alignment, smooth rotation, and signs of overheating or abnormal noise. Lubrication is critical for reducing friction and wear between bearing components, thereby extending their lifespan and preventing premature failure. It is essential to use the appropriate lubricants and apply them according to manufacturer guidelines to ensure optimal performance.

Tips for Extending Lifespan and Optimizing Performance

To extend the lifespan and optimize the performance of 6307-2RZ bearings, several best practices should be followed. Firstly, proper handling and storage are essential to prevent damage or contamination during transportation and storage. Bearings should be stored in a clean, dry environment and handled with care to avoid mishandling or rough treatment. Secondly, maintaining proper alignment and clearance is crucial for minimizing stress and ensuring smooth operation. Regular monitoring of operating conditions and environmental factors, such as temperature and humidity, can also help identify potential issues early and prevent damage or failure.

In conclusion, adhering to proper maintenance and care practices is essential for maximizing the performance, efficiency, and lifespan of 6307-2RZ bearings. By following guidelines for inspection, lubrication, and replacement intervals, businesses can ensure the reliable operation of machinery and equipment, minimize downtime, and reduce maintenance costs in the long run.

7 Conclusion

In conclusion, our deep dive into the design and functionality of 6307-2RZ bearings has shed light on several crucial aspects of these precision components.

Summary of Key Points

Throughout this exploration, we have examined the materials and construction of 6307-2RZ bearings, delving into their functionality and working principles, as well as their applications in industrial machinery. We've highlighted the performance benefits and advantages they offer, emphasizing the importance of proper maintenance and care to optimize their lifespan and performance.

Reflection on Importance

6307-2RZ bearings play a vital role in enhancing the efficiency, productivity, and overall performance of machinery across various industries. Their precision design and high-speed capabilities make them indispensable components in countless applications, from automotive to manufacturing.

Call to Action

As we conclude, it's evident that the evolution of bearing technologies, exemplified by 6307-2RZ bearings, continues to drive innovation and progress in the industrial sector. Therefore, it's imperative for businesses and industries to embrace and leverage these advancements, fostering continued exploration and utilization of advanced bearing technologies to propel machinery operations forward.

In essence, 6307-2RZ bearings represent not only the culmination of precision engineering but also the promise of enhanced machinery operations and industrial efficiency. Let us continue to harness the power of innovation and technology to drive success in the ever-evolving landscape of industrial machinery.

8 FAQs: Common Questions About 6307-2RZ

We'll address some common questions regarding 6307-2RZ bearings, providing clarity and insights into their design, functionality, and applications.

1. What does "6307-2RZ" signify in bearing terminology?

- The term "6307-2RZ" refers to a specific type of deep groove ball bearing. The "6307" indicates the bearing's size and dimensions, while "2RZ" signifies that it has two non-contact rubber seals on both sides to provide improved sealing and protection against contaminants.

2. What are the primary applications of 6307-2RZ bearings?

- 6307-2RZ bearings are commonly used in high-speed and precision applications, particularly in electric motors, machinery, automotive components, and industrial equipment. Their design and construction make them suitable for environments requiring reliable performance and minimal friction.

3. How do 6307-2RZ bearings contribute to machinery efficiency?

- 6307-2RZ bearings offer low friction and high-speed capabilities, reducing energy consumption and heat generation in machinery. Their precise construction and smooth operation contribute to overall machinery efficiency, leading to improved performance and productivity.

4. What maintenance practices are recommended for 6307-2RZ bearings?

- Proper maintenance is essential for maximizing the lifespan and performance of 6307-2RZ bearings. Regular inspection, lubrication with high-quality grease, and monitoring of operating conditions are recommended. Additionally, ensuring proper sealing to prevent contamination is crucial for optimal functionality.

5. How can I identify signs of bearing failure in 6307-2RZ bearings?

- Common indicators of bearing failure include abnormal noise, vibration, increased operating temperature, and reduced performance. Regular monitoring of these factors, along with visual inspection for signs of wear or damage, can help identify potential issues early and prevent costly downtime.

By addressing these frequently asked questions, we aim to provide a comprehensive understanding of 6307-2RZ bearings, empowering users to make informed decisions regarding their selection, usage, and maintenance.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings